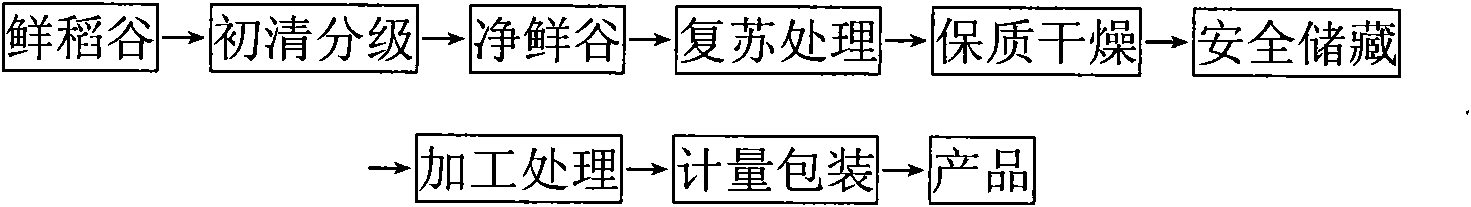

Method for processing active rice

A processing method and active technology, applied in the direction of grain degermination, grain treatment, grain milling, etc., can solve the problems of low germ content, high power consumption, and large water consumption in rice with retained germs, and achieve high mineral content. , Improve the processing yield and make full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Select fresh and wet paddy with moisture between 20% and 21% just harvested according to the existing conventional method.

[0029] (2) Cleaning and grading the fresh wet rice according to existing conventional methods to remove impurities and become clean fresh rice.

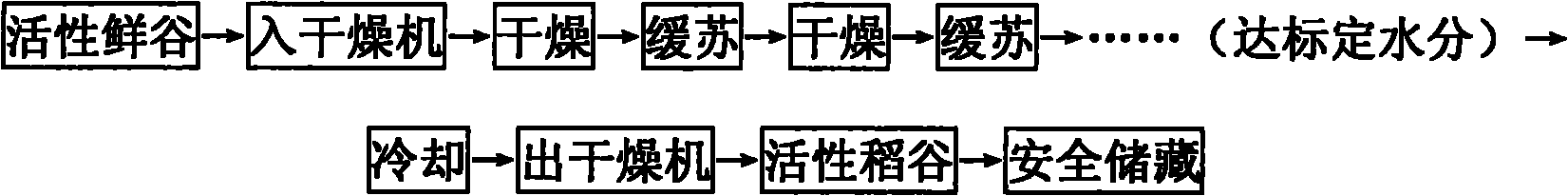

[0030] (3) Put the net fresh grain into a batch dryer with a capacity of 12 tons, and use hot and humid air at 45°C to 50°C and a relative humidity of 85% to 90% to heat up the grain in the machine. The clean and fresh grain circulates in the dryer and repeatedly obtains heat from the hot and humid air. The heating time is 1.5h, and the temperature of the fresh grain is raised to 25°C.

[0031] (4) Put fresh grains with a temperature of 25°C and a moisture content of about 20.5% into a one-storey warehouse with an air duct to carry out the recovery process, and the recovery time is 48 hours. When recovering, it is necessary to send fresh air into the warehouse, and the air supply volume per ton of ...

Embodiment 2

[0037] (1) According to the conventional method, the stored active paddy with moisture content of 14% is transported to the processing workshop from the warehouse.

[0038] (2) Cleaning, grading, husking, and paddy separation of the active rice according to conventional methods to obtain active brown rice.

[0039] (3) Put the activated brown rice into the rice mill hopper. The adjusted brown rice is firstly subjected to tempering treatment, and the weight percentage of the surface water of the brown rice is controlled between 14.5% and 16.5%, and the weight percentage of the internal water is between 13.% and 15%. The whitening treatment process is carried out again, and the processing flow of 8 emery roller rice mills and 1 iron roller rice mill in series is adopted. According to the processing sequence, the whitening pressure ratio of the nine rice mills is 6:5:4:3.5:3:2.5:2:1.5:1.

[0040] (4) Arranging the semi-finished products through the whitening process to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com