Longquan celadon reinforced blank and preparation method of product thereof

The technology of celadon and blank is applied in the field of preparation of Longquan celadon reinforced blank and its products, which can solve the problems of low strength of Longquan celadon, and achieve the effects of increased sales profit, significant economic benefit and increased sales price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

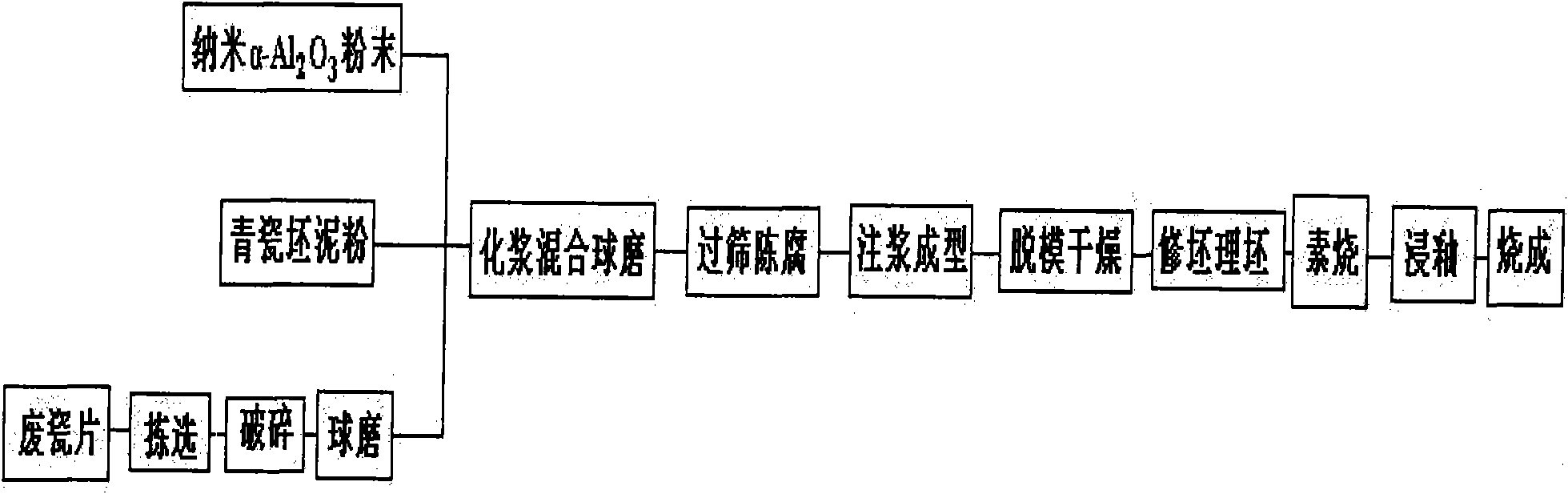

Method used

Image

Examples

Embodiment 1

[0035] Pass 82g of Longquan local celadon mud powder through a 200-mesh sieve, mix with 3g of 120-mesh waste porcelain powder and 15g of 40-80nm nano-α-Al 2 o 3 The powder is mixed and stirred evenly, and the slurry is turned into a slurry and stale (as a grouting material for standby).

[0036] Then grouting molding, after demoulding and drying, the billet is repaired to replenish water, and after natural drying, it is bisque fired at 700°C for 6 hours. Heat at 1350°C for 1 hour and fire.

[0037] The flexural strength of the obtained product was 79.67mpa.

Embodiment 2

[0039] Pass 77g of Longquan local celadon mud powder through a 200-mesh sieve, mix with 3g of 120-mesh waste porcelain powder and 20g of 40-80nm nano-α-Al 2 o 3 The powder is mixed and stirred evenly, and the slurry is turned into a slurry and stale (as a grouting material for standby).

[0040] Then grouting molding, after demoulding and drying, the billet is repaired to replenish water, and after natural drying, it is biscuit fired at 800 ° C for 6 hours. After the bisque fired body is dipped in glaze and dried, it is fired in a high-temperature liquefied gas kiln with a maximum temperature of 1360 ° C. ℃ for 1 hour and fired.

[0041] The flexural strength of the obtained product was 88.25mpa.

Embodiment 3

[0043] Pass 70g of Longquan local celadon mud powder through a 200-mesh sieve, mix with 2g of 120-mesh waste porcelain powder and 25g of 40-80nm nano-α-Al 2 o 3 The powder is mixed and stirred evenly, and the slurry is turned into a slurry and stale (as a grouting material for standby).

[0044] Then grouting molding, after demoulding and drying, the billet is repaired to replenish water, and after natural drying, it is bisque fired at 800°C for 6 hours. After the bisque fired billet is dipped in glaze and dried, it is then fired in a high-temperature liquefied gas kiln with a maximum temperature of 1380 °C. ℃ for 1 hour and fired.

[0045] The flexural strength of the obtained product was 103.06mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com