Suspension structure of pendent tube used for S-shaped tube panel

A suspension structure and suspension pipe technology, which is applied in the boiler support/positioning device and other directions, can solve the problems of difficulty in fine processing of zigzag brackets 3, easy to leave hidden dangers, difficult installation and other problems, and achieve convenient processing and installation. The effect of preventing the tube from going out of line and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

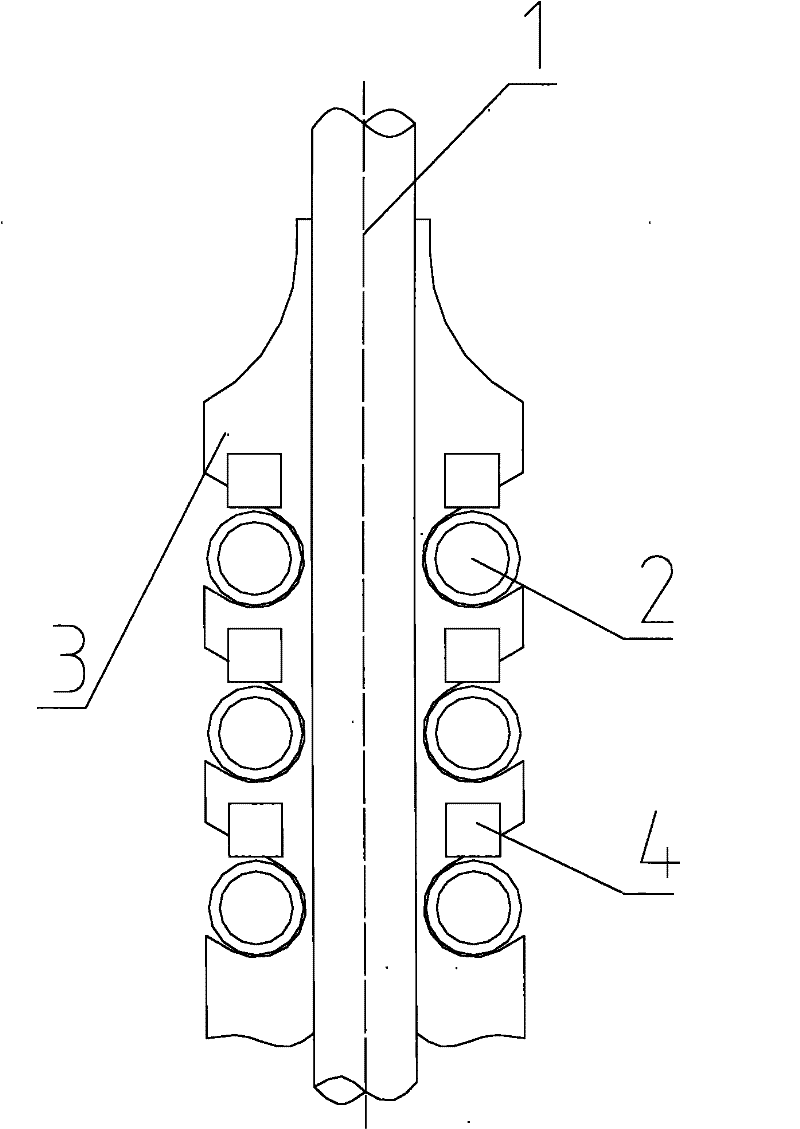

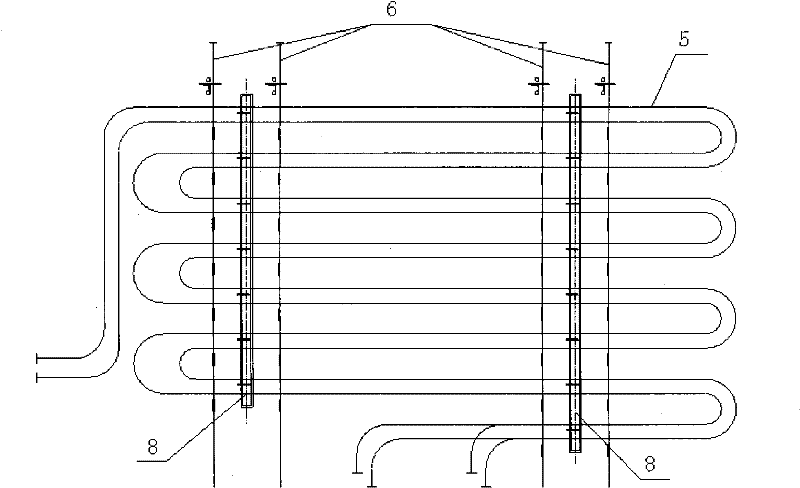

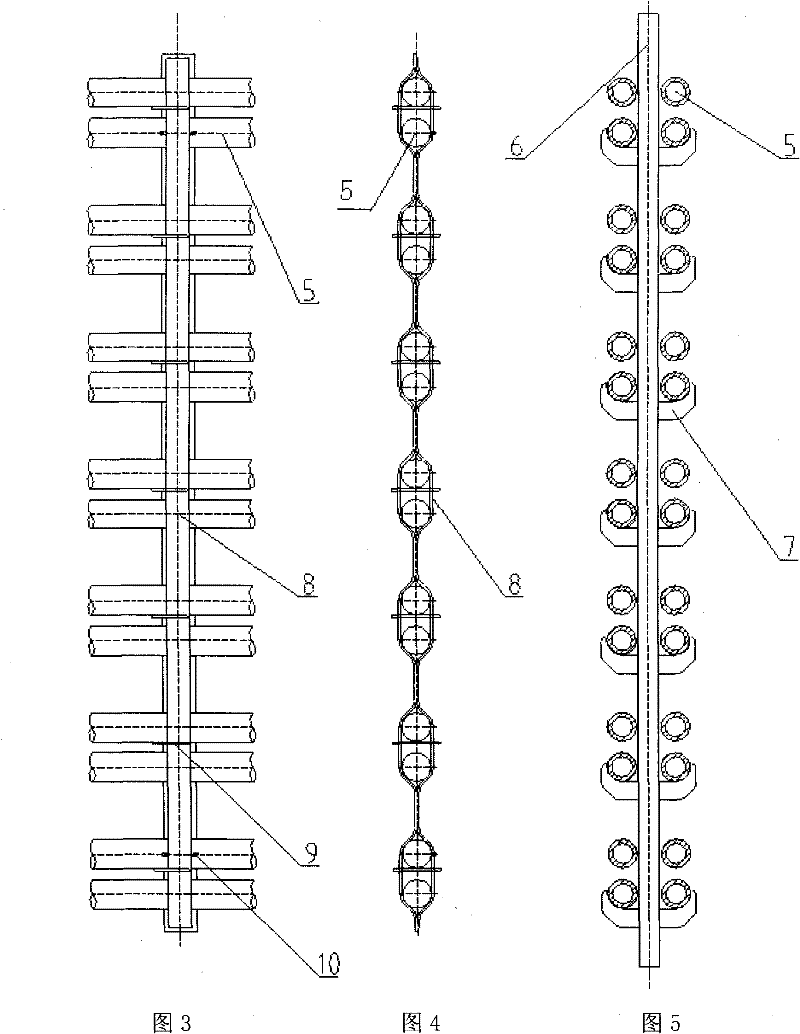

[0022] The invention provides a suspension pipe suspension structure for a serpentine tube panel, which is realized in the form of a suspension pipe and a pipe clamp. like image 3 and Figure 4 A schematic diagram of the pipe clamp section is shown, Figure 5 A schematic diagram of the suspension pipe section. Combine the following Figure 2 to Figure 5 To illustrate the present invention, it includes two pipe clamps 8 that are fastened on the tube panel 5. The widths of the two pipe clamps 8 are different to facilitate welding, and a steel plate 9 is inserted in the pipe clamp 8. A suspension pipe 6 is provided, and a supporting steel plate 7 for supporting the tube panel 5 is arranged horizontally on the suspension pipe 6 .

[0023] The suspension tube 6 only plays the role of transmitting the gravity of the tube panel 5, and the weight is transmitted through the supporting steel plate 7, while the tube clip 8 installed on the tube panel only plays the role of fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com