Material monitoring system

A monitoring system and material technology, applied in the direction of continuous material flow weighing equipment, conveyor objects, conveyor control devices, etc., can solve the problems of manual measurement, low accuracy, time-consuming and labor-intensive, etc., to avoid human interference, accurate The effect of metering

Inactive Publication Date: 2010-07-14

李建锋

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, some thermal power plants need to burn some biomass straw in the process of power generation. Since there is no effective monitoring device to measure the amount of mixed combustion, manual measurement is required, which is not only time-consuming and labor-intensive, but also has low accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

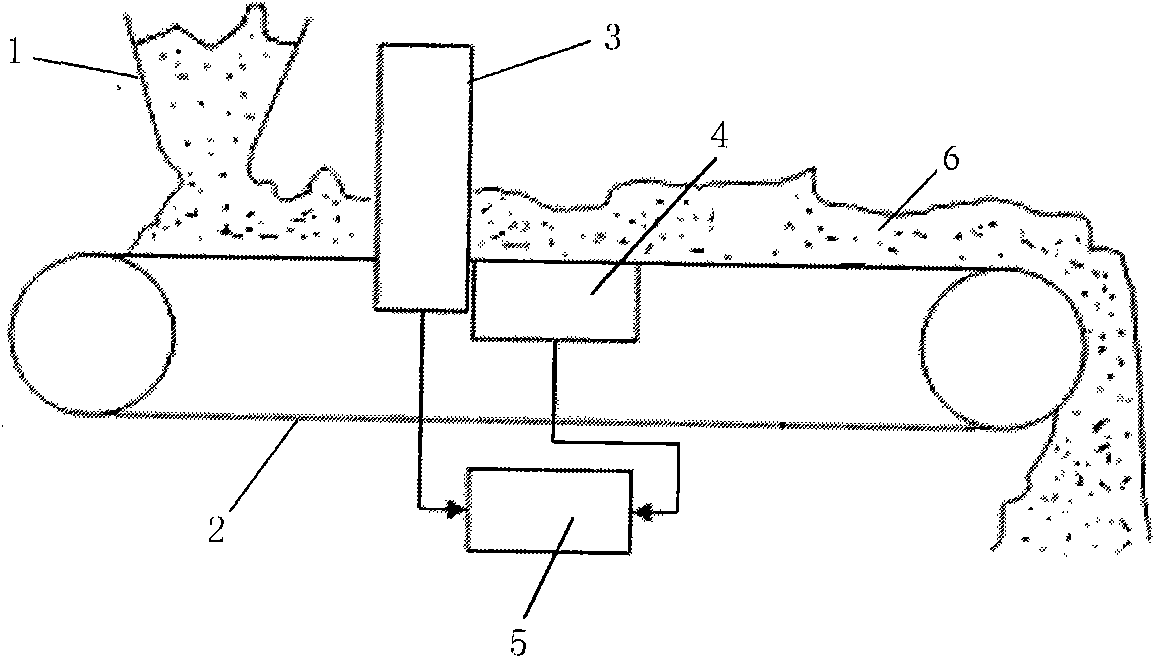

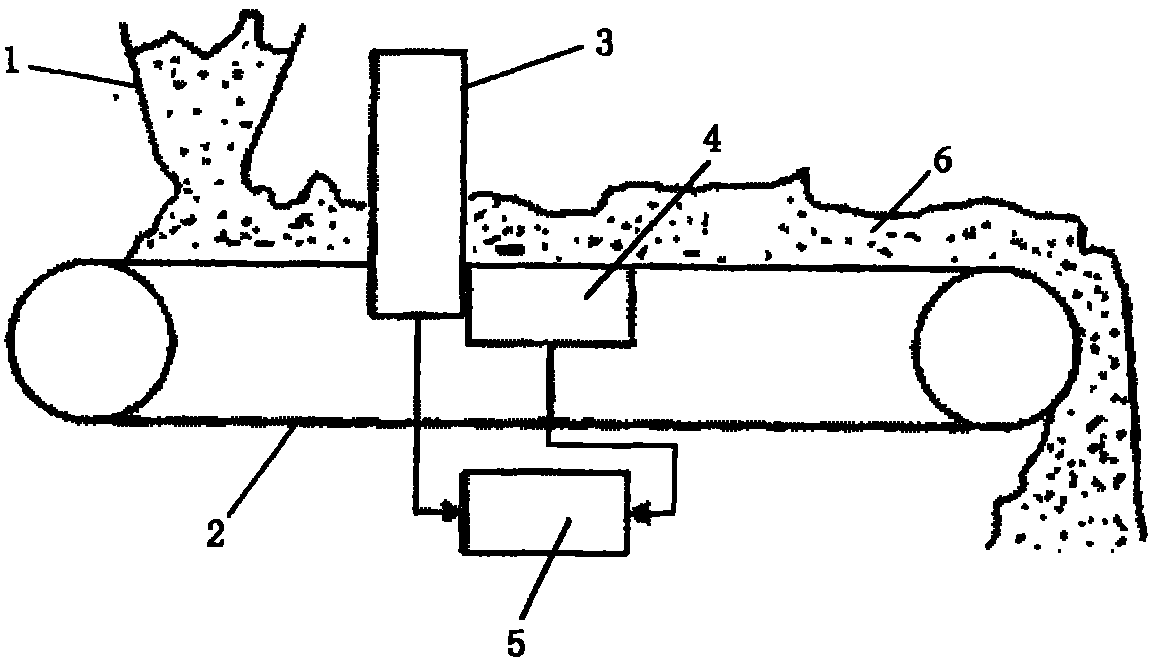

The invention discloses a material monitoring system mainly comprising a hopper, a conveyer belt, ray detectors, a weighing device and a solver, wherein the ray detectors are distributed at the upper and lower parts of the conveyer belt or on two sides thereof; the weighing device is located at the lower part of the conveyer belt; and the signal output terminals of the ray detectors and the weighing device are connected with the signal input terminal of the solver via data wires. Accordingly, the monitoring system is capable of discriminating the components of the material by the ray detectors, weighing the materials by the weighing device and respectively recording the conveying capacities of different materials according to two groups of measurement signals and outputting the data though the wired or wireless network by the solver, thereby avoiding the artificial interference and achieving the accurate measurement of the materials.

Description

technical field [0001] The invention relates to a monitoring system for metering the conveyed quantities of different materials. Background technique [0002] At present, some thermal power plants need to co-burn some biomass straw during the power generation process. Since there is no effective monitoring device to measure the amount of co-firing, manual measurement is required, which is not only time-consuming and labor-intensive, but also has low accuracy. Contents of the invention [0003] Aiming at the deficiencies in the prior art, the present invention aims to provide a material monitoring system with simple structure, convenient use and accurate measurement. [0004] The technical scheme adopted in the present invention is: [0005] A material monitoring system, including a hopper, a conveyor belt, a radiation detector, a weighing device and a calculation device, the radiation detector is arranged on the upper, lower or both sides of the conveyor belt, the weighin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G43/08B65G15/00B65G47/16G01G11/00

Inventor 李建锋

Owner 李建锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com