Rotary pump

A technology for motorized pumps and driven pumps, which is applied in the direction of machines/engines, pumps, pump devices, etc., which can solve the problems of technical extravagance, difficult vibration reduction measures, and insufficient use, so as to reduce air noise and solid noise emissions, reduce Accuracy requirements, effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

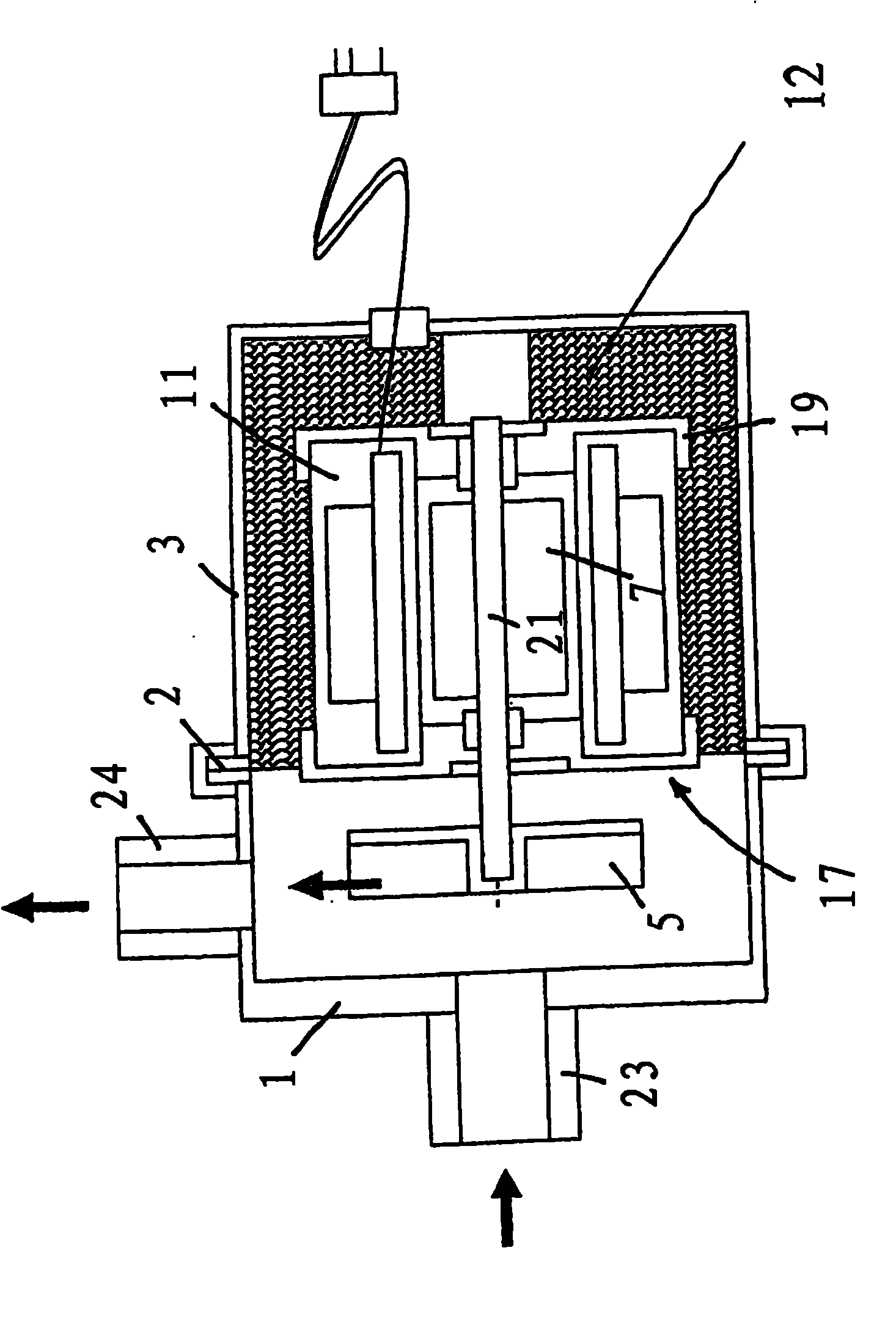

[0017] In each of the seven illustrated exemplary embodiments a rotary motor pump in the form of a wet rotor is involved. In this case, the motor stator 17 forms a cylindrical interior 18 through which the conveying fluid flows and in which the rotor 7 is mounted rotatably together with the motor shaft 21 . In this case, the stator 17 has windings 6 surrounding the space 18, these windings are sheathed by a thermosetting plastic or thermoplastic, so that the motor with its sheath 11 forms a unit from which the motor shaft 21 exits into the pump chamber , so that the impeller 5 of the pump is supported there.

[0018] On both sides of the jacket 11 , the motor stator 17 is surrounded by an inner motor housing 19 . However, this housing 19 can be omitted and can be replaced by the casing 11 . In all exemplary embodiments, the motor inner housing 19 forms part of the motor stator 17 .

[0019] The motor stator 17 is surrounded by the outer motor housing 3 at a distance such th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com