Electrically-controlled pump nozzle for injecting fuel of diesel motor

A diesel engine, fuel injection technology, applied in the direction of fuel injection pump, engine control, fuel injection control, etc., can solve the problems of increasing leakage, reducing strength and rigidity, large volume of high-pressure pipeline, etc., to reduce harmful emissions, improve Fuel injection characteristics, improving the effect of in-cylinder combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

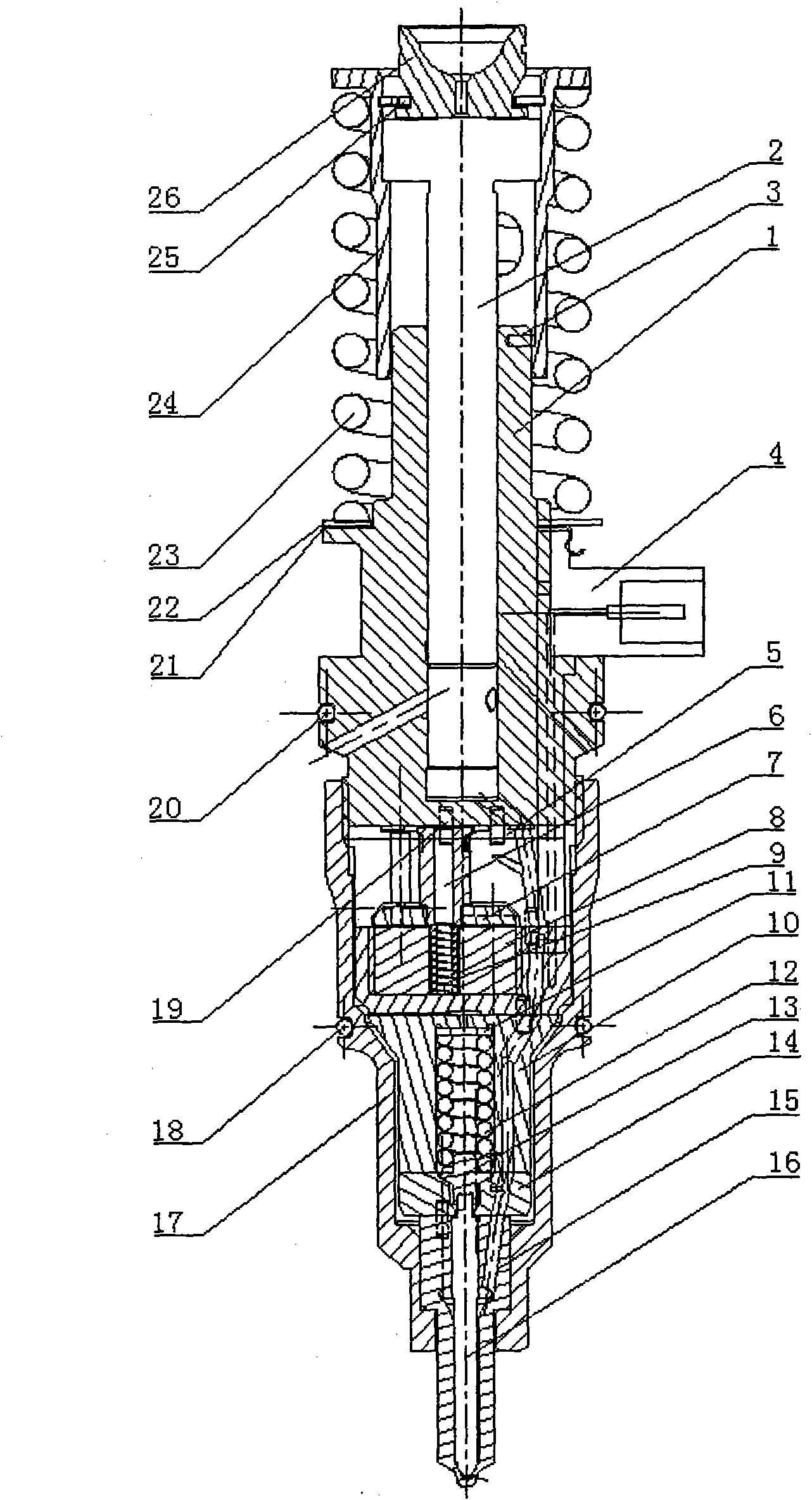

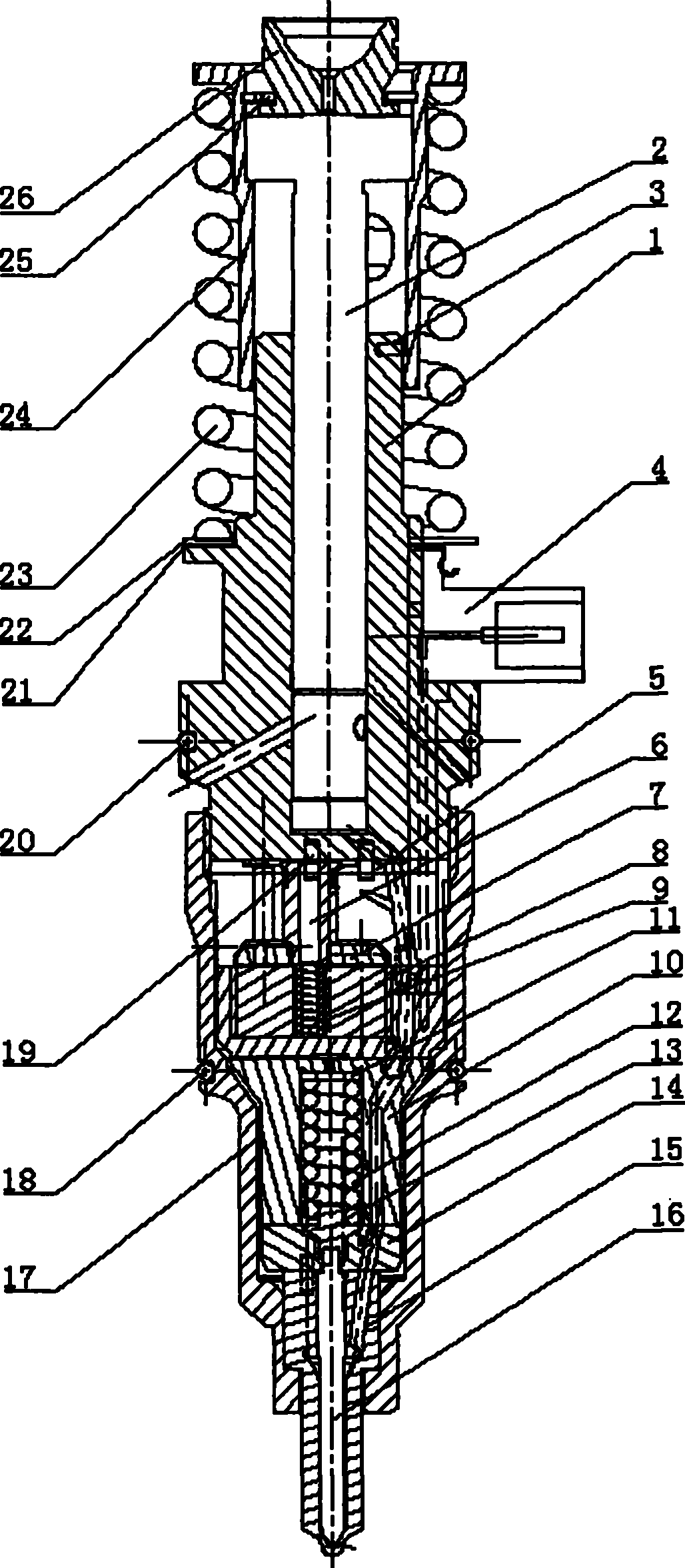

[0013] As shown in the figure, the diesel engine fuel injection electronically controlled pump nozzle includes a plunger coupling, a plunger spring, a plunger spring seat, a retaining ring, a rocker pad, a solenoid valve and a fuel injector.

[0014] The plunger pair includes: a pump body 1, a plunger 2 and a limit pin 3. The pump body 1 has a plunger hole, an oil inlet hole and an oil passage. The plunger hole and the lower end of the plunger form a fuel pressure chamber. Three oblique oil inlet holes are evenly distributed radially, starting from the pump nozzle and its upper sealing ring 18, the positioning pin 19 and the cylinder block to form an annular oil storage chamber, leading to the fuel pressure chamber in the pump body, and the oil passage at the bottom of the pressure chamber It communicates with the main oil passage of the control valve components below.

[0015] Solenoid valve is made up of control valve part, electromagnet 8, spool spring 9 and electric cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com