Large single-stage rubber diaphragm-sealed accumulator unit

A gas storage device and rubber sealing technology, which is applied in the field of gas storage cabinets, can solve problems such as unstable operation parameters of pressurizers, troublesome operation and maintenance of gas cabinets, unstable pressure of gas cabinets, etc., and achieve good results. Economic benefits, reduced maintenance work, and stable gas storage pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

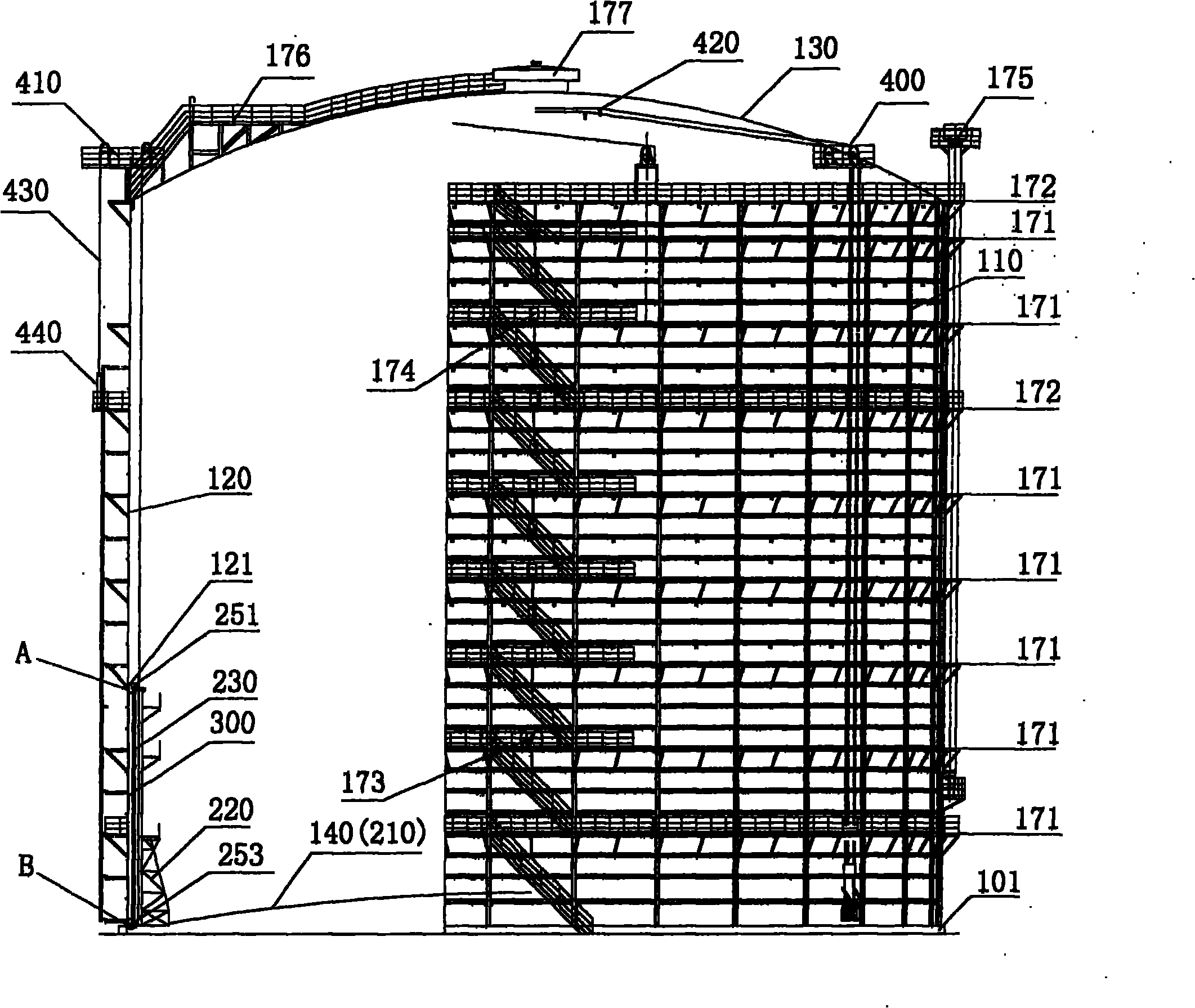

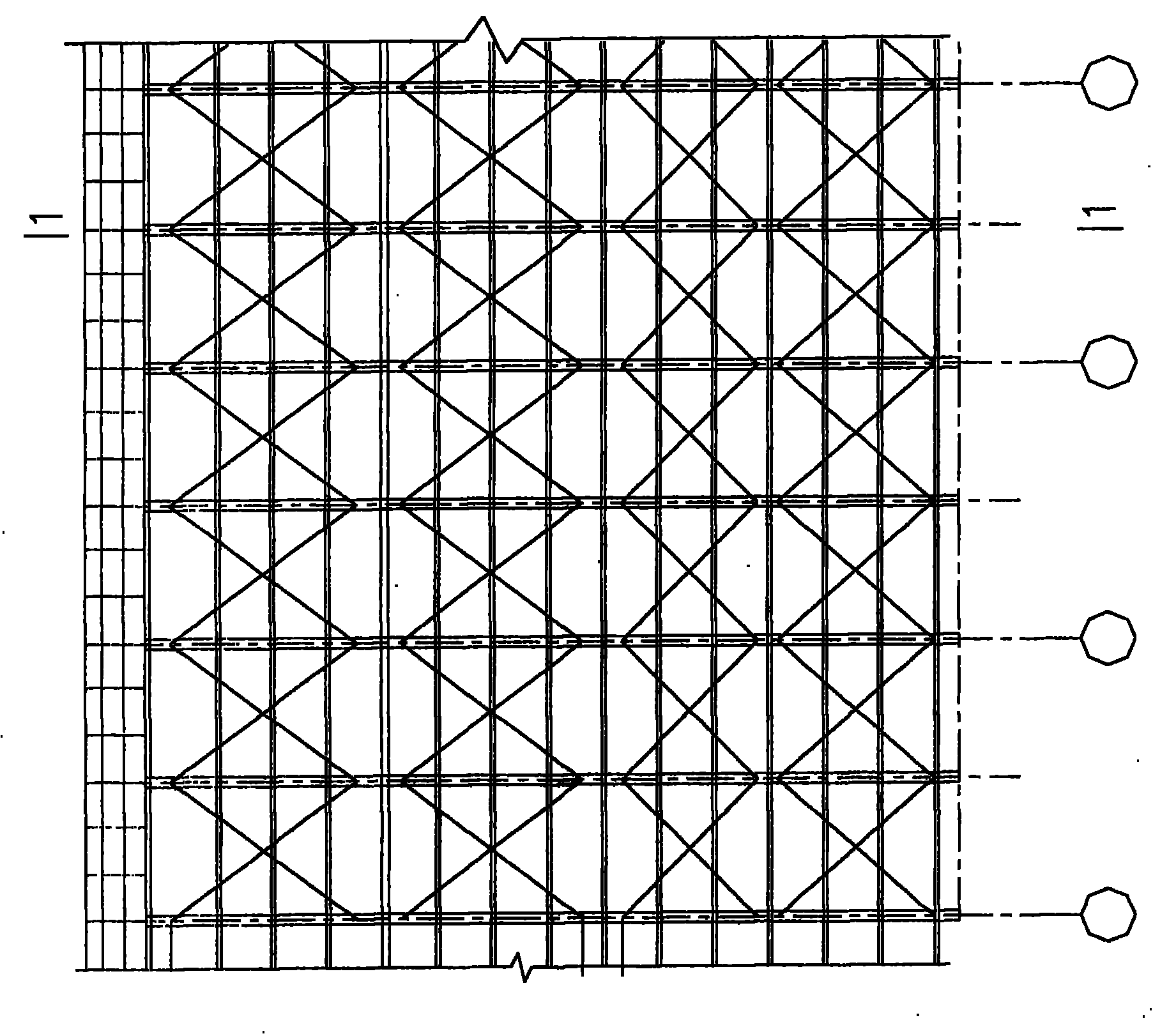

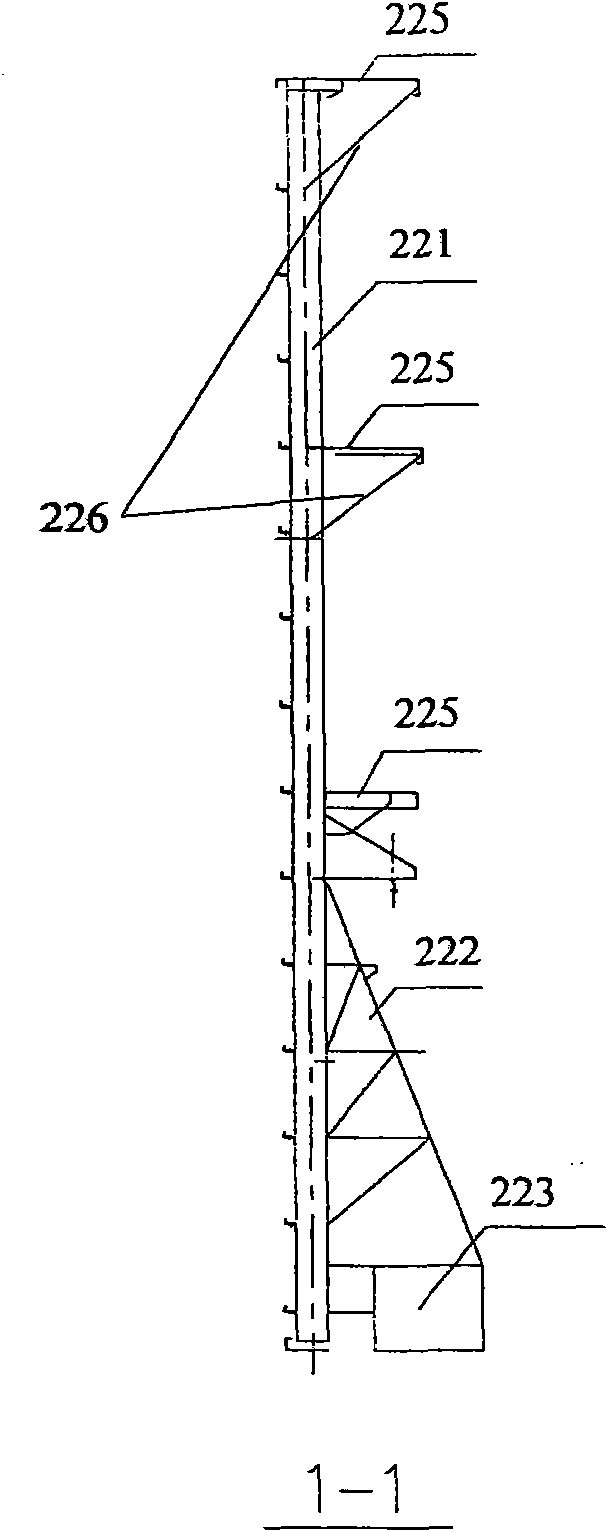

[0038] As shown in the figure, the present invention proposes a large-scale single-stage rubber-membrane-sealed gas storage device. The gas storage device includes a cabinet, a piston, and a sealing film forming a seal between them. The cabinet includes a column, The side plate, the cabinet top plate and the cabinet bottom plate form a cylindrical shell; the inside of the cabinet is provided with a piston that can rise and fall freely, and the rubber sealing film is arranged between the outside of the piston and the side plate of the cabinet, and the The lower edge of the rubber sealing film is connected to the lower part of the piston, and the upper edge is fixed to the inner wall of the side plate of the cabinet to form a single-stage sealed gas storage device; the side plate of the cabinet, the rubber sealing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com