Sounding device

A sounding device and thermal sounding technology, applied to sounding devices, instruments, sensors, etc., can solve the problems of heating air, affecting the sounding effect of the thermal sounding membrane 120, and not revealing the sounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

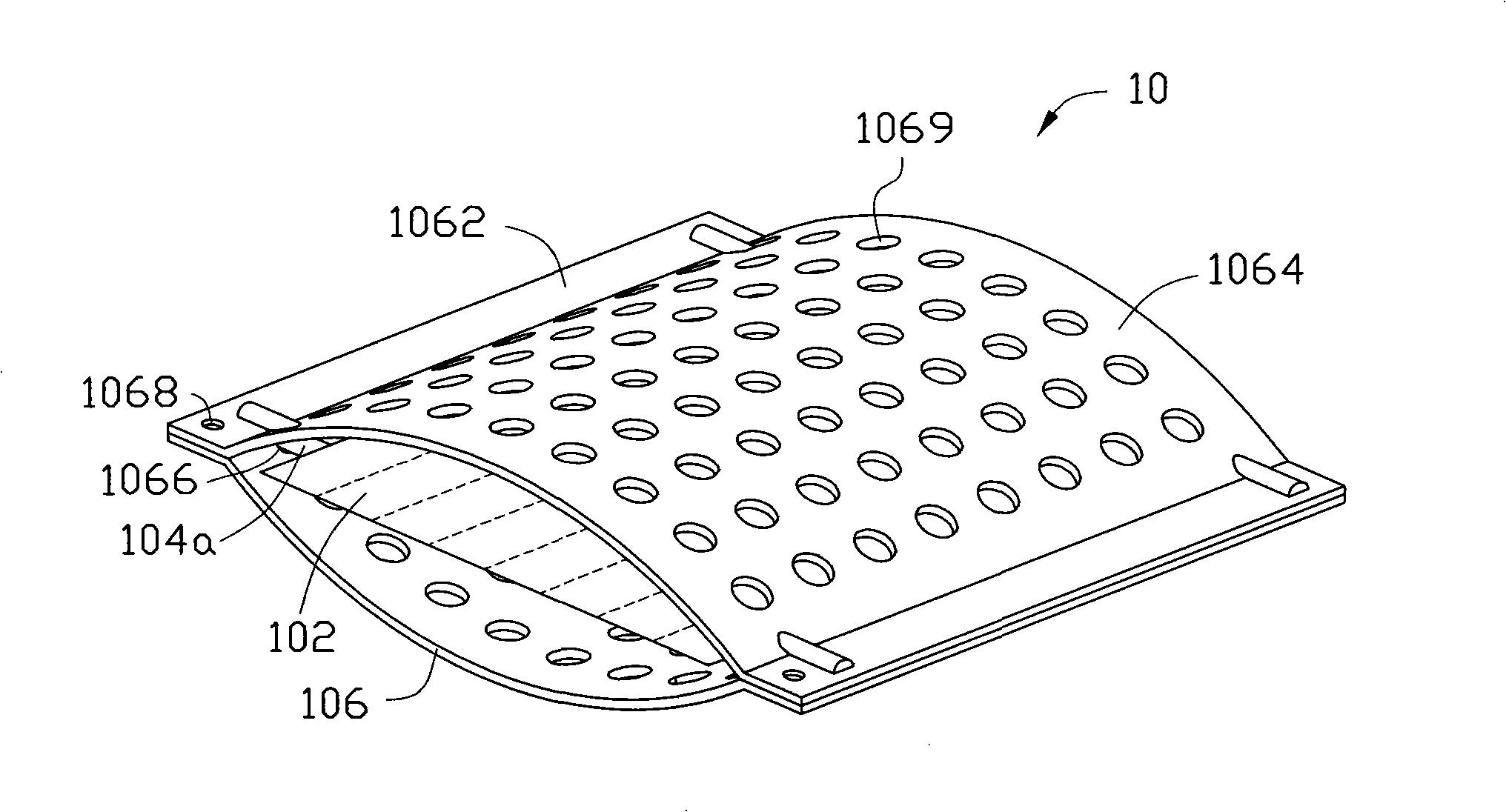

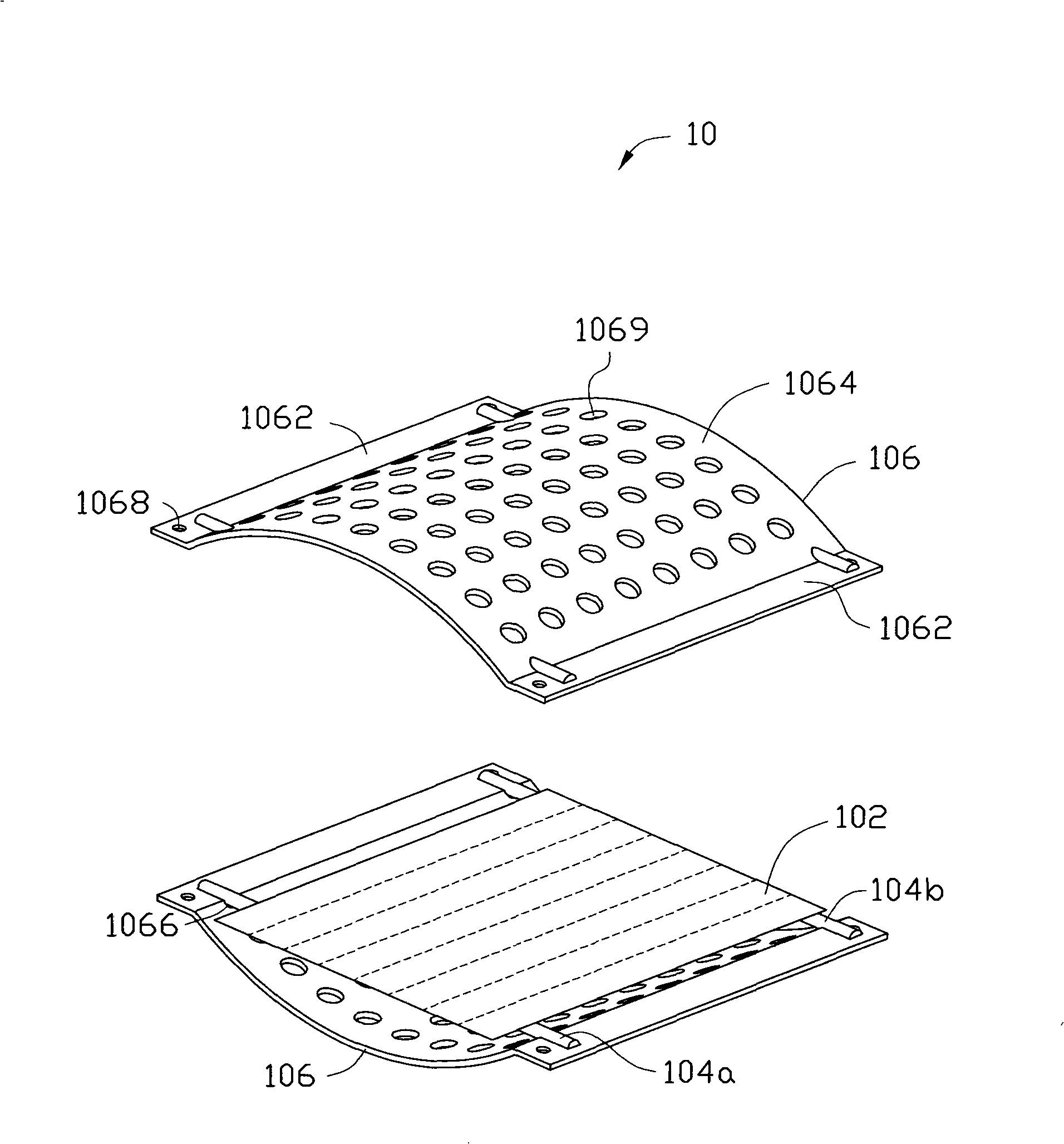

[0019] The sound generating device of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0020] see Figure 2 to Figure 3 , The first embodiment of the present invention provides a sounding device 10, the sounding device 10 includes a thermal sounding film 102, at least one first electrode 104a, at least one second electrode 104b, two plate-shaped protective structures 106. The at least one first electrode 104 a and the at least one second electrode 104 b are fixed by the plate-shaped protective structure 106 . The thermosound film 102 is disposed between the first electrode 104a and the second electrode 104b, and is fixed by the first electrode 104a and the second electrode 104b. The thermal acoustic membrane 102 can receive signals input from the first electrode 104a and the second electrode 104b to emit sound waves. The two plate-shaped protective structures 106 are arranged on both sides of the thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com