Nano indentation system based on scanning electron microscope

A nano-indentation, scanning electron microscope technology, applied in scanning probe technology, electromagnetic measurement device, electric/magnetic solid deformation measurement, etc. Reliable performance, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

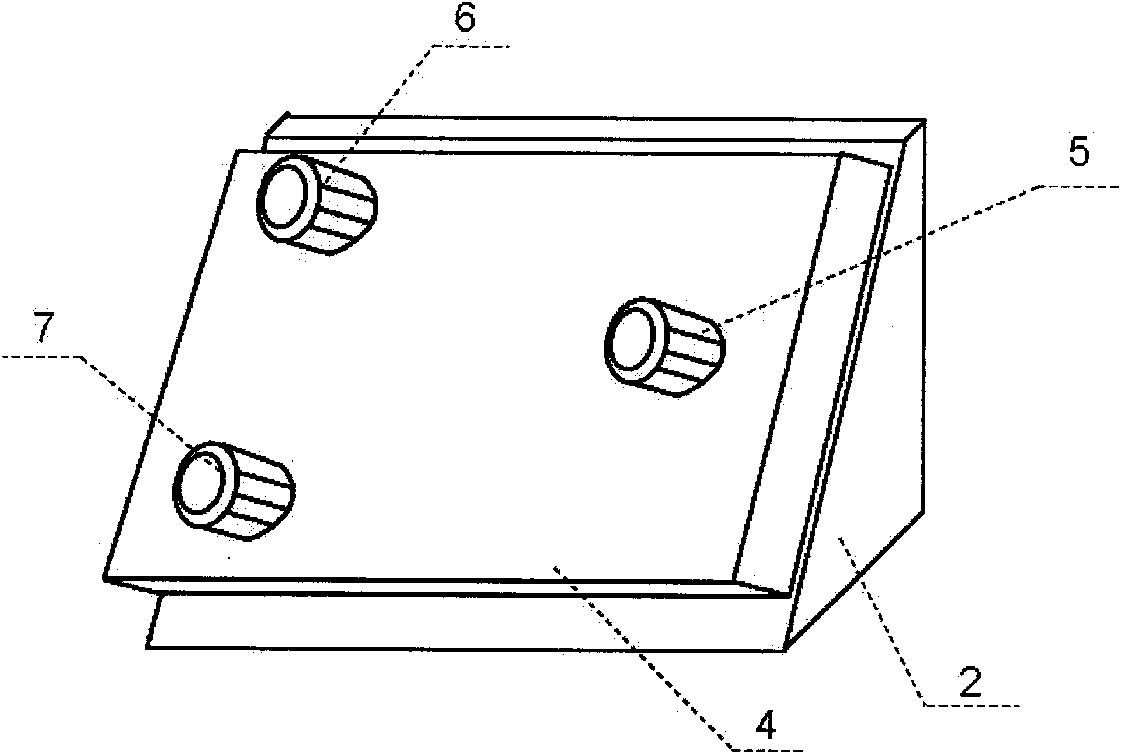

[0030] In order to achieve the above purpose, the nanoindentation instrument based on the scanning electron microscope is characterized in that it includes a base 1 and a sample base 2 fixed on one side of the base 1, and is fixed on the other side of the base 1 opposite to the sample base 2 The indentation head support seat 3. In order to facilitate the indentation operation on the sample while observing the sample in the scanning electron microscope, the shape of the sample base 2 is a right-angled trapezoid or a right-angled triangle. is the Z-axis direction, and the X, Y, Z three-axis directions are as follows figure 1 shown. The substrate 4 is fixed on the slope of the sample base 2 through an angle adjuster I5, an angle adjuster II6, and an angle adjuster III7. The angle adjuster I5 is close to the side edge of the substrate 4 and is located on the center line of the substrate 4. The angle adjuster II6 Form an equilateral triangle with the angle adjuster III7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com