Probe device

A technology of detectors and mounting tables, which is applied in the direction of measuring devices, instruments, and parts of electrical measuring instruments, etc., which can solve unsatisfactory large-scale devices, longer standby time of inspection parts, and lower detector test processing capabilities, etc. problem, achieve the effect of shortening the standby time and suppressing the reduction of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

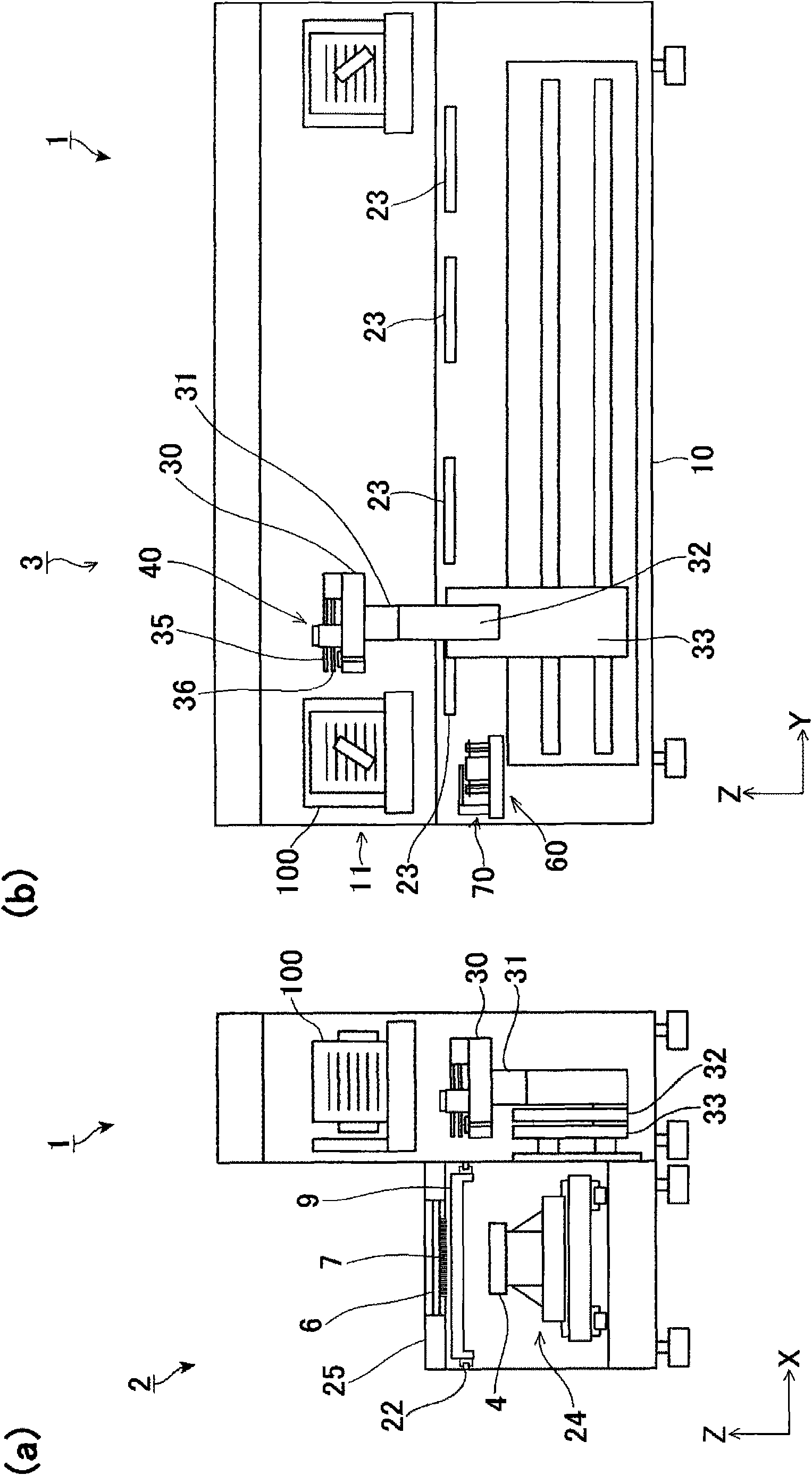

[0080] refer to Figure 13 to Figure 16 A detector device according to a second embodiment of the present invention will be described. The probe device of the second embodiment is the same as that of the first embodiment except for the structure of the substrate holding device 170 , and therefore, the same or equivalent parts as those of the first embodiment will be described with the same reference numerals. In the first embodiment, the substrate holding device 70 only suction-holds the wafer W. However, in the substrate holding device 170 of the present embodiment, pre-alignment of the held wafer W can be performed as necessary.

[0081] In this embodiment, if Figure 13 , Figure 14 As shown, an installation portion 168 is provided on the upper surface of the base 61 of the substrate storage portion 60 . The setting portion 168 has a flat plate 169 forming a horizontal plane in an area above the substrate storage portion 60 , and the substrate holding device 170 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com