Fish meat sausage and production method thereof

A technology of fish sausage and fish meat, which is applied in the field of preparing new type of seaweed fish sausage, which can solve the problems of dry taste, poor elasticity, increase the content of fat and cholesterol in sausage, and achieve the effect of increasing sales and increasing the processing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 A seaweed fish sausage, choose silver carp surimi 14kg, pork 2kg, cornstarch 2kg, laver pulp 5kg, salt 0.48kg, oil 1.2kg, rice wine 0.2kg, monosodium glutamate 0.1kg, egg white 0.4kg, green onion and ginger Juice 0.07kg.

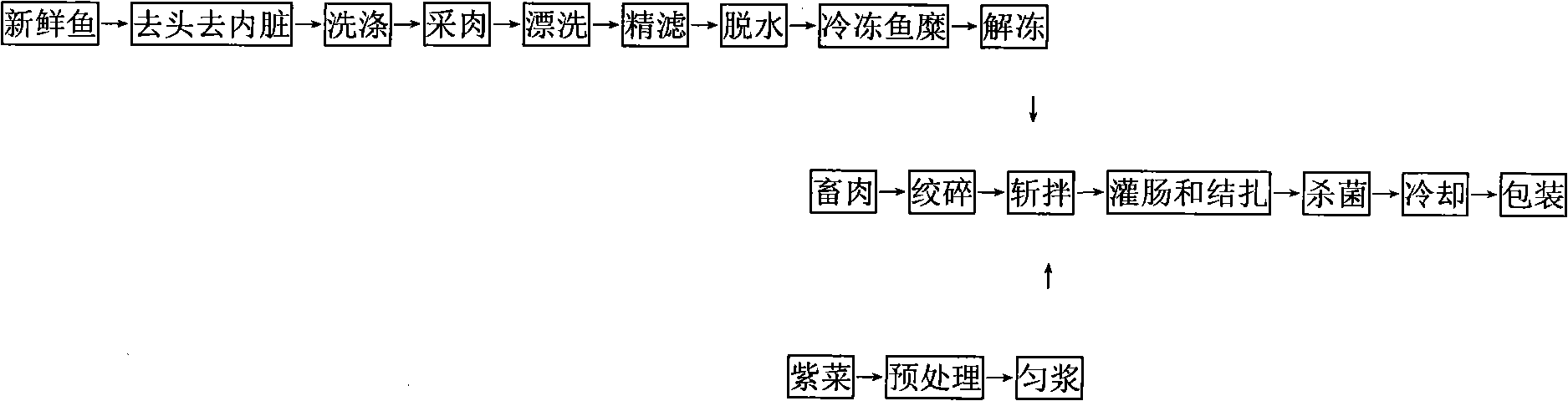

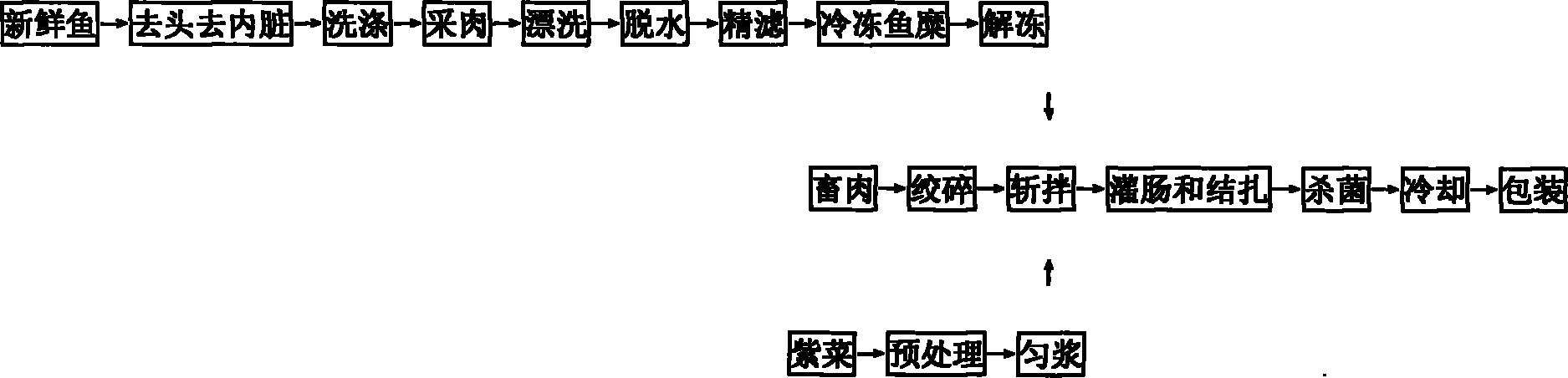

[0021] A kind of preparation method of seaweed fish sausage, the preparation technological process of seaweed fish sausage see figure 1 , including the following steps:

[0022] 1) Pretreatment of seaweed: wash the seaweed with water to remove the salt and dirt on the surface, soak it in water to make it fully absorb water, take it out after about half an hour, then wash the surface with clean water, and cut it into filaments Putting it into a pulverizer for pulverization to obtain a coarse slurry containing laver fragments, and then performing pulverization and homogenization again to obtain a laver slurry.

[0023] 2) Preparation of frozen surimi: laparotomy, head and viscera of fresh silver carp are performed to prevent fish gallbladder...

Embodiment 2

[0025] Example 2 A seaweed fish sausage, its formula is (unit: kg): salmon surimi 7, sea pomfret surimi 8, corn starch 1, tapioca starch 1, pork 2.5, laver pulp 5, salt 0.40, peanut oil 0.6, corn Oil 0.6, rice wine 0.1, monosodium glutamate 0.1, egg white 0.4, green onion ginger juice 0.07; the rest are the same as in Example 1.

Embodiment 3

[0026] Embodiment 3 A kind of seaweed fish sausage, its formula is (unit kg): grass carp surimi 6, carp surimi 4, yellow croaker surimi 3, cornstarch 0.5, potato starch 1.5, pork 3, laver pulp 4, salt 0.4, Palm oil 1.2, rice wine 0.2, monosodium glutamate 0.1, egg white 0.4, green onion ginger juice 0.07; the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com