Intelligent charging system and charging method of power car lithium battery pack

A technology of intelligent charging and lithium battery packs, applied in battery circuit devices, electric vehicles, collectors, etc., can solve D/A conversion output conversion errors, cannot effectively track lithium battery charging curves, and cannot simulate lithium battery constant voltage charging stage and other issues to achieve the effect of improving control accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, a battery pack with a nominal capacity of 40Ah, a nominal voltage of 345.6V, and a maximum charging voltage of 394.2V is taken as an example to describe the present invention in detail with reference to the accompanying drawings.

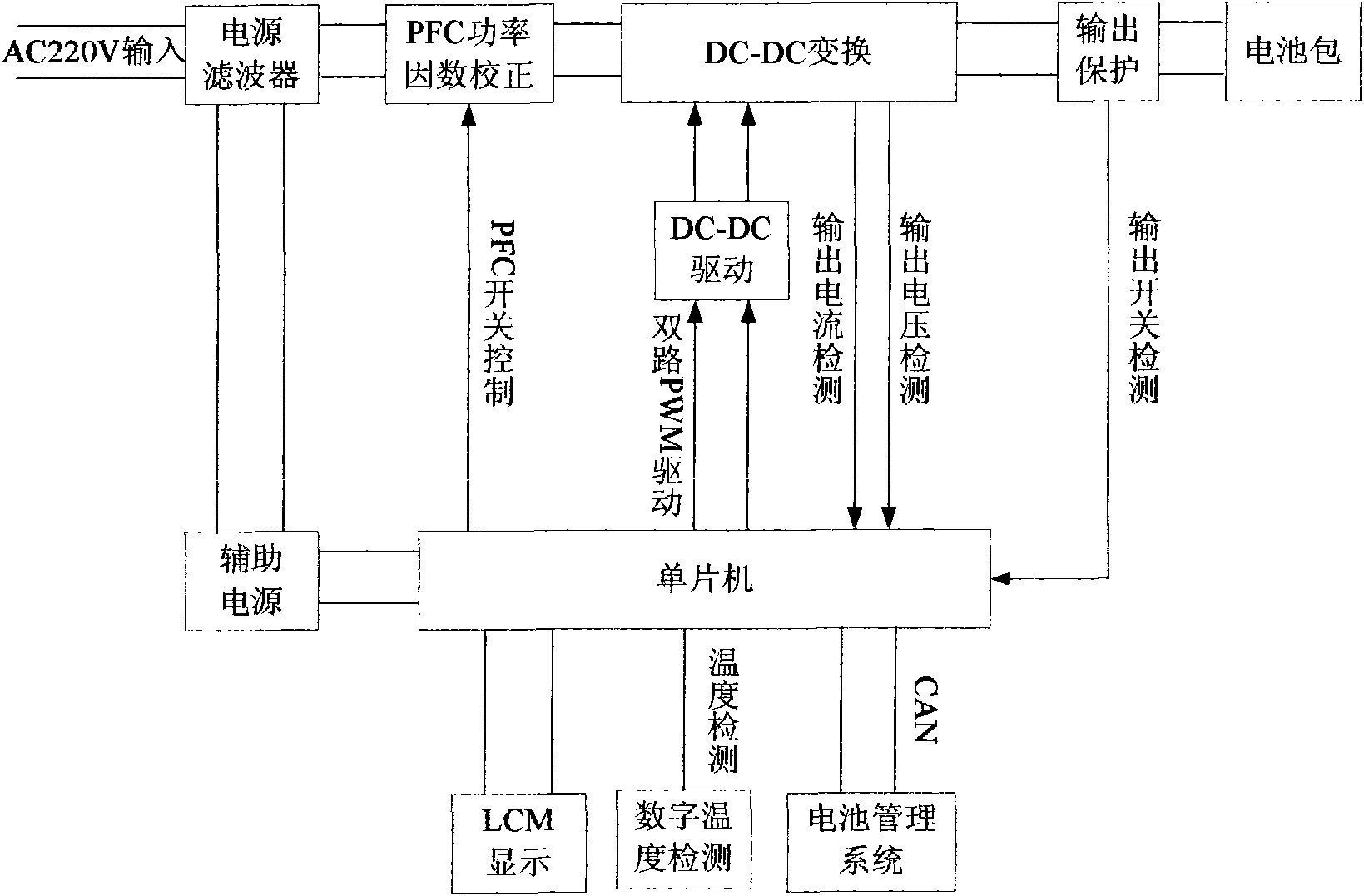

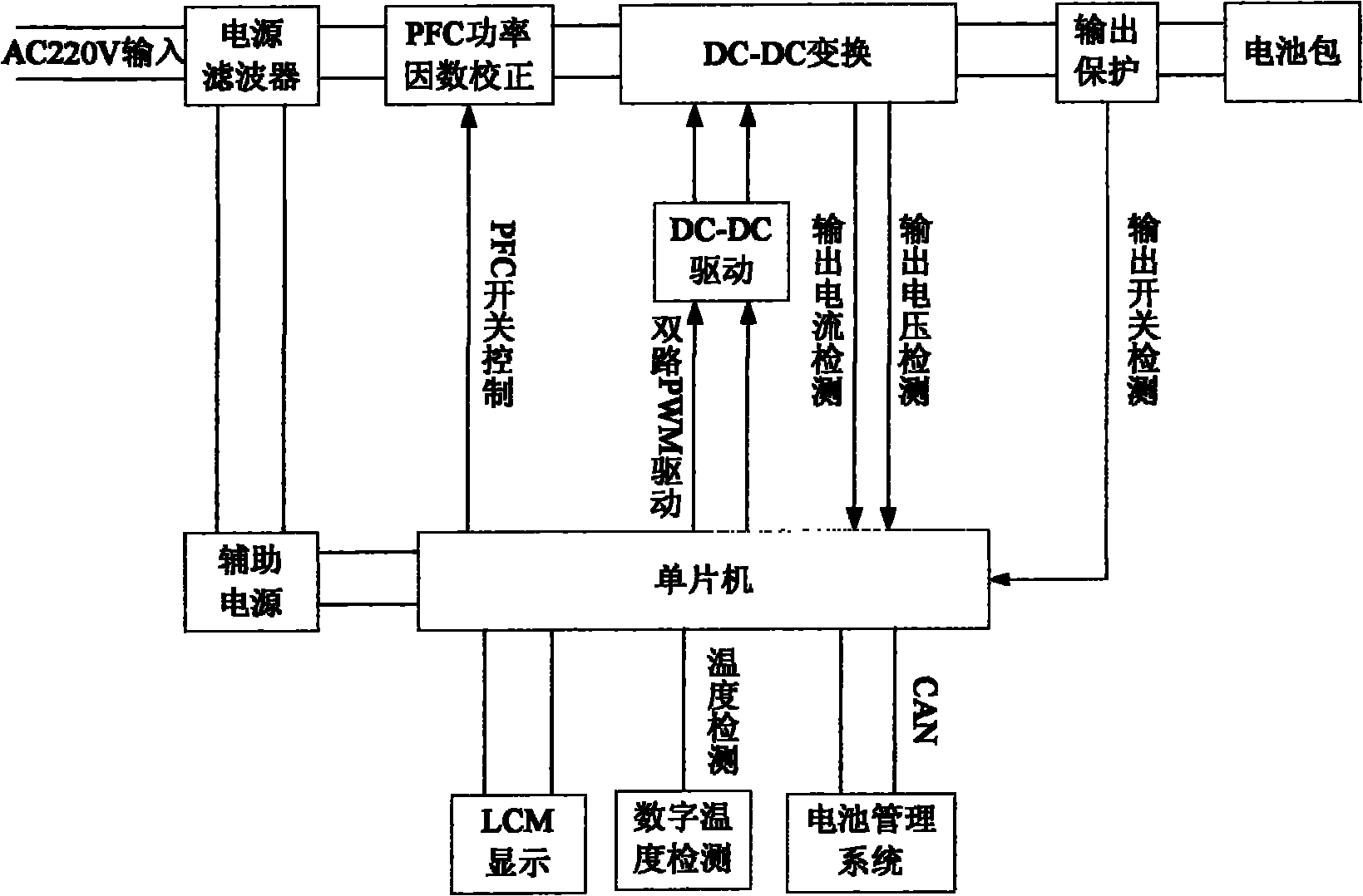

[0023] Such as figure 1 As shown, this system is mainly composed of a power filter module, a PFC power factor correction module, a DC-DC drive module, a DC-DC module, an output protection circuit, an auxiliary power supply circuit and a single-chip control unit. The PFC power factor correction module includes IR1150 module and LM339 module. IR1150 provides over-current protection. When an over-current fault occurs, the PFC and DC-DC modules are turned off. LM339 provides over-voltage, under-voltage, and over-temperature detection. When LM339 detects When the system is over-voltage, under-voltage, or over-temperature, the relevant signals are sent to the single-chip control unit, and the single-chip action closes the PFC and stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com