Yarn winding device and spinning machine

A technology of winding device and filament, which is used in transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., which can solve the problems of inability to form packages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

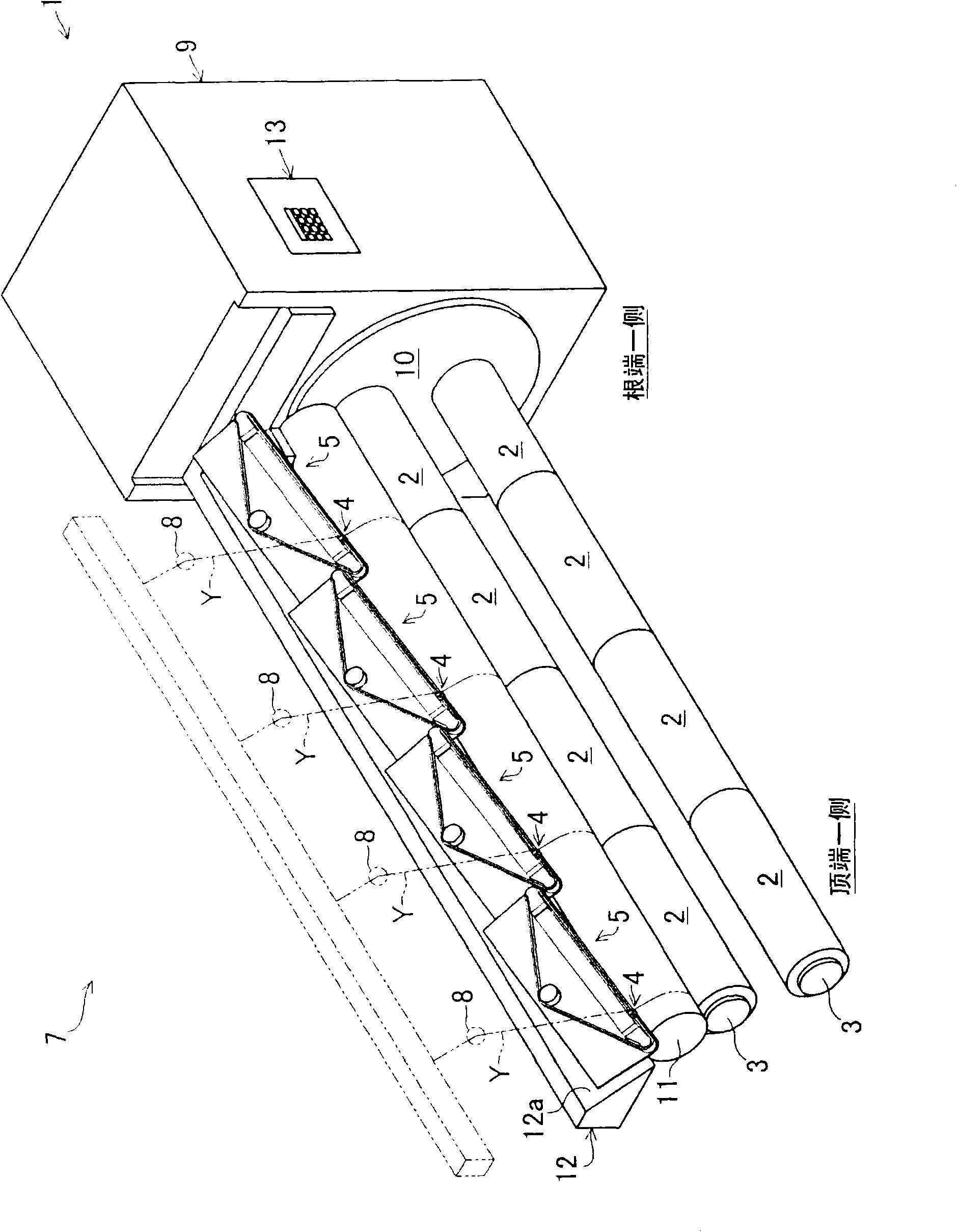

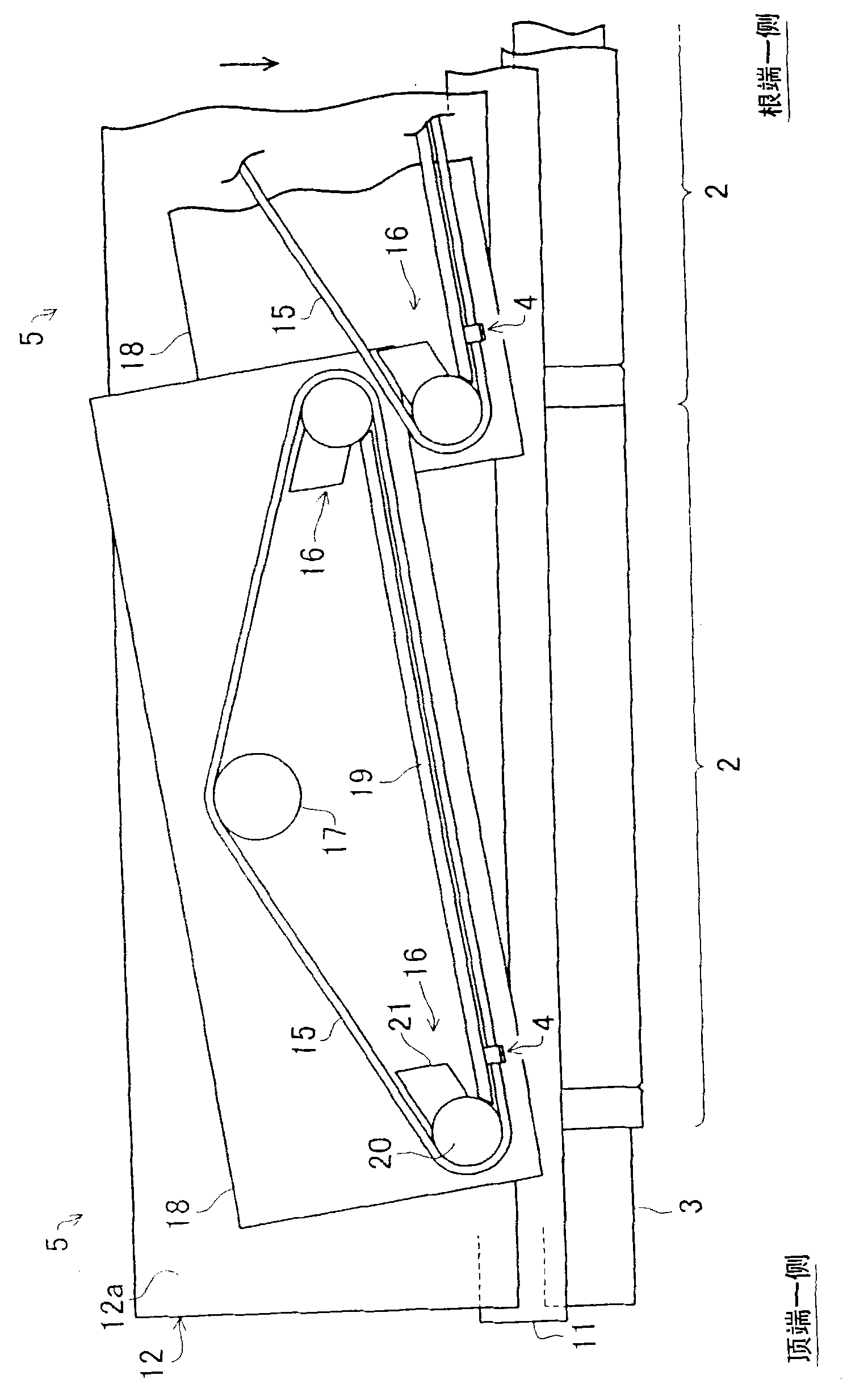

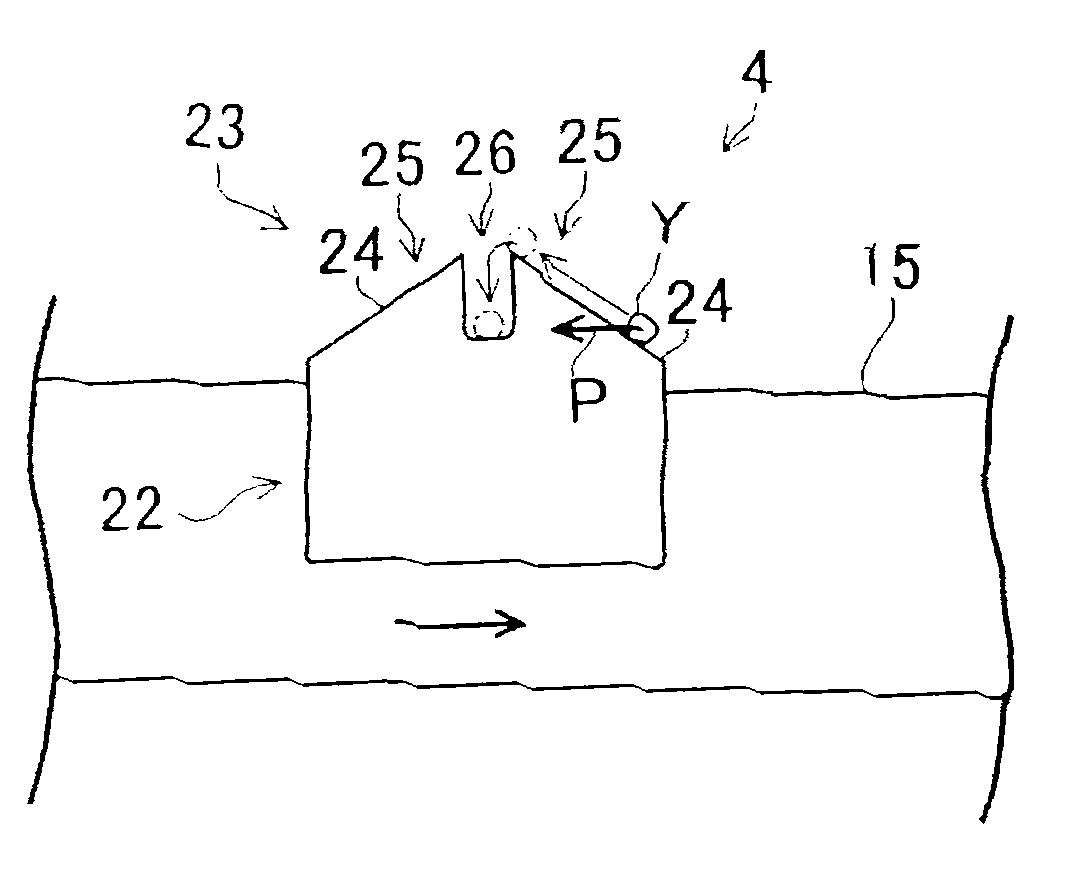

[0038] Refer below Figure 1-7 The first aspect of the present application will be described.

[0039] figure 1 It is a perspective view of the yarn winding device according to the first embodiment of the present invention. like figure 1 As shown, the yarn winding device 1 of this embodiment has a bobbin holder 3 and a plurality of (4 in this embodiment) traverse devices 5 as a main structure, and the bobbin holder 3 is rotated from one direction on the same axis. There are a plurality of (4 in this embodiment) winding bobbins 2 that are used to wind respectively provided multiple (4 in this embodiment) filaments Y that are arranged next to each other; the traverse device 5 has The yarn guide 4 capable of catching each of the above-mentioned yarns Y traverses each yarn Y with respect to each winding bobbin 2 by reciprocating the yarn guide 4 . In addition, each traverse device 5 has a structure in which the reciprocating range of each yarn guide 4 is shifted in the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com