Composite type plastic pipe with wound netting wire and strengthened bell mouth and manufacturing process thereof

A composite type, plastic pipe technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of decreased tensile resistance of socket welds, difficulty in ensuring butt joint quality, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

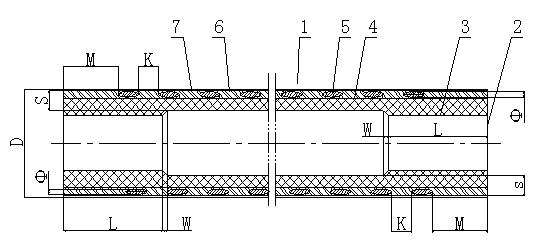

[0039] Referring to the accompanying drawings, a composite plastic pipe surrounded by steel wire and reinforced with a socket includes a pipe wall 1 and a socket 2. The pipe wall 1 with an inner diameter of L at the end of the socket 2 is a thickened reinforced wall 3, and the distance from the socket to The tube wall 1 with an outer diameter of M at the end of the mouth 2 is a steel wire reinforced wall 4, in order to make the two ends of the surrounding steel wire 5 and the socket 2 have better comprehensive and consistent performance, higher balance performance, and better docking Hot-melt performance, the ratio of the outer diameter length M to the inner diameter length L is set as 1:2, the wire reinforced wall 4 includes an adhesive layer 6, the adhesive layer 6 is equipped with a peripheral logo, a protective layer 7, and the wall thickness of the wire reinforced wall 4 S and the diameter φ of the steel wire 5 and the outer diameter D of the pipe wall 1 are set according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com