Symmetrical toggle rod pressure transmission mechanism

A technology of transmission mechanism and toggle lever, applied in the direction of presses, punching machines, transmission devices, etc., can solve the problems of low work efficiency, reduce motor driving torque, occupy high space, etc., achieve high positioning and repeated positioning accuracy, and improve work efficiency. Efficiency, the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

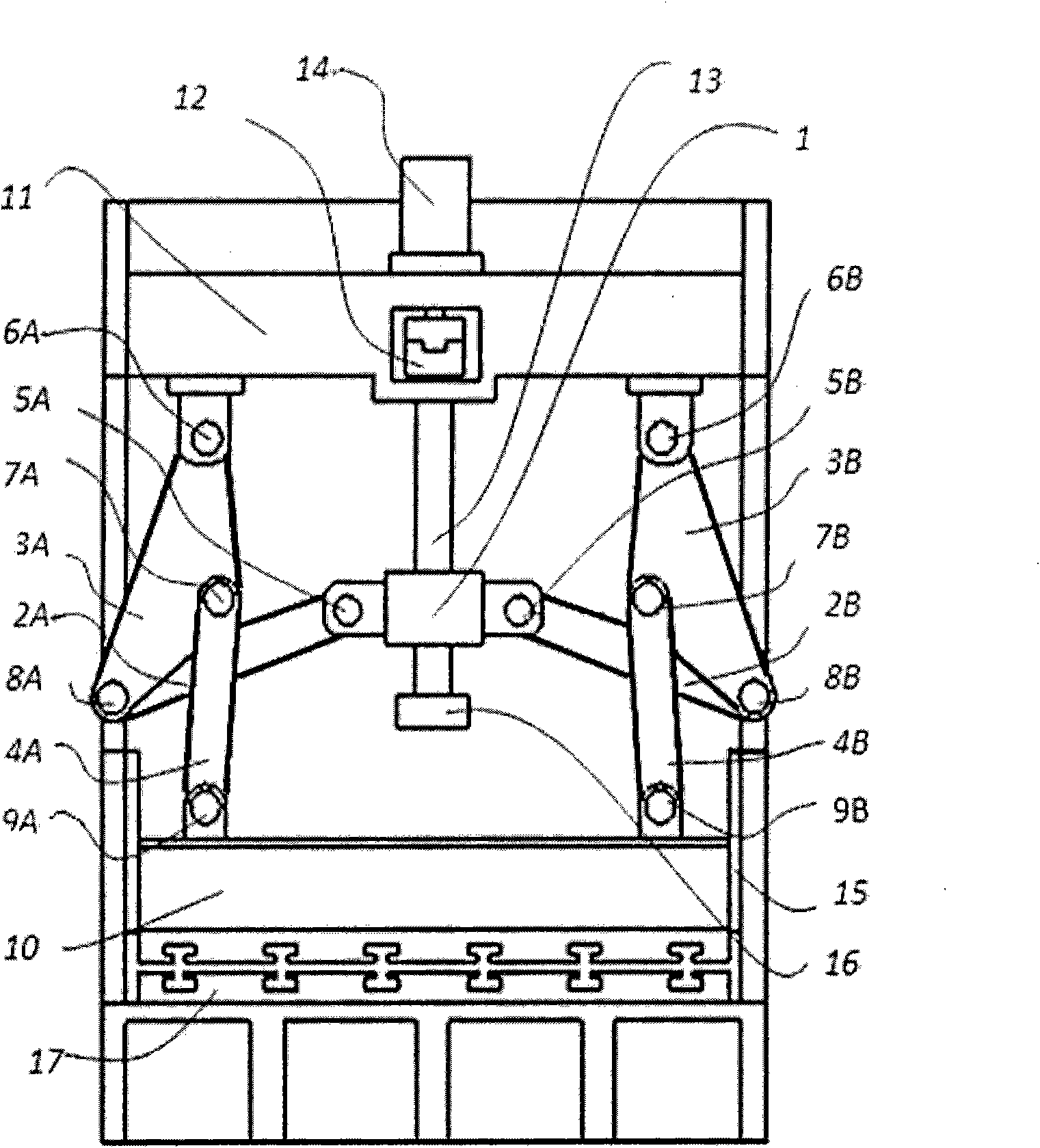

[0027] Such as figure 1 As shown, the first upper toggle plate 3A is fixed with the first upper beam hinge 6A, the first toggle hinge 7A and the first connecting hinge 8A, and the first upper toggle plate 3A is connected to the frame 11 through the first upper beam hinge 6A One end of the first lower toggle 4A is connected to the first upper toggle plate 3A through the first toggle hinge 7A, and the other end of the first lower toggle 4A is connected to the slider 10 through the first slider hinge 9A; the first intermediate link One end of 2A is connected to the first upper toggle plate 3A through the first connecting hinge 8A, and the other end of the first intermediate link 2A is connected to the driving block 1 through the first driving hinge 5A.

[0028] Symmetrically, the second upper toggle plate 3B is fixed with a second upper beam hinge 6B, a second toggle hinge 7B and a second connecting hinge 8B, and the second upper toggle plate 3B is connected to the frame 11 thr...

Embodiment 2

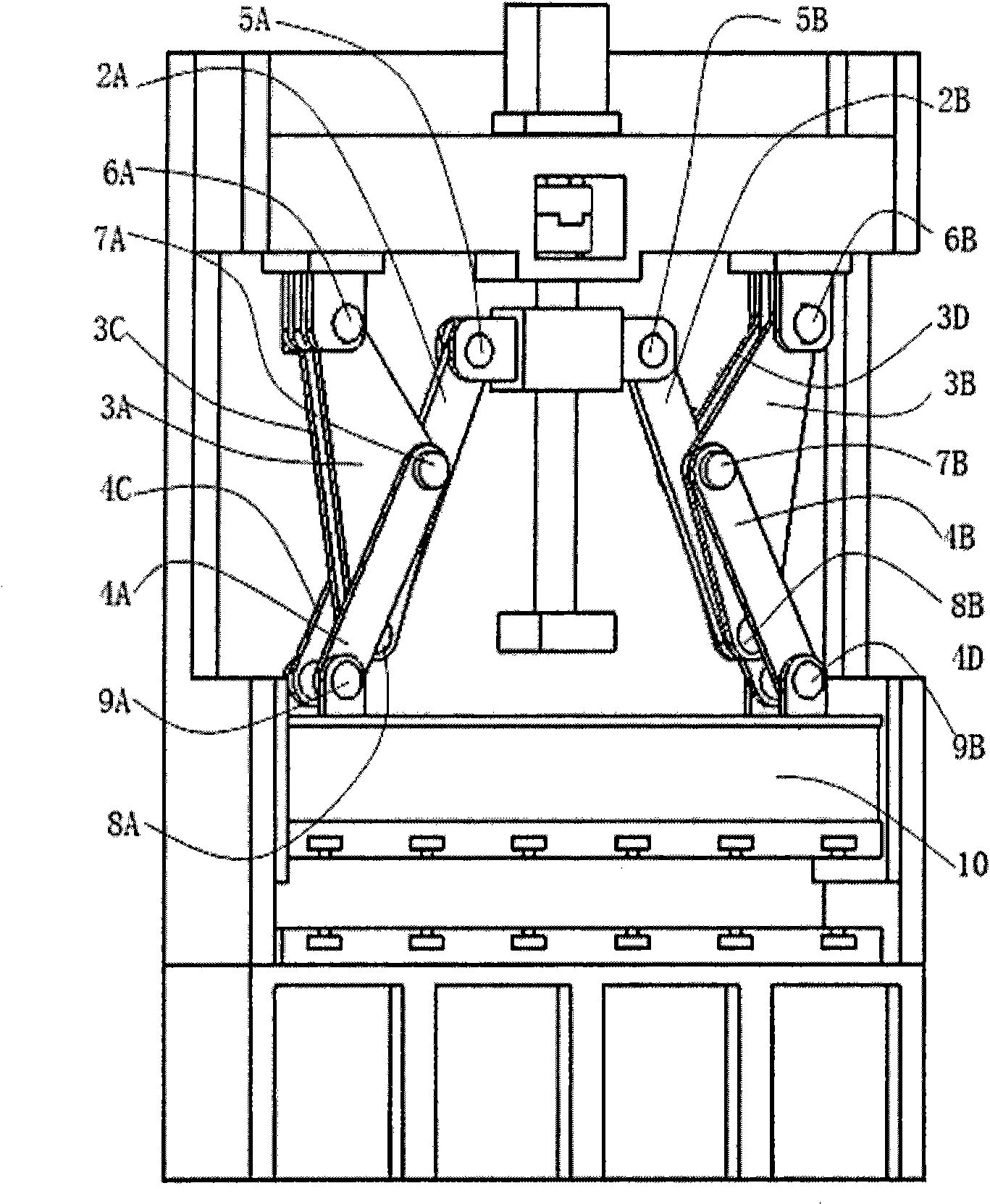

[0038] In order to ensure the force balance and stable operation of the mechanism, the respective numbers of the upper toggle plate, the lower toggle link and the intermediate link in the toggle mechanism can be arbitrarily determined according to actual needs without interference. In this embodiment, the single toggle mechanism has 2 upper toggle plates, 2 lower toggles, and 1 intermediate link.

[0039] Such as figure 2As shown, the third upper toggle 3C, the third lower toggle 4C, the fourth upper toggle 3D, and the fourth lower toggle 4D are added to the mechanism respectively with the first upper toggle 3A, the first lower toggle 4A, The second upper toggle plate 3B and the second lower toggle lever 4B form a group corresponding to the front and rear. Specifically, the arrangement is as follows: the first intermediate link 2A is hinged with the first upper toggle plate 3A and the third upper toggle plate 3C through the first connecting hinge 8A, and the third lower to...

Embodiment 3

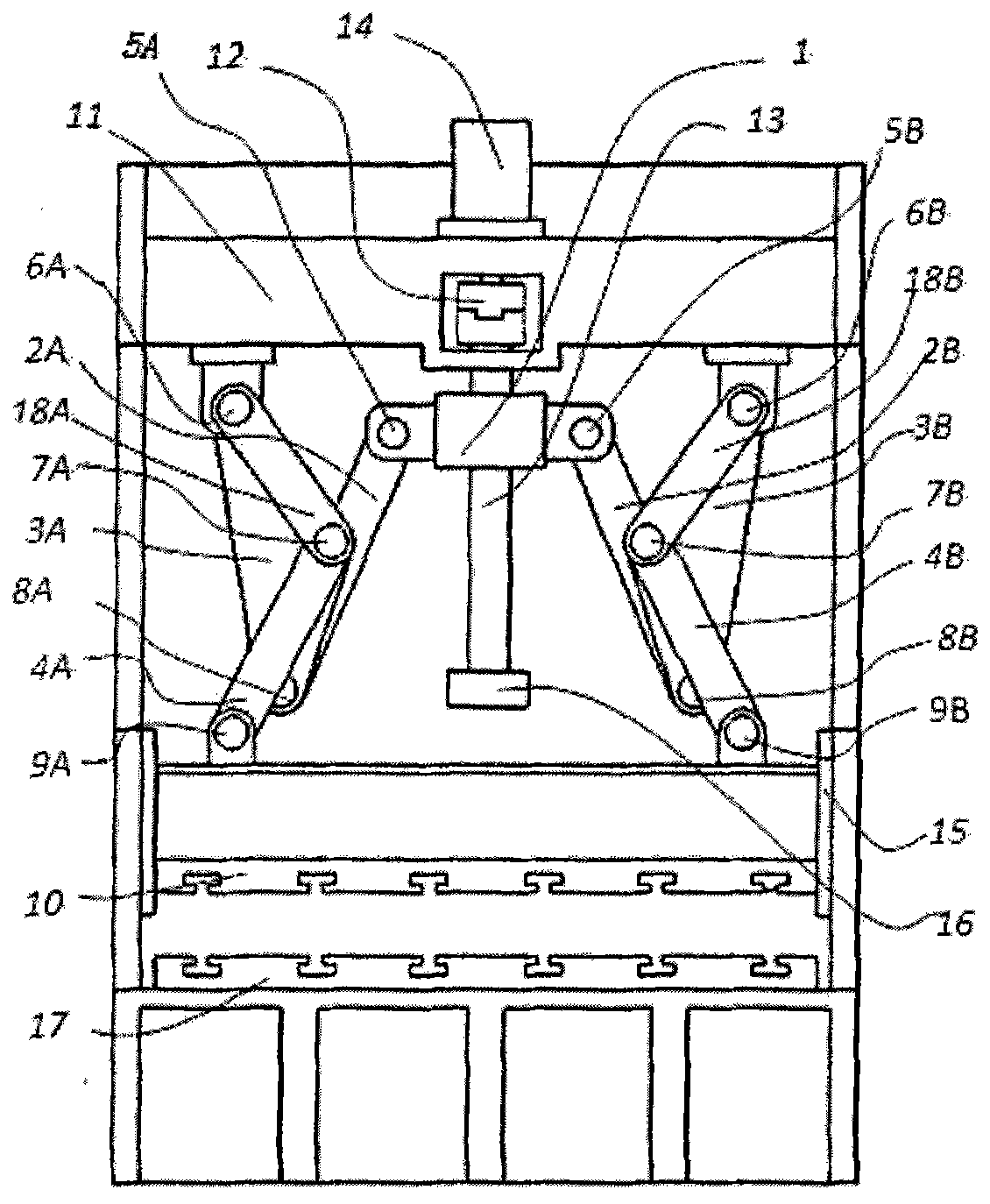

[0042] Such as image 3 As shown, in this embodiment, in order to have better mechanical properties of the mechanism, the first auxiliary upper bracket 18A, the second auxiliary upper bracket 18B, and the third auxiliary upper bracket 18C are added on the basis of the second embodiment. The fourth auxiliary upper toggle plate 18D is specifically arranged as follows: the first auxiliary upper toggle plate 18A and the second auxiliary upper toggle plate 18B are respectively added on the front side of the first lower toggle lever 4A and the second lower toggle lever 4B, A third auxiliary upper toggle plate 18C and a fourth auxiliary upper toggle plate 18D (not shown in this figure) are respectively added to the rear side of the lower toggle link 4C and the fourth lower toggle link 4D, and one end of the first auxiliary upper toggle plate 18A The first upper beam hinge 6A is hinged to the frame 11, the other end is hinged to the first lower toggle 4A through the first toggle hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com