Water treatment system with bidirectional cleaning function

A water treatment system and two-way cleaning technology, applied in the field of water treatment, can solve the problems of clogging the flow channel, the particles cannot be discharged from the inner cavity of the membrane, and the pollution of the inner membrane cavity, etc. The effect of high fluid velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

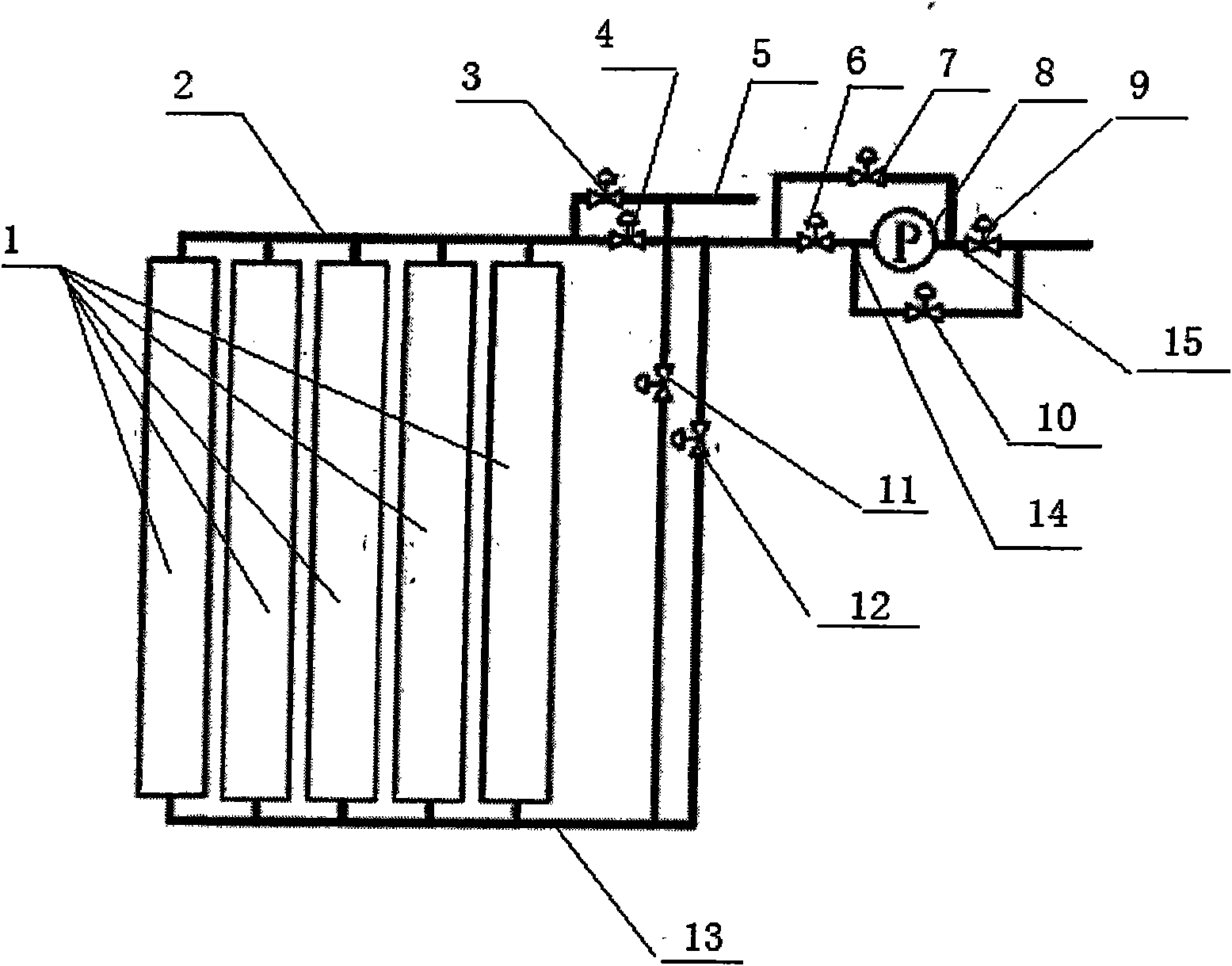

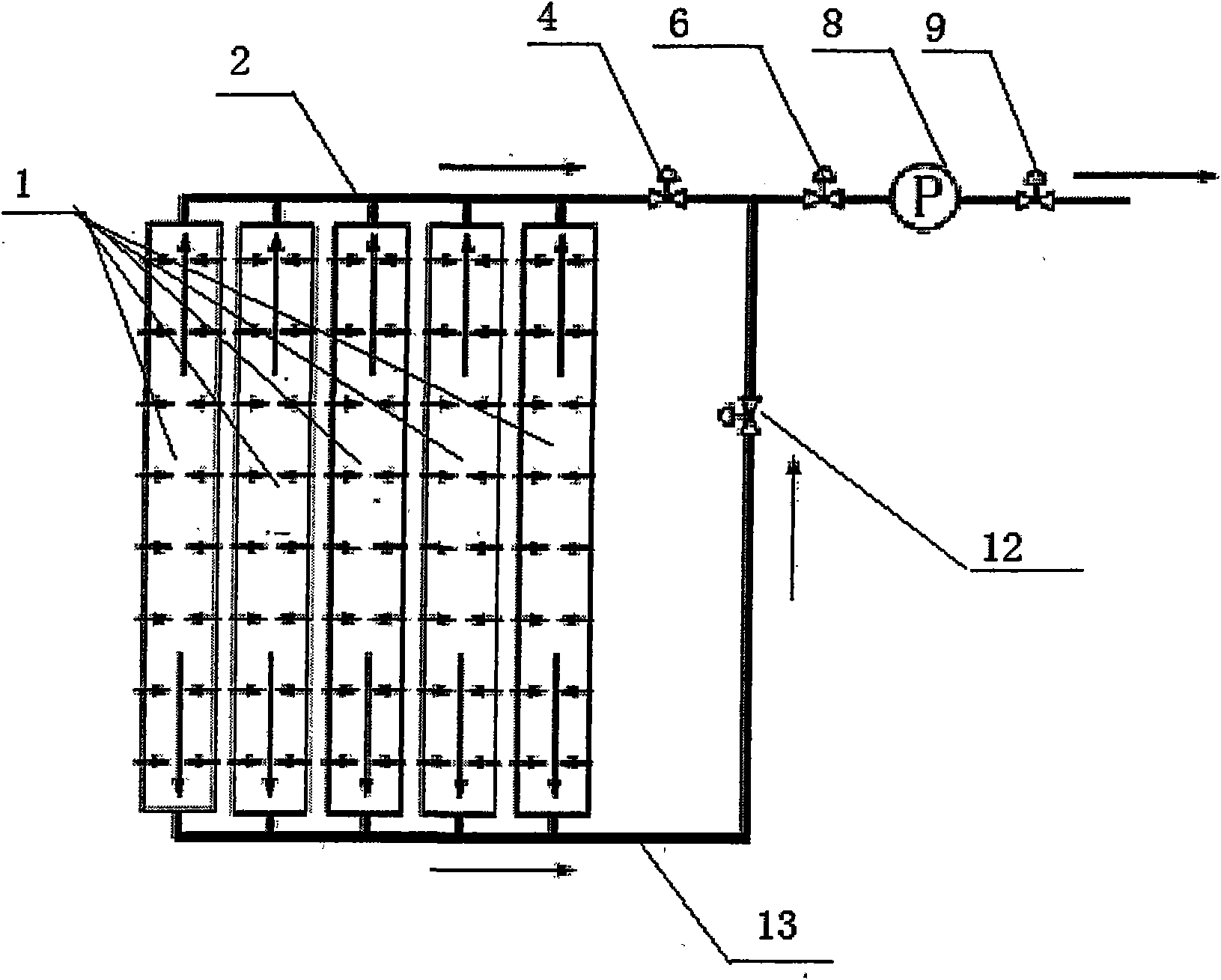

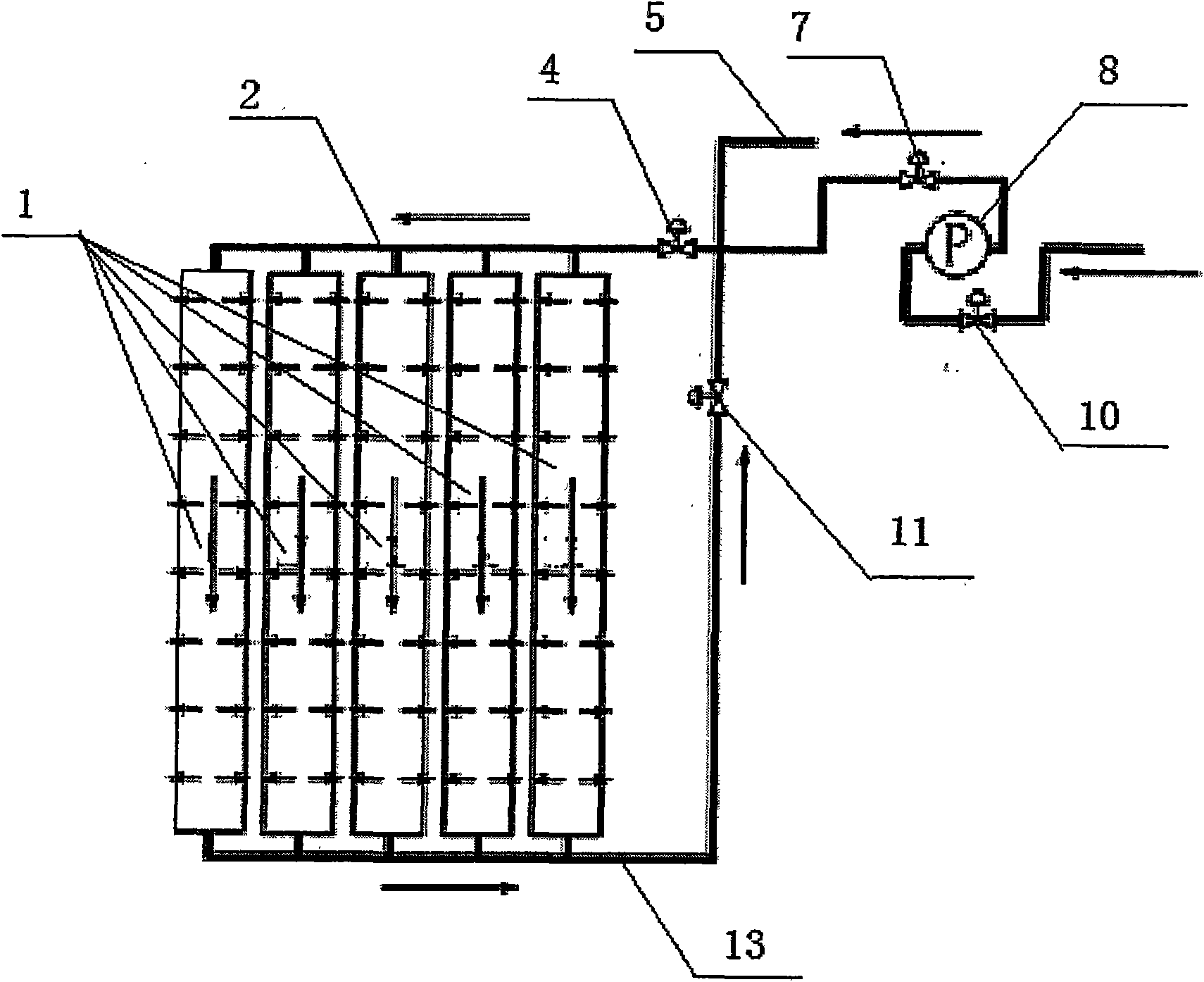

[0016] The schematic diagram of the water treatment system with two-way cleaning function of the present invention is as figure 1 As shown, it includes multiple sets of double-ended water outlet external pressure membrane modules 1, the upper water outlets of each double-ended water outlet outer pressure membrane module are respectively connected to the upper end filtrate collection pipe 2, and the lower end water outlets are respectively connected to the lower end filtrate collection pipe 13 The upper filtrate collection pipeline 2 is connected to the first control valve 4 and the second control valve 3 respectively, and the lower filtrate collection pipeline 13 is connected to the third control valve 12 and the fourth control valve 11 respectively. The first control valve 4 and the third control valve 12 are connected in parallel to the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com