Injection molding machine with automatic label delivering system

An injection molding machine and label feeding technology, which is applied in the field of injection molding machines, can solve problems such as difficulty in meeting production development, low labeling accuracy, and slow labeling speed, and achieve the effects of novel structure, high labeling accuracy, and fast labeling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

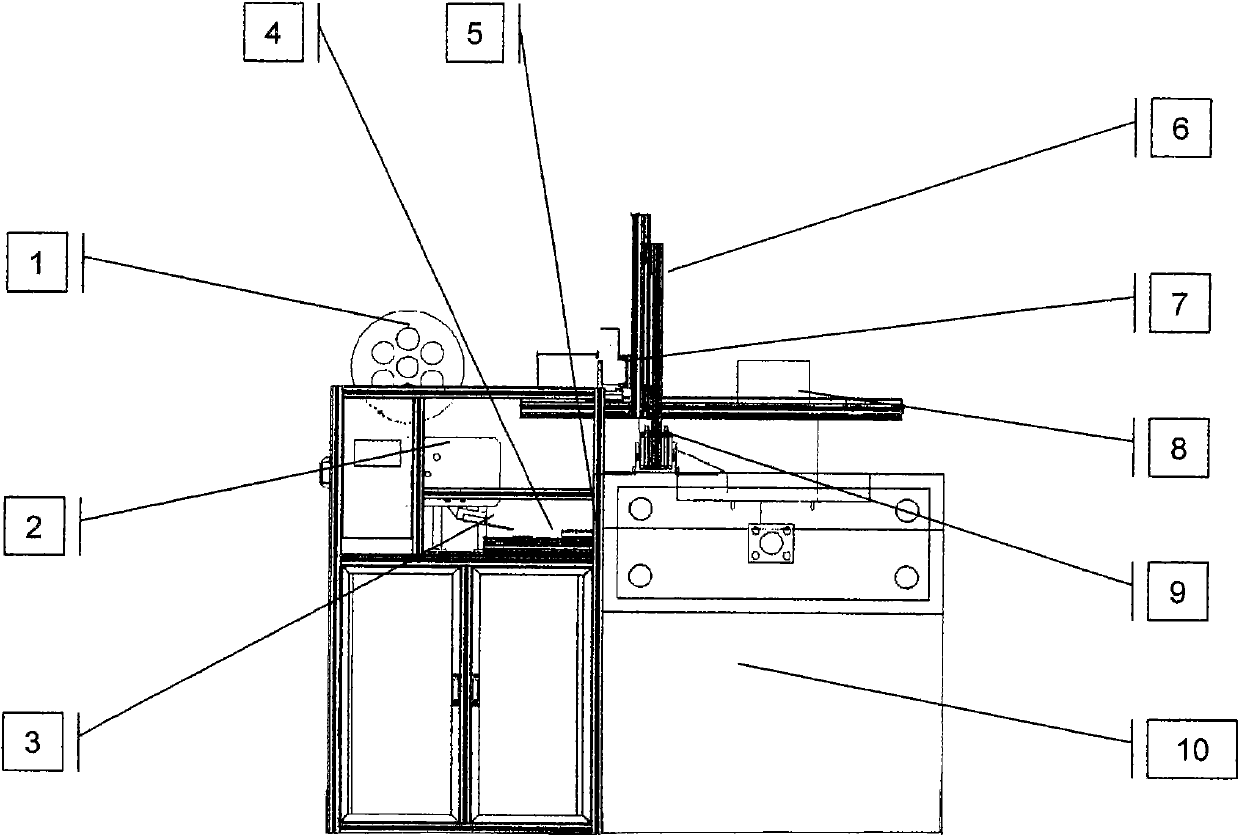

[0010] Such as figure 1 As shown, an injection molding machine with an automatic label feeding system includes a label roll unwinding device 1, a label transfer device 2, a label peeling part 3, a label transfer shaft 4, a label vacuum suction transfer device 5, a mechanical arm, and a label suction device. Cavity transfer device 9. The label transfer device is connected below the label roll unwinding device, and the label transfer device cooperates with the label transfer shaft and the label vacuum adsorption transfer device. arm. The mechanical arm is mainly composed of a robot Z-axis 6, a robot Y-axis 7, a robot X-axis 8 and a driving device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com