Intelligent injection allocation testing device of water injection well

A technology for testing devices and water injection wells, applied in measurement, wellbore/well components, production fluids, etc., can solve problems such as increased testing workload, increased testing workload, and complicated situations, so as to avoid production testing and save conventional production The effect of testing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

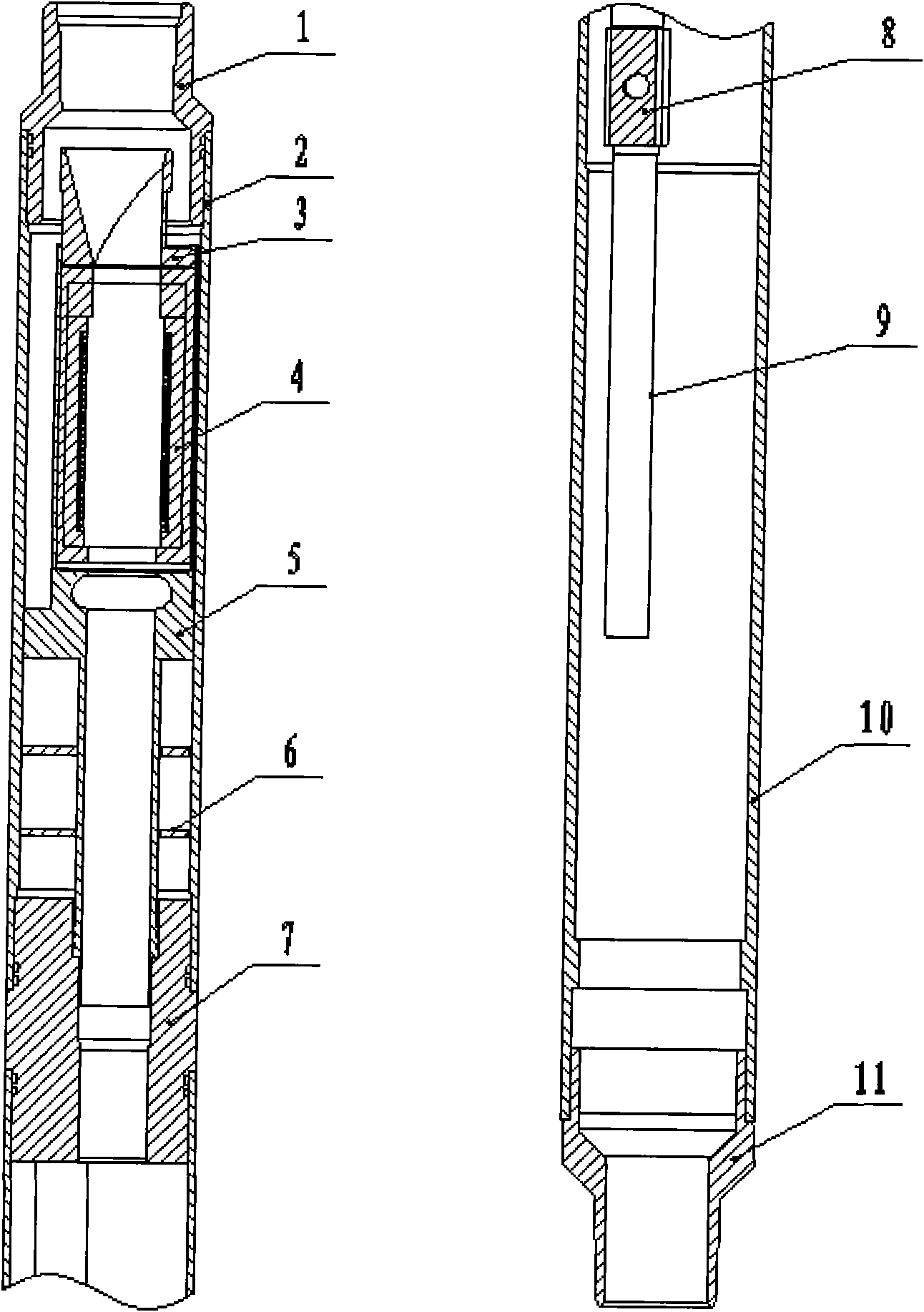

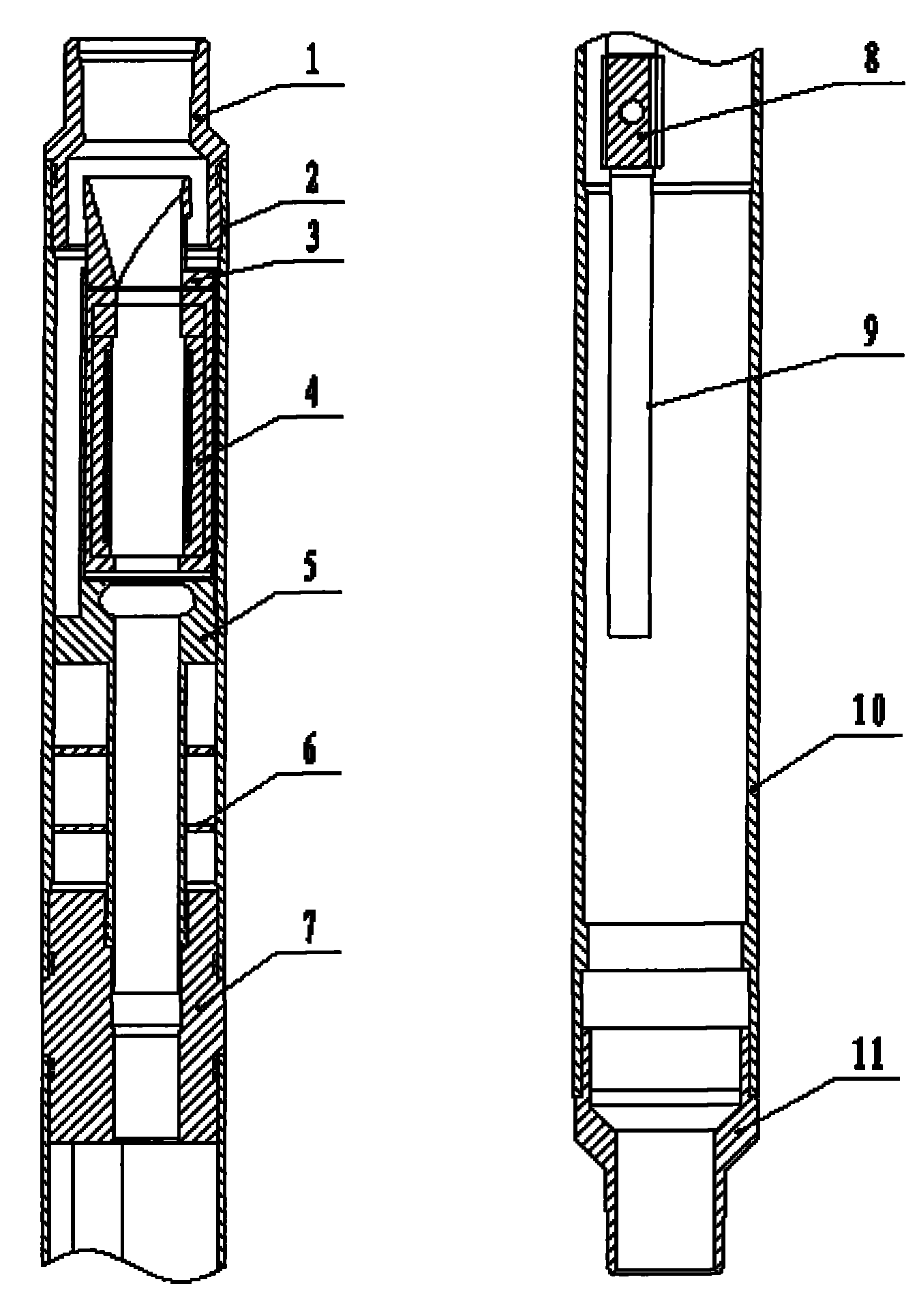

[0009] The present invention will be further described below in conjunction with the accompanying drawings: the intelligent water distribution device for water injection wells consists of an upper joint 1, an upper connecting sleeve 2, a guide body 3, a non-contact power conversion system 4, a central tube 5, a control circuit board 6, a main body 7, and a guide body. The fluid 8, the flow control valve 9, the lower connecting sleeve 10 and the lower joint 11, wherein the upper joint 1 and the upper connecting sleeve 2 are connected by threads, and the guide body 3 and the central pipe 5 are inserted into the upper connecting sleeve 2 after being connected by positioning. The upper connecting sleeve 2 is connected by thread, the non-contact power conversion system 4 is connected to the central tube 5 by positioning, the control circuit board 6 is connected to the central tube 5 by positioning, the upper end of the main body 7 is connected to the upper connecting sleeve 2 by thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com