Sheet-grasping mechanical arm of full-automatic battery plate printing machine

A technology for cell and printing presses, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of reduced material transmission efficiency, unsuitable for mass production, material damage, etc., to ensure accuracy, compact structure, and fast action. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

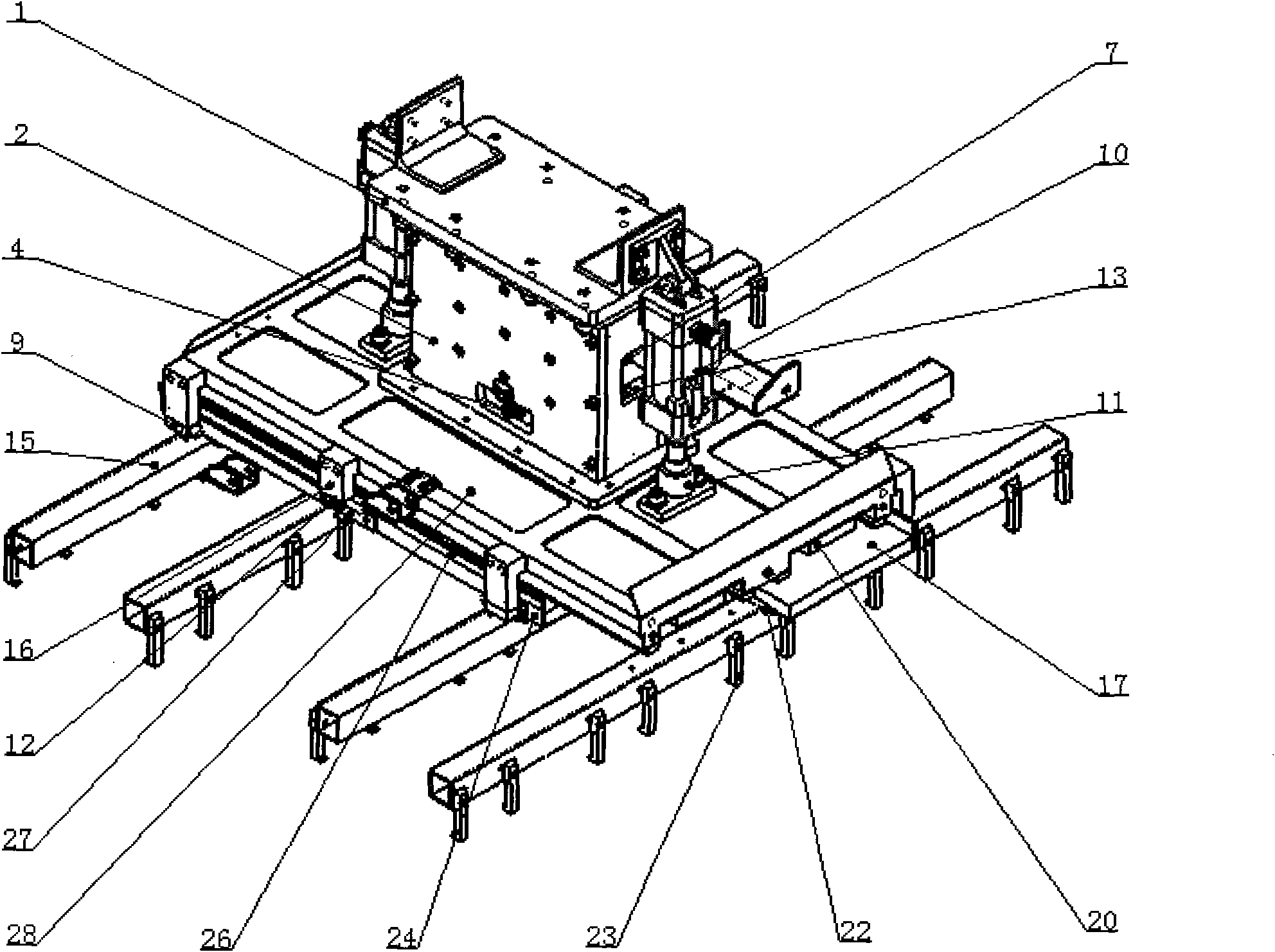

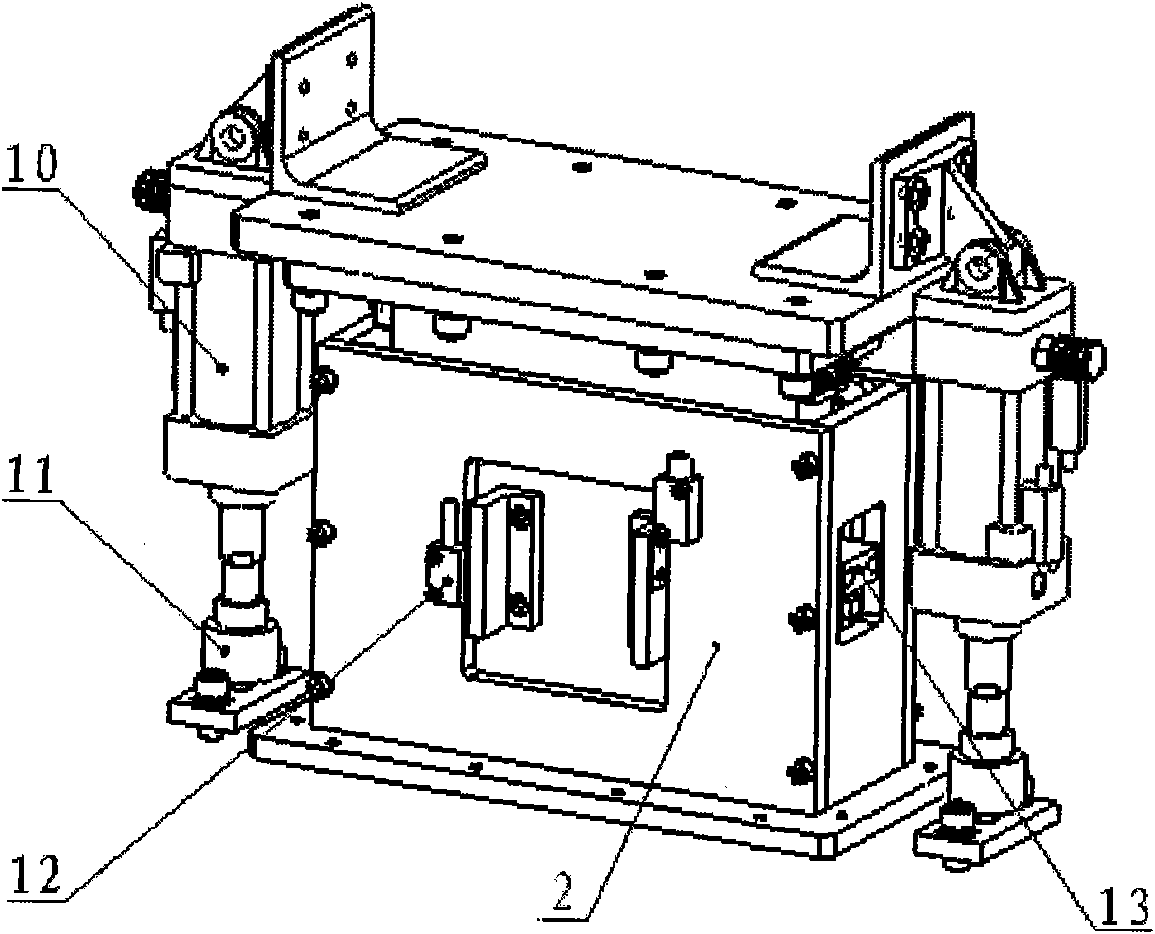

[0030] attached by figure 1 - attached Figure 3-3 As shown in the embodiment, the present embodiment includes a vertical motion mechanism and a horizontal motion mechanism, and a front hand mechanism 29 and a rear hand mechanism 30 are provided in the horizontal motion mechanism. The structure of the front hand mechanism 29 and the rear hand mechanism 30 is the same, wherein Described front hand mechanism 29 comprises pawl piece installation beam 15,33, hand paw seat 17, pawl piece 23, sensor mounting plate 24, magnetic grid 26 and induction sheet 27; Parallel claw mounting beams 15, 33 have 5 pairs of claws 23 evenly distributed in groups on one side of each claw mounting beam. The lower end of the sheet 23 is provided with a supporting sheet 32, and the claw sheet installation beam 15 is fixedly connected with the mover 18 of the linear motor through the claw seat 17, and the 2-5 pairs of claw sheets of the claw sheet installation beam 15 on the front hand mechanism 29 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com