Automatic on-line detecting device for welding lines of mast of wind driven generator

A detection device, fan tower technology, applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve problems affecting inspection quality, potential safety hazards and low detection efficiency. , to achieve broad application prospects, improve efficiency and automation level, and achieve stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

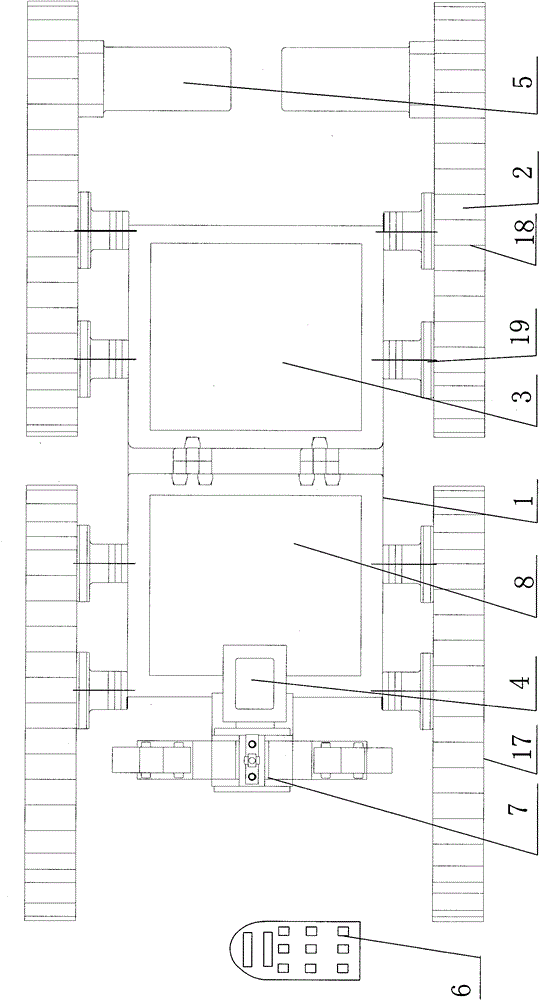

[0026] The automatic online inspection device for the welding seam of the wind turbine tower consists of: an underframe 1, with crawler wall climbers 2 installed on both sides of the underframe 1, the underframe 1 is equipped with an electric control box 3, the The electrical control box 3 is connected to the industrial camera 4, the motor 5, and the flaw detector 8. The electrical control box 3 is controlled by the remote control 6, and the flaw detector 8 is connected to the probe module 7 through a wire. The probe module 7 and the flaw detector The instrument 8 constitutes a phased array ultrasonic nondestructive testing system.

Embodiment 2

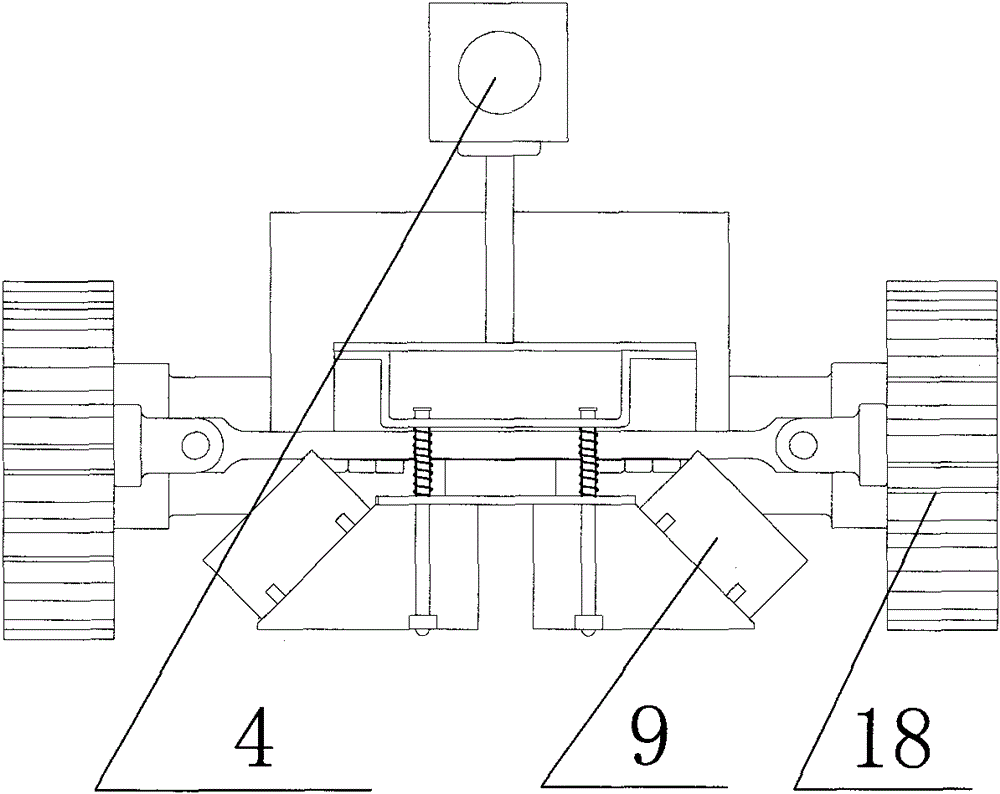

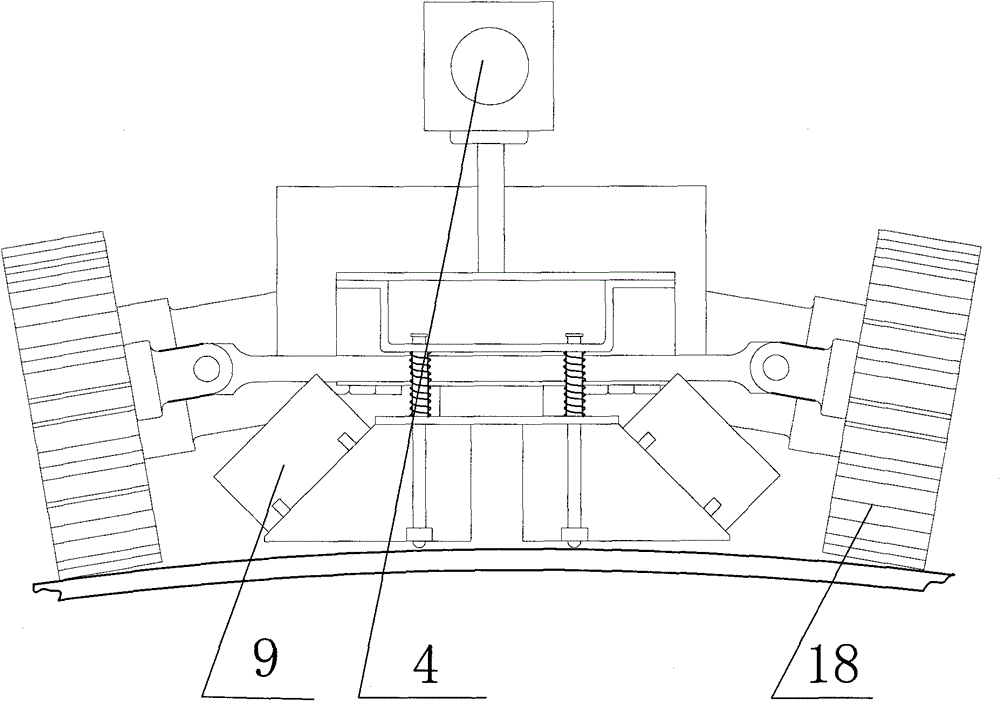

[0028] In the automatic online inspection device for welding seam of the wind turbine tower described in embodiment 1, the probe module 7 includes a probe 9, and the probe 9 is installed on a wedge 10, and the wedge 10 is connected to the middle plate 11 by screws On one side, the intermediate plate 11 is connected to the support plate 13 through a spring 12, a bracket 14 is installed on the support plate 13, and the other side of the intermediate plate 11 is connected to a universal ball 16 through a guide rod 15.

Embodiment 3

[0030] According to the automatic on-line inspection device for the welding seam of the wind turbine tower tube of the embodiment 1, the crawler wall climber 2 includes a crawler wheel 17 and a crawler 18 surrounding the crawler wheel; the crawler wall climber is a cross Symmetrical structure.

[0031] In the automatic online inspection device for welding seam of the wind turbine tower, the industrial camera 4, the electrical control box 3, the probe module 7, and the flaw detector 8 are all installed on the base frame 1 and fixed with screws; the crawler wheel 17 and The underframes 1 are connected by hinges 19, the underframe is composed of two bottom plates, the two bottom plates are connected by a pin, and the crawler wheel and the crawler are a set.

[0032] According to the automatic online detection device for the welding seam of the wind turbine tower, the wall climber can carry out various operations by carrying different equipment and instruments;

[0033] (1) Inspection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com