Method for preparing big-size model test soil body

A model test and large-scale technology, which is applied in the field of layered vibration preparation of large-scale model test soil, can solve the problems of small application range, many factors affecting soil layers, and difficult control of filling quality, so as to achieve cost saving and accurate Effects of Controlling Fill Density and Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

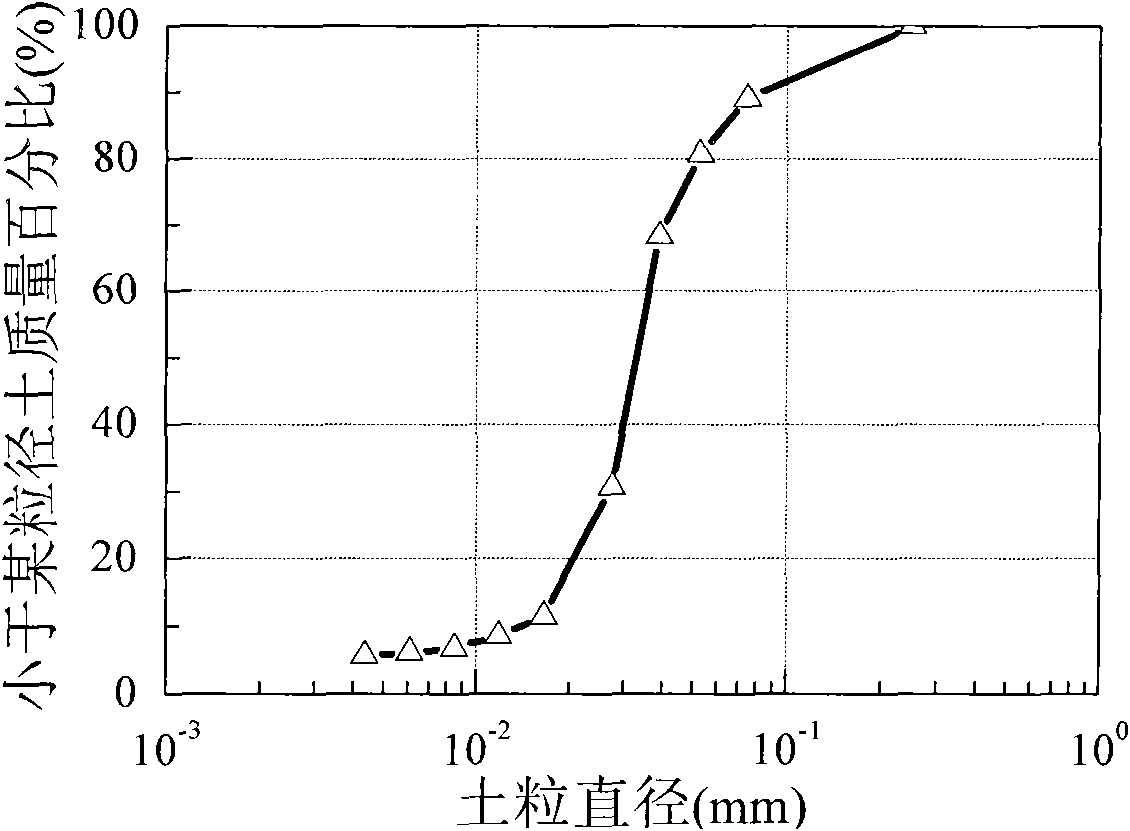

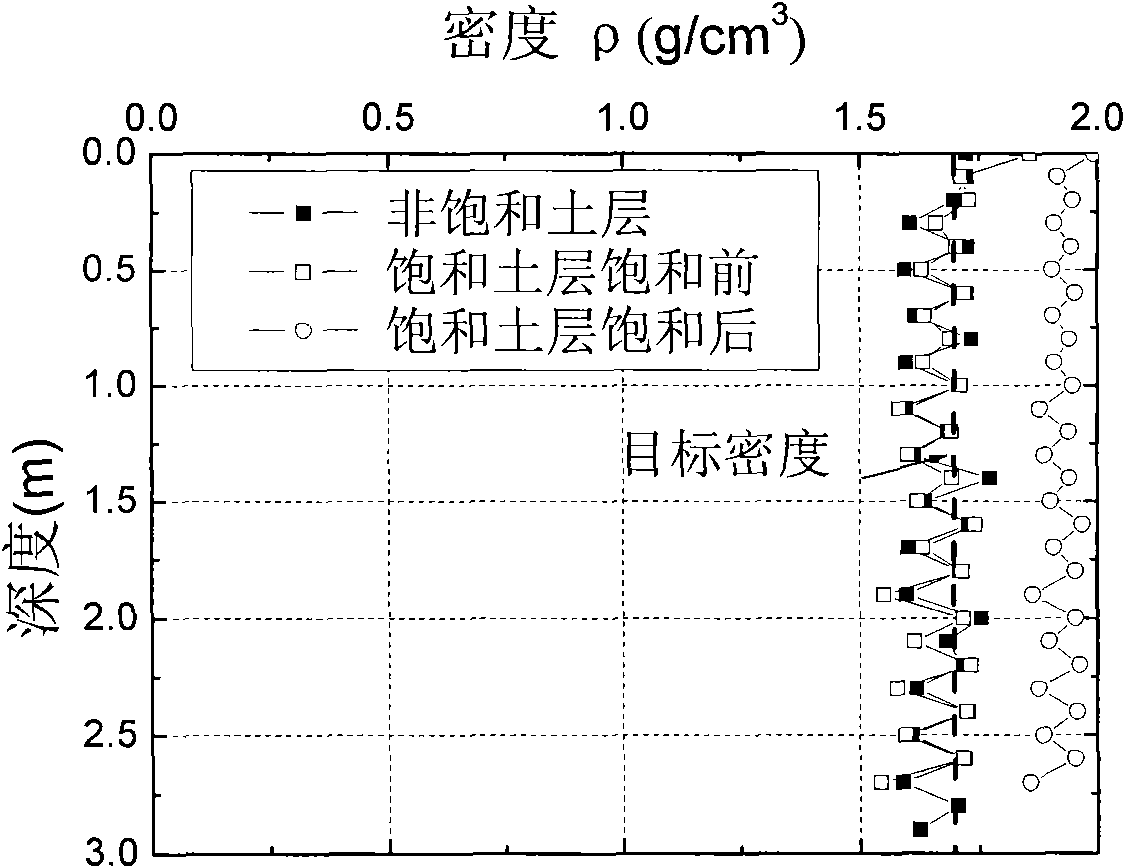

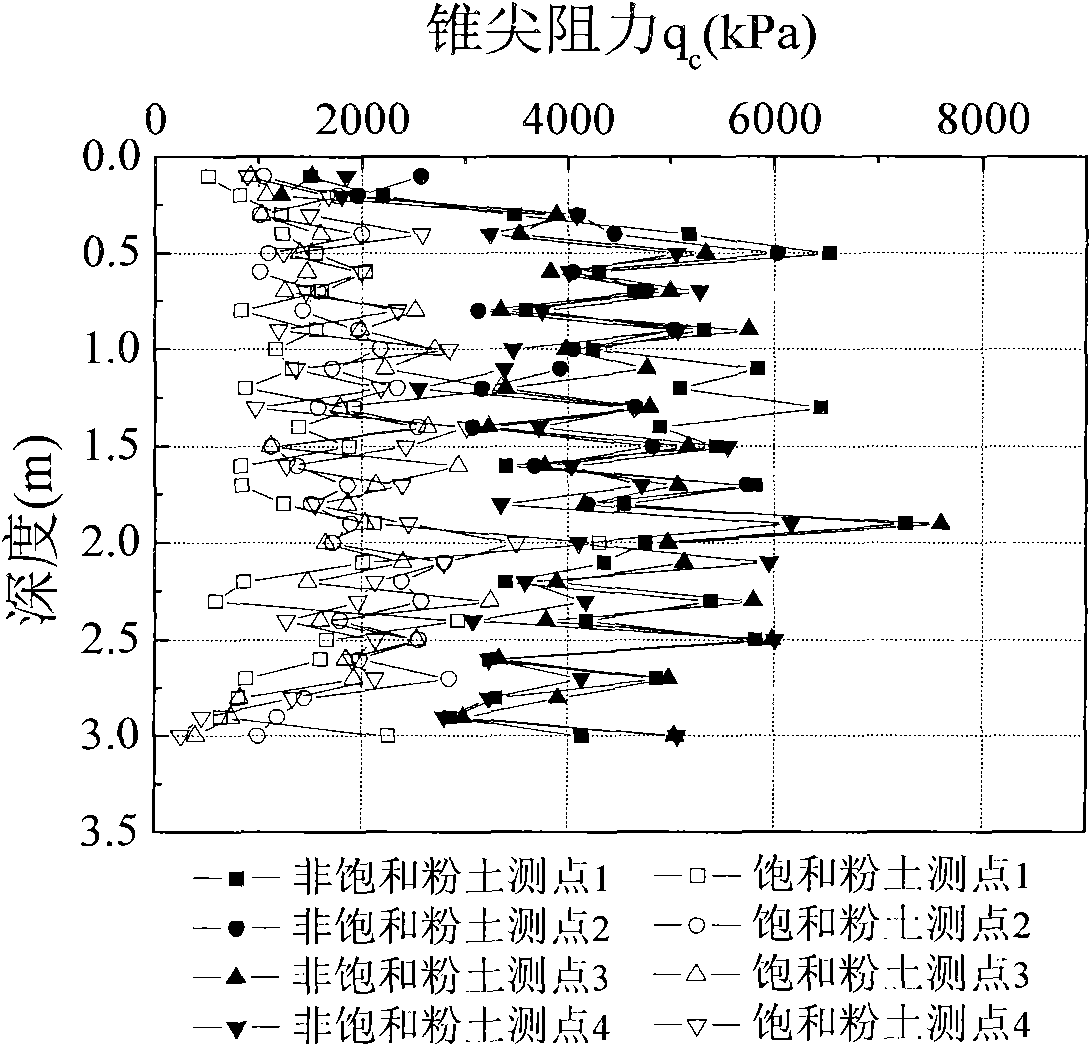

[0035] This embodiment is used to prepare target density in the test tank of 5m * 5m area is 1700kg / m 3 , Unsaturated silt layer and saturated silt layer with a water content of about 15%. figure 1 is the particle fraction curve using silt. The preparation process comprises the following steps:

[0036] 1) The filling scheme is determined;

[0037] 2) Pre-treatment of soil filling;

[0038] 3) Take soil, put soil, and pave the whole;

[0039] 4) Overall vibration;

[0040] 5) Vibration quality inspection;

[0041] 6) Buried test instruments and devices;

[0042] 7) laying the dyeing layer;

[0043] 8) Carry out saturation treatment to model soil;

[0044] 9) In-situ testing of soil properties.

[0045] In the step 1), before the filling scheme is determined, carry out a small-scale vibration test in the early stage, and determine the feasibility of reaching th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com