Full-glass dual-channel vacuum tube heat collector

A vacuum tube heat collector and dual-channel technology, which is applied to solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve the problems of split solar thermal application systems that cannot operate and increase investment costs. Achieve the effect of low cost, high cost performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: thermal medium: water

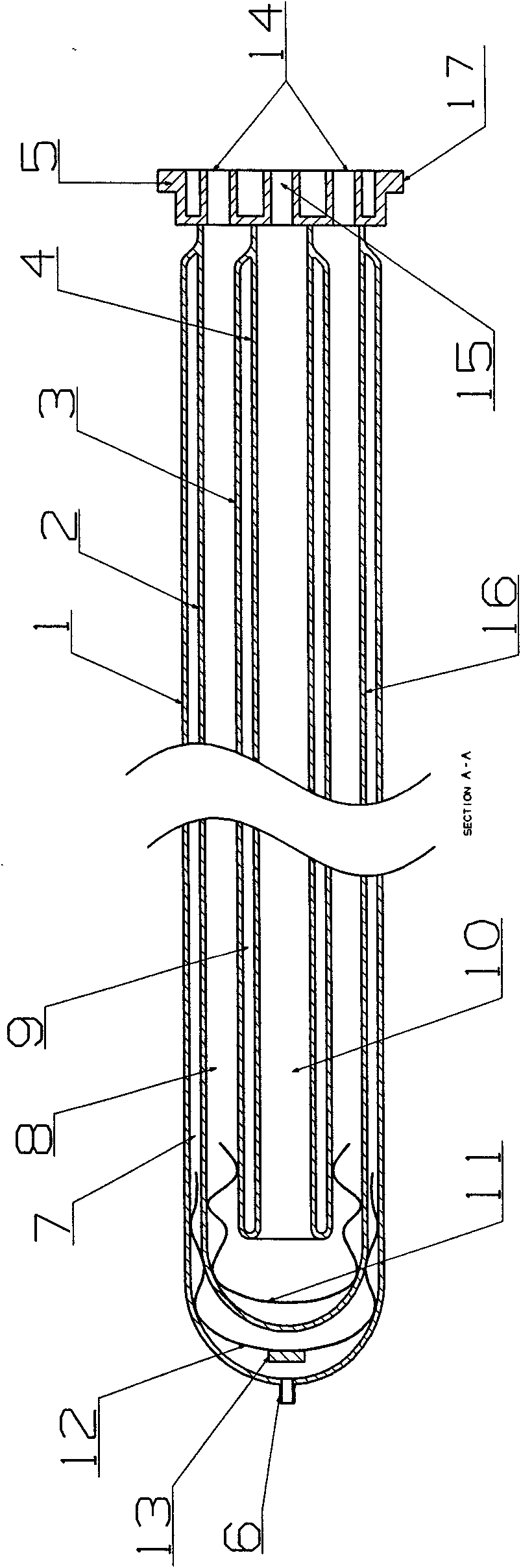

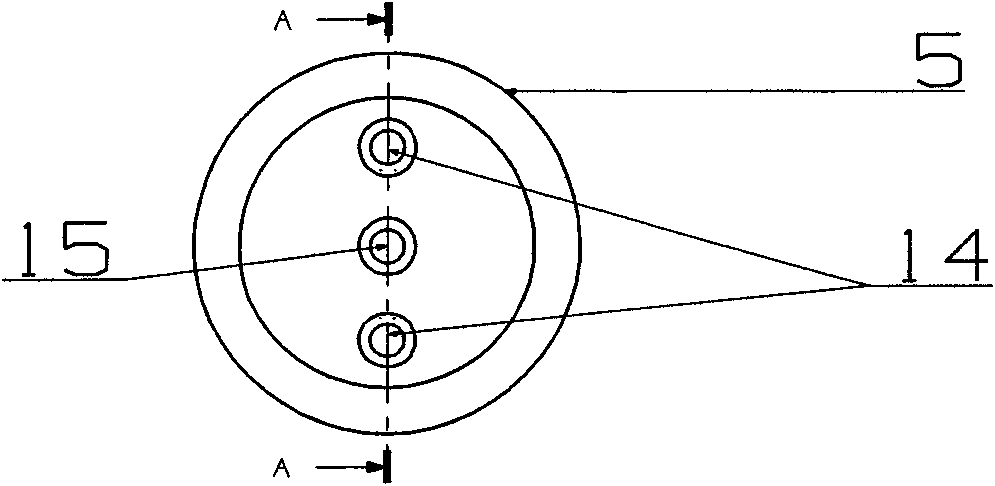

[0031] An all-glass double-channel vacuum tube heat collector, comprising an outer glass tube 1, a heat-absorbing glass tube 2, an insulating glass tube 3 and an inner glass tube 4, the outer glass tube 1, the heat-absorbing glass tube 2, the insulating glass tube 3 and the inner glass tube The top of the glass tube 4 is coaxially arranged and sealed on the glass flange 5 by high temperature fusion. A vacuum exhaust hole 6 is provided at the bottom of the outer glass tube 1. The outer glass tube 1, the heat-absorbing glass tube 2 and the glass flange 5 The cavity between them is evacuated through the vacuum exhaust hole 6 to form a closed vacuum cavity 7 to form a heat absorber; the interlayer between the heat absorbing tube glass 2 and the insulating glass tube 3 constitutes a heated channel 8 of the thermal medium ( double as a thermal medium outflow channel), the interlayer between the insulating glass tube 3 and the inner glass ...

Embodiment 2

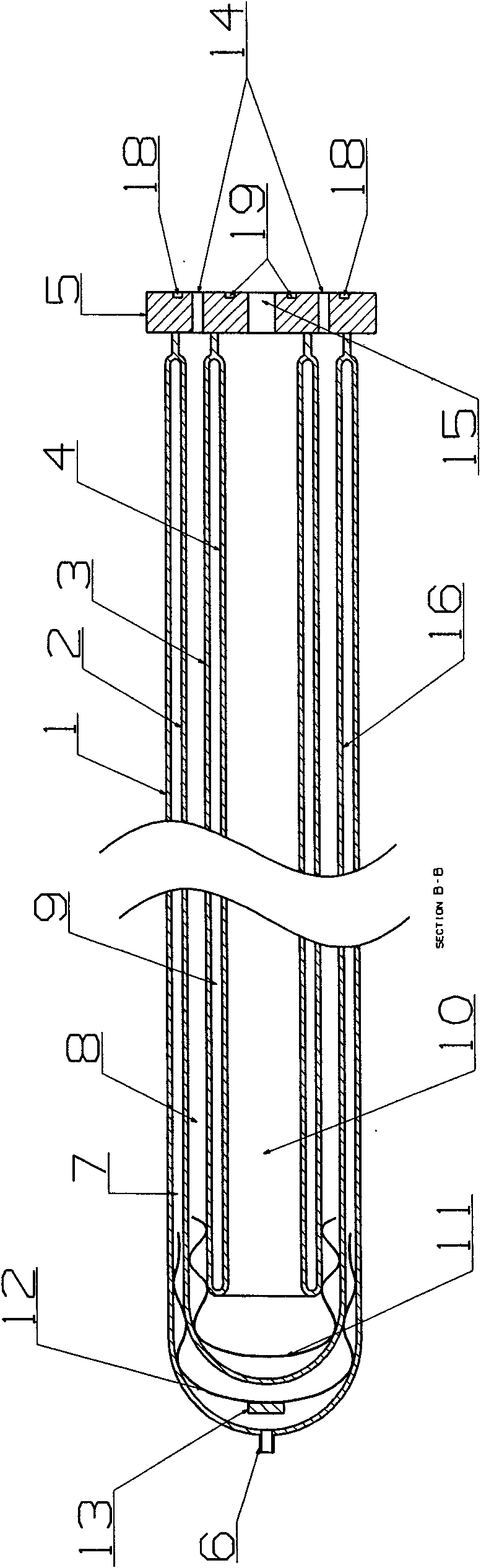

[0039] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0040] The shapes of the outlet 14 and the inlet 15 are flat.

[0041] An annular groove 18 for fitting a sealing gasket is provided between the outlet 14 and the inlet 15 , and an annular groove 19 for fitting a sealing gasket is arranged on the periphery of the outlet 14 .

[0042] On the outer side wall of the glass flange 5 there is no collar 17 for assembly.

[0043] The fusion sealing structure of the glass tube group and the glass flange is as follows: image 3 shown.

Embodiment 3

[0045] The structure of embodiment 3 is basically the same as embodiment 1, the difference is:

[0046] Two symmetrical notches 20 are arranged on the circular side of the glass flange 5, the notches 20 are convenient for the installation and replacement of the single tube in the all-glass double-channel vacuum tube heat collector, and the all-glass double-channel vacuum tube can be disassembled without order and can be installed. First remove the broken all-glass dual vacuum tube, then install the new tube.

[0047] The two ends of the heat-insulating glass layer 3 are fused to the inner glass tube 4 with a smaller diameter after necking, so that the thermal working medium in the glass inner tube is reduced, which is beneficial to improving the light-to-heat conversion efficiency of solar energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com