Synthesis method of platy-ZnSe fluorescent nano monocrystal

A technique of fluorescent nano-synthesis method, which is applied in the field of synthesis of nano-materials, can solve the problems of long photodegradation time, preparation of flaky ZnSe nano-single crystals, difficulty in washing nano-crystals, etc., to achieve toxicity and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

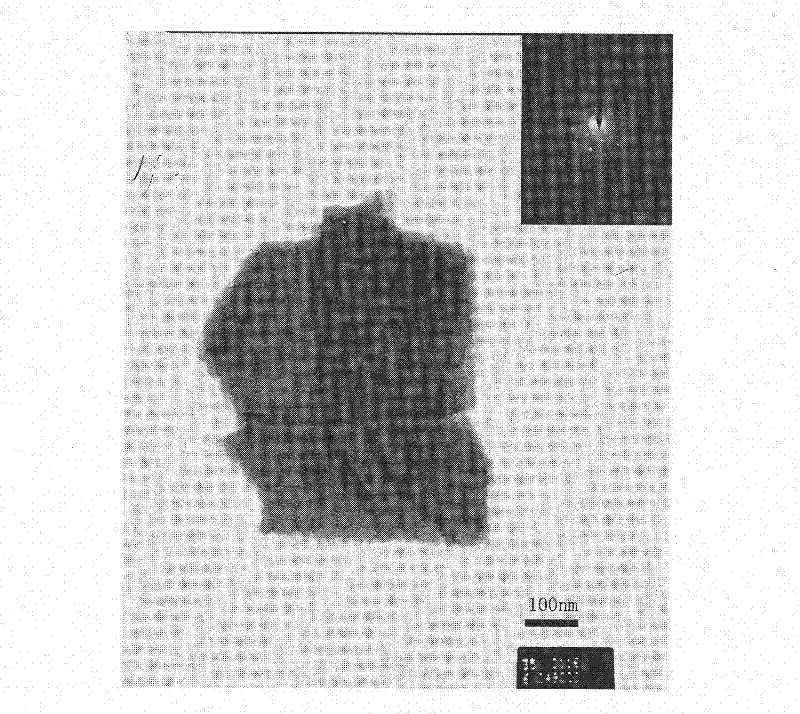

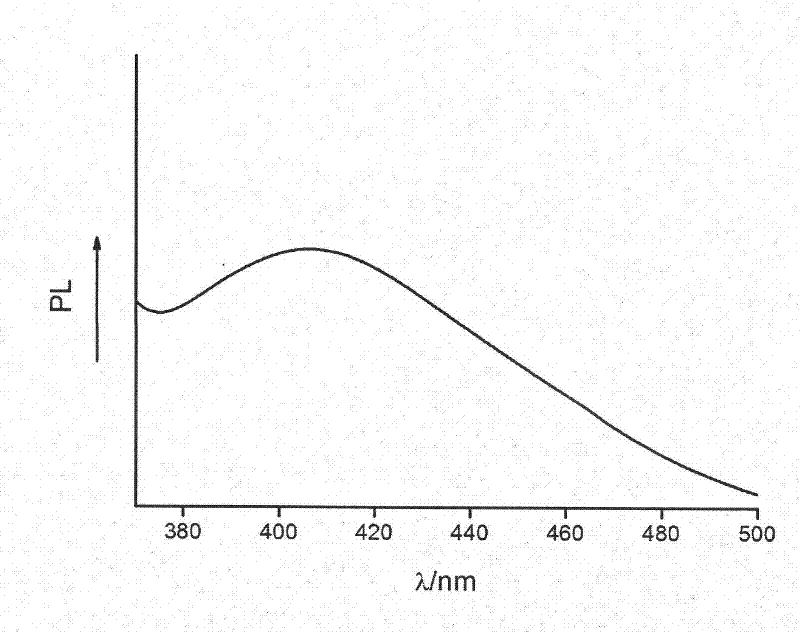

[0047] Synthesis of flaky ZnSe fluorescent nano single crystals:

[0048] 1. First, heat 0.6 mmol of selenium and 1 g of trioctylphosphine in an oil bath at 40° C. under the protection of nitrogen, and stir for one hour to obtain a selenium precursor.

[0049] 2. Stir and mix 2 g of octadecene, 0.085 mmol of zinc stearate, and 0.4 mmol of octadecylamine under the protection of nitrogen to obtain a zinc precursor. The zinc precursor was "activated" by stirring at 50°C for 3 hours.

[0050] 3. Add 8 mmol of octadecyl mercaptan to the zinc precursor under nitrogen protection, and then stir at 50° C. for 1 hour to perform “template” treatment.

[0051] 4. Continue to raise the temperature of the zinc precursor system to 305°C under the protection of nitrogen, and quickly inject the selenium precursor into the zinc precursor while stirring. At this time, the temperature of the reaction system drops to 275°C, and the nanocrystals begin to grow, and the reaction start the timer.

...

Embodiment 2

[0055] 1. Firstly, 0.6 mmol of selenium and 1 g of trioctylphosphine were heated at 40° C. under the protection of argon and ultrasonicated for half an hour to obtain a selenium precursor.

[0056] 2. Stir and mix 2 g of octadecene, 0.1 mmol of zinc stearate, and 0.8 mmol of octadecylamine under the protection of argon to obtain a zinc precursor. The zinc precursor was "activated" by ultrasonication at 70°C for 1 hour.

[0057] 3. Add 8 mmol of octadecyl mercaptan to the zinc precursor under nitrogen protection, and then stir at 65° C. for 0.5 hour to perform “template” treatment.

[0058] 4. Continue to raise the temperature of the zinc precursor system to 305°C under the protection of argon, and quickly inject the selenium precursor into the zinc precursor while stirring. At this time, the temperature of the reaction system drops to 275°C, and the nanocrystals begin to grow. The reaction starts timing.

[0059] 5. After the nanocrystals start to grow, when the reaction tim...

Embodiment 3

[0062] 1. First, 0.6 mmol of selenium and 1 g of trioctylphosphine were heated at 40° C. under nitrogen protection and ultrasonicated for half an hour to obtain a selenium precursor.

[0063] 2. Fully grind the zinc precursor composed of 2 g of octadecene, 0.085 mmol of zinc stearate, and 0.8 mmol of hexadecylamine at 25° C. for 3 hours to realize its “activation” treatment.

[0064] 3. Add 4 mmol of octadecyl mercaptan to the zinc precursor under nitrogen protection, and then stir at 70° C. for 1 hour to perform “template” treatment.

[0065] 4. Under the protection of nitrogen, raise the temperature of the zinc precursor system to 315°C, quickly inject the selenium precursor into the zinc precursor while stirring, at this time, the temperature of the reaction system drops to 290°C, the nanocrystals begin to grow, and the reaction start the timer.

[0066] 5. After the nanocrystals start to grow, when the reaction time reaches 1 hour and 30 minutes, stop heating and end the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com