Production method for adding brewer grain fattening pig feed

A production method and technology of brewer's grains, which are applied in the production field of adding brewer's grains to fattening pig feed, can solve the problems of affecting the growth and development of pigs, excessive addition ratio, poor protein quality, etc., achieve rich amino acid types, reduce feed-to-weight ratio, The effect of protein quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

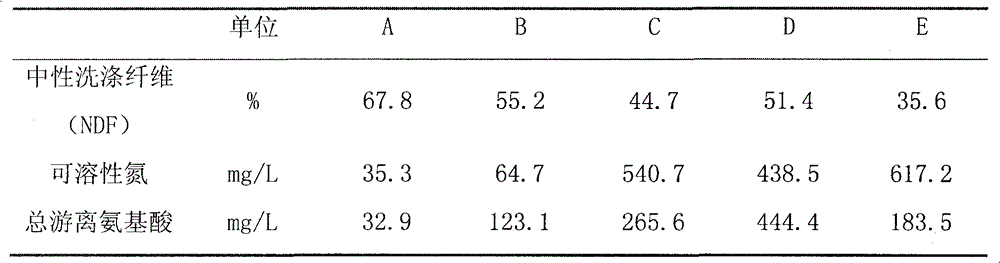

[0013] Embodiment 1, brewer's grain steam explosion pretreatment effect

[0014] The pressure of brewer's grain steam explosion pretreatment is 2Mpa, and the treatment time is 1min. The neutral detergent fiber (NDF) of brewer's grain before blasting was 67.8%, and it was 45.9% after blasting, which decreased by 21.9%, and the effect of fiber reduction was very remarkable.

Embodiment 2

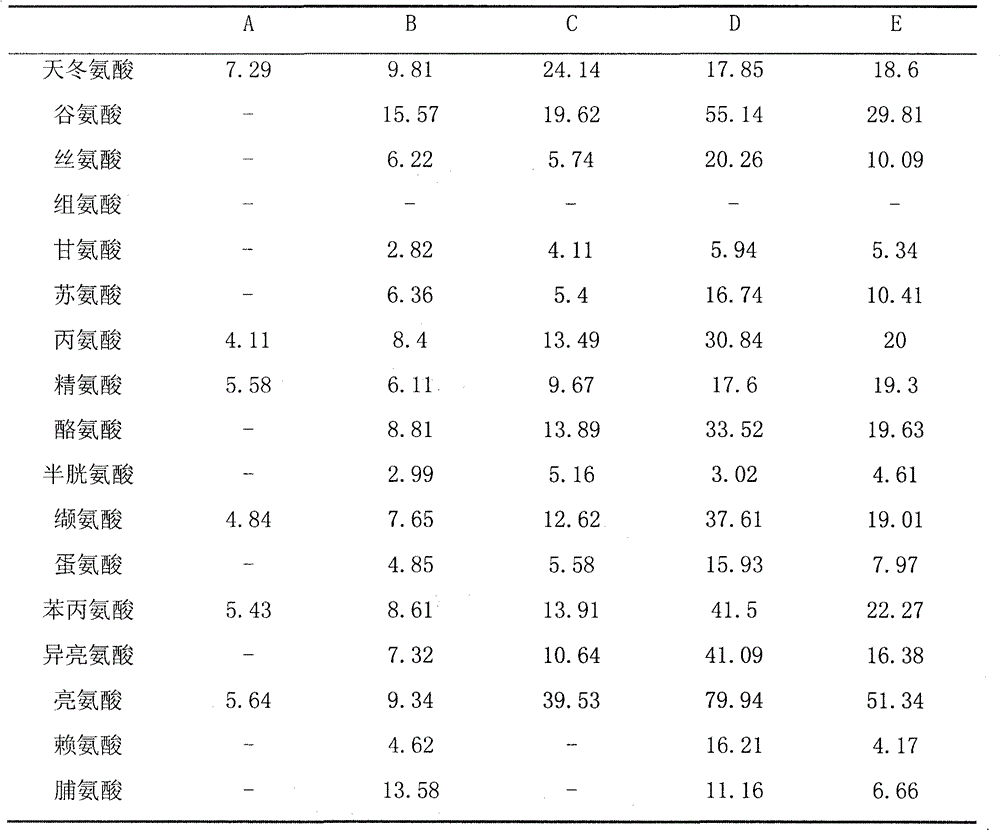

[0015] Embodiment 2, the effect contrast of different fermentation methods

[0016] Fermentation conditions: material-to-water ratio 1:1, temperature 30°C, mixed bacteria (Aspergillus niger: Candida utilis=1:1, the total number of colonies is 1.3×10 11 cpu / g) inoculum amount is 0.05% dry brewer's grain weight and / or add 0.05% compound enzyme, and the fermentation time is 4 days. The composition and activity of the complex enzymes are β-glucanase, activity>4 million U / g compound enzyme; xylanase, activity>2 million U / g compound enzyme; cellulase, CMC enzyme activity> 200,000 U / g compound enzyme; papain, activity > 20,000 U / g compound enzyme; each component is mixed evenly according to the activity value, and each component can be purchased directly in the market, as long as the activity meets the above requirements.

[0017] The different fermentation methods are:

[0018] A: unexploded beer grains, no fermentation;

[0019] B: Unexploded brewer's grains + mixed bacteria for...

Embodiment 3

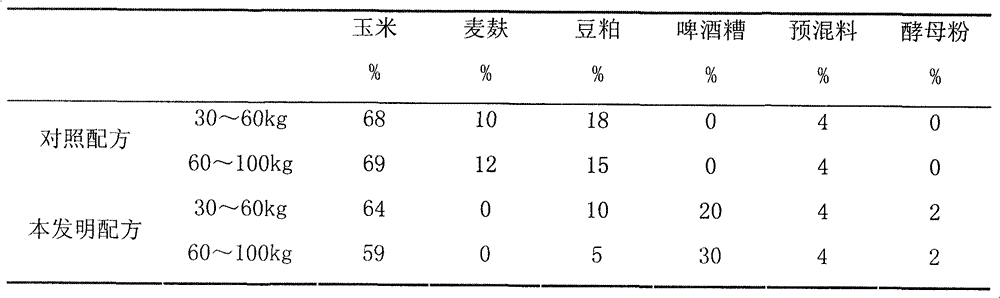

[0031] Embodiment 3, feeding experiment contrast

[0032] The fattening pig feed produced by the present invention is the dietary formula of the fattening pig feed shown in table 3; Carry out feeding experiment in Beijing Tongzhou farm, carry out mixing with other components after fermentation of brewer's grains, then directly feed, feeding cycle is 84 Day, the effect of feeding experiment is shown in Table 4.

[0033] Table 3 Diet formula for fattening pig feed

[0034]

[0035] Adopting the fattening pig feed of the invention reduces the feed-to-weight ratio by an average of 7.1%, increases the daily gain of the fattening pigs by 4.6%, and has no significant difference in the feed intake and growth of the fattening pigs in the test group and the control group.

[0036] Table 4 feeding experiment effect

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com