Novel groove drum motor

A new type of tank drum technology, applied to electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve problems such as tank drum motor vibration, and achieve stable operation, low temperature rise, and fewer failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

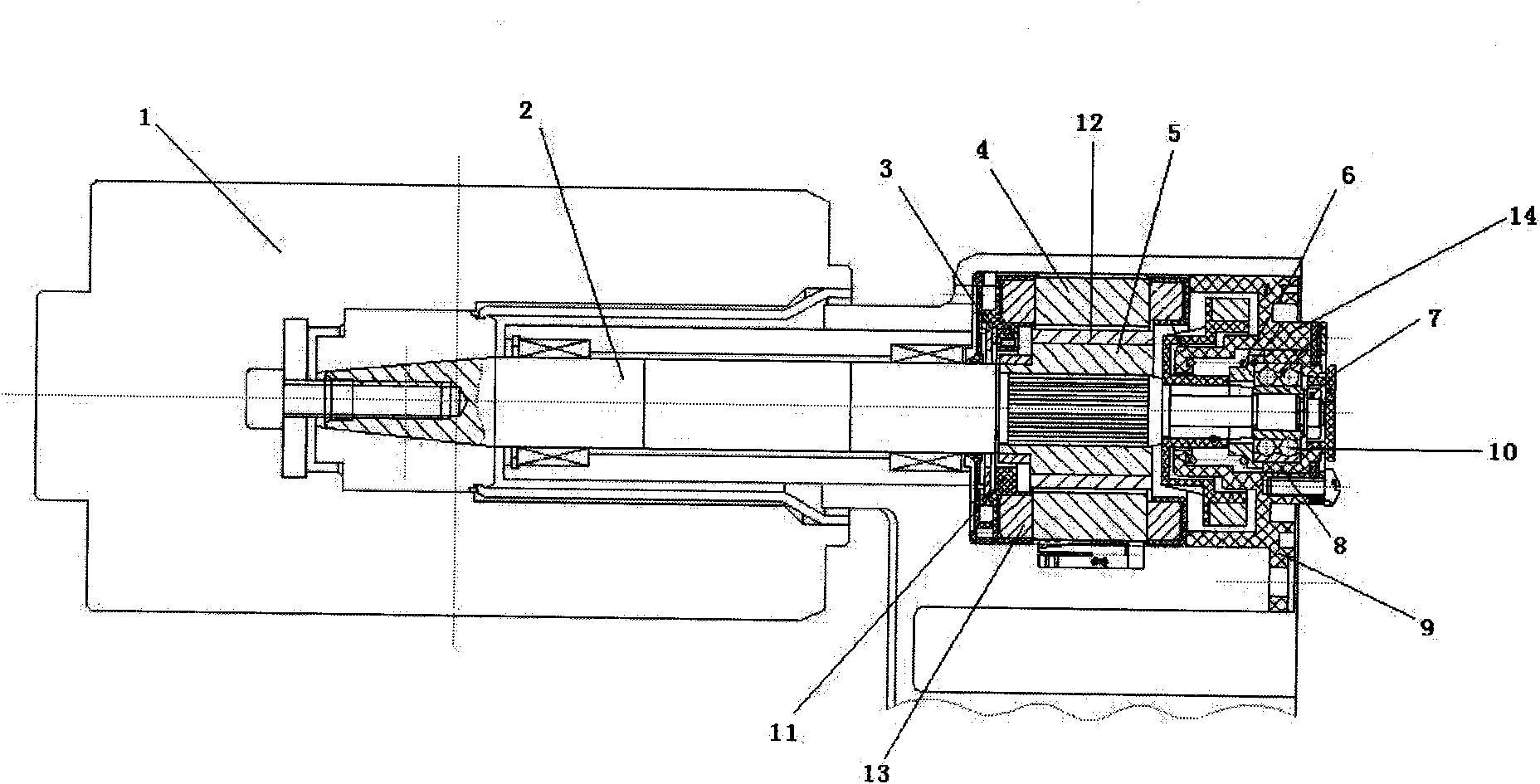

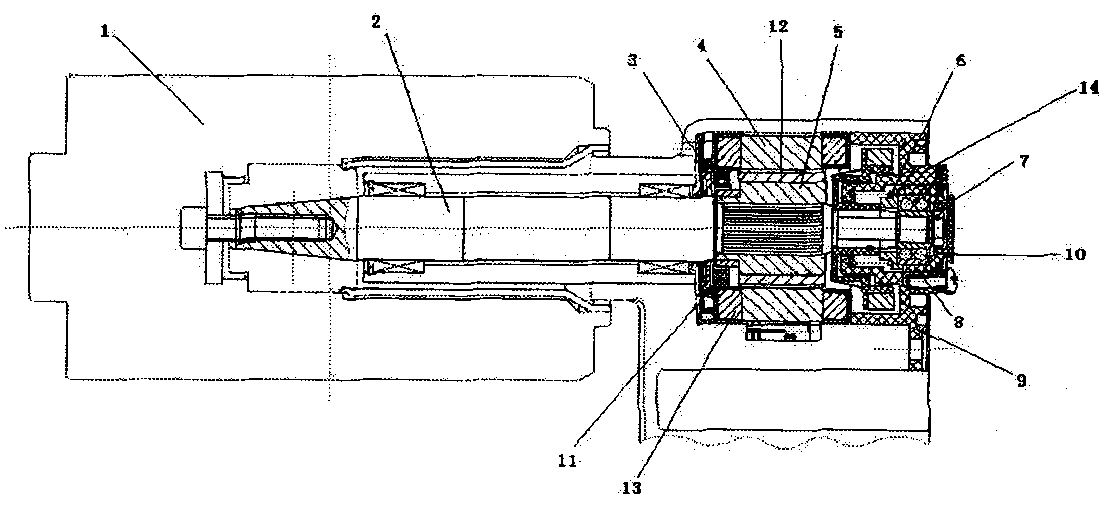

[0007] The invention is a novel slotted drum motor. The number of magnetic steels 5 on the rotor of the high-speed slotted drum motor is thirteen, and the arrangement is uniformly distributed along the circumference with the iron core 2 as the center. Each magnetic steel has N and S poles at the same time, so that there is no gap and weak magnetic field during the high-speed operation of the rotor. The present invention includes a stator, the stator is composed of a cylindrical coil 13 embedded in the inner ring of the silicon steel sheet 4; the iron core 2, the main magnetic steel 5, the stainless steel sheath 12, and the bracket 14 are combined together, and are supported by the bearing 10 on the seat body. A cantilever rotor is formed in the hole, and the rear cover 9 is closed on the rotor by screws, and then the end face is blocked by the end cover 7. A circuit board support is installed on the rear cover 9, and the positioning detection Hall sensor 11 and the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com