Preparation method of zirconium phosphate intercalation material for adsorbing phenol

A technology of intercalation material and zirconium phosphate, which is applied in the field of preparation of zirconium phosphate intercalation material, can solve the problem of high cost and achieve the effect of fast speed and simple synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Weigh about 2 g of α-zirconium phosphate and put it into a 100 ml beaker, add 80 ml of 6% butylamine aqueous solution, stir and react at room temperature for 4 hours, filter, fully wash with distilled water 3 times, separate liquid and solid, Dry at room temperature for 24 hours to obtain a zirconium phosphate composite material intercalated with butylamine.

[0015] Weigh 1.5g of the zirconium phosphate composite material prepared according to the above conditions, put it into 100ml of an aqueous solution with a phenol concentration of 1000ppm, shake it in an oscillator at room temperature for 15 minutes, and after liquid-solid separation, use a UV photometer to measure the concentration of the aqueous solution at 270nm. Phenol concentration, the results show that the phenol concentration in the aqueous solution is less than 5ppm.

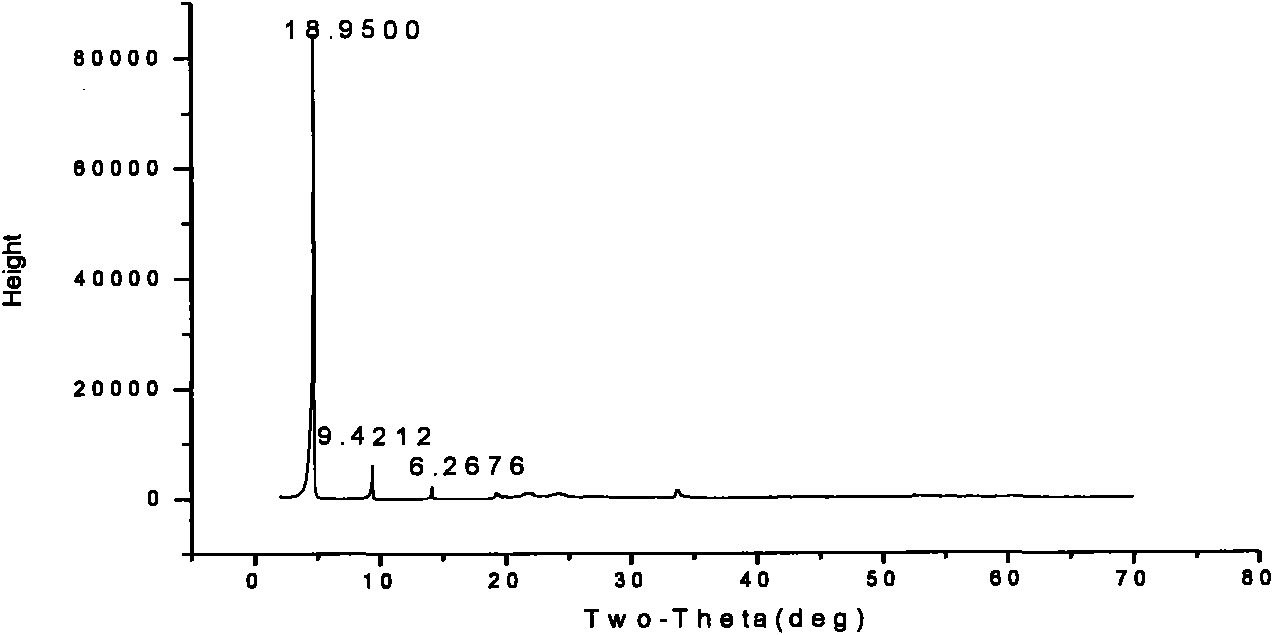

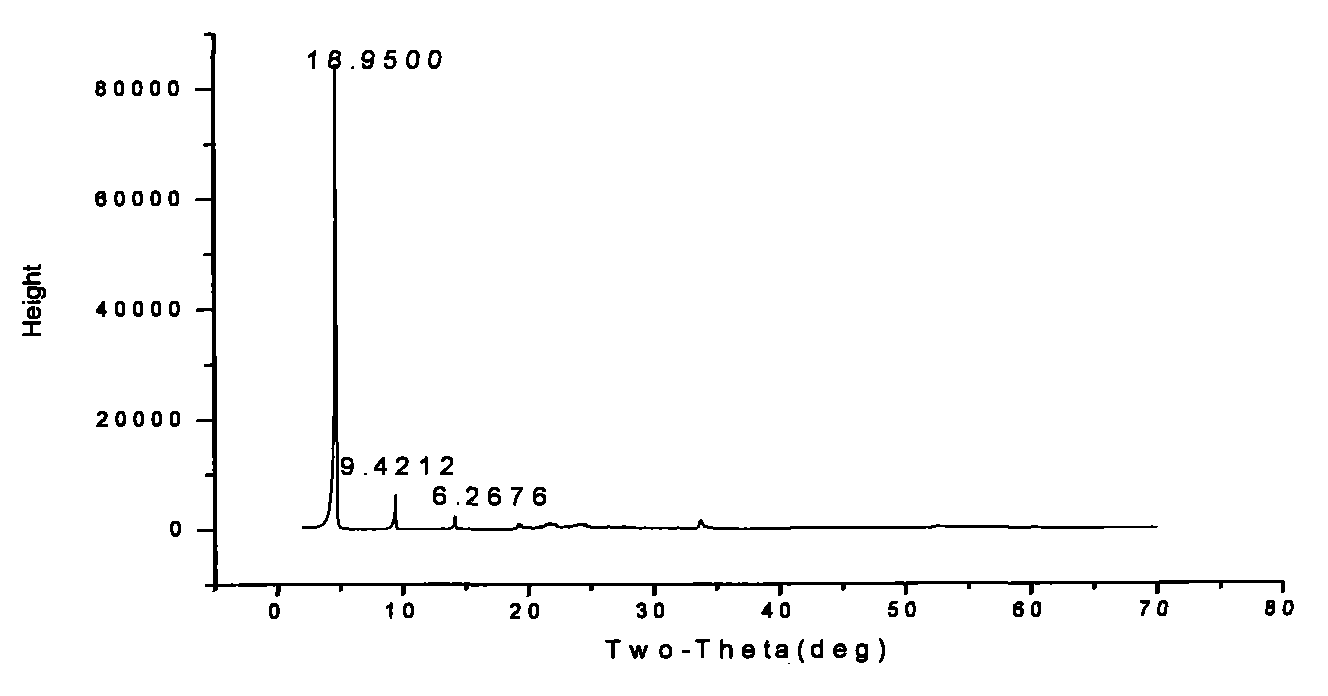

[0016] attached figure 1 The XRD spectrum of the zirconium phosphate composite material intercalated with butylamine prepared ...

Embodiment 2

[0017] Embodiment 2: Weigh about 2 g of α-zirconium phosphate and put it into a 100 ml beaker, add 80 ml of 8% octylamine aqueous solution by weight percentage, stir and react at room temperature for 4 hours, filter, fully wash with distilled water 3 times, separate liquid and solid, Dry at room temperature for 24 hours to obtain a zirconium phosphate composite material intercalated with octylamine.

[0018] Weigh 1g of the zirconium phosphate composite material prepared according to the above conditions, put it into 100ml of an aqueous solution with a phenol concentration of 1000ppm, shake it in an oscillator at room temperature for 20 minutes, and after liquid-solid separation, use a UV photometer to measure the phenol in the aqueous solution at 270nm. Concentration, the results show that the concentration of phenol in the aqueous solution is less than 5ppm.

Embodiment 3

[0019] Example 3: Weigh about 2g of α-zirconium phosphate and put it into a 100ml beaker, add 80ml of aniline aqueous solution with a weight percentage of 10%, stir and react at room temperature for 4 hours, filter, fully wash with distilled water 3 times, separate liquid and solid, and store at room temperature After drying for 24 hours, an aniline-intercalated zirconium phosphate composite material was obtained.

[0020] Weigh 1.5g of the zirconium phosphate composite material prepared according to the above conditions, put it into 100ml of an aqueous solution with a phenol concentration of 1000ppm, shake it in an oscillator at room temperature for 20 minutes, and after the liquid and solid are separated, use a UV photometer to measure the concentration in the aqueous solution at 270nm. Phenol concentration, the results show that the phenol concentration in the aqueous solution is less than 5ppm.

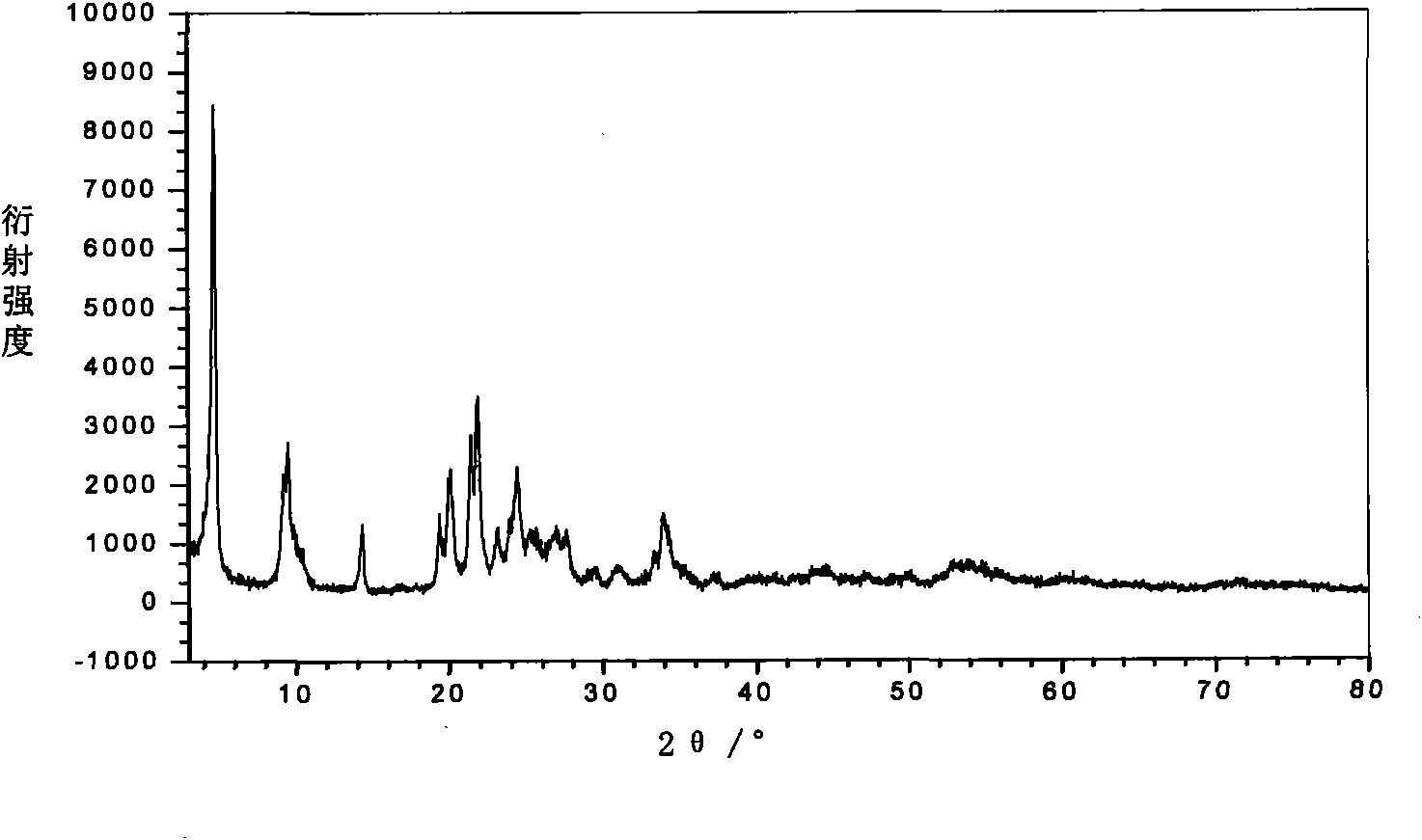

[0021] attached figure 2 The XRD spectrum of the zirconium phosphate compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com