Multiple needle sewing machine

A multi-needle sewing machine, sewing machine technology, applied in the direction of sewing machine components, sewing machine needle holders, program-controlled sewing machines, etc., can solve problems such as having to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

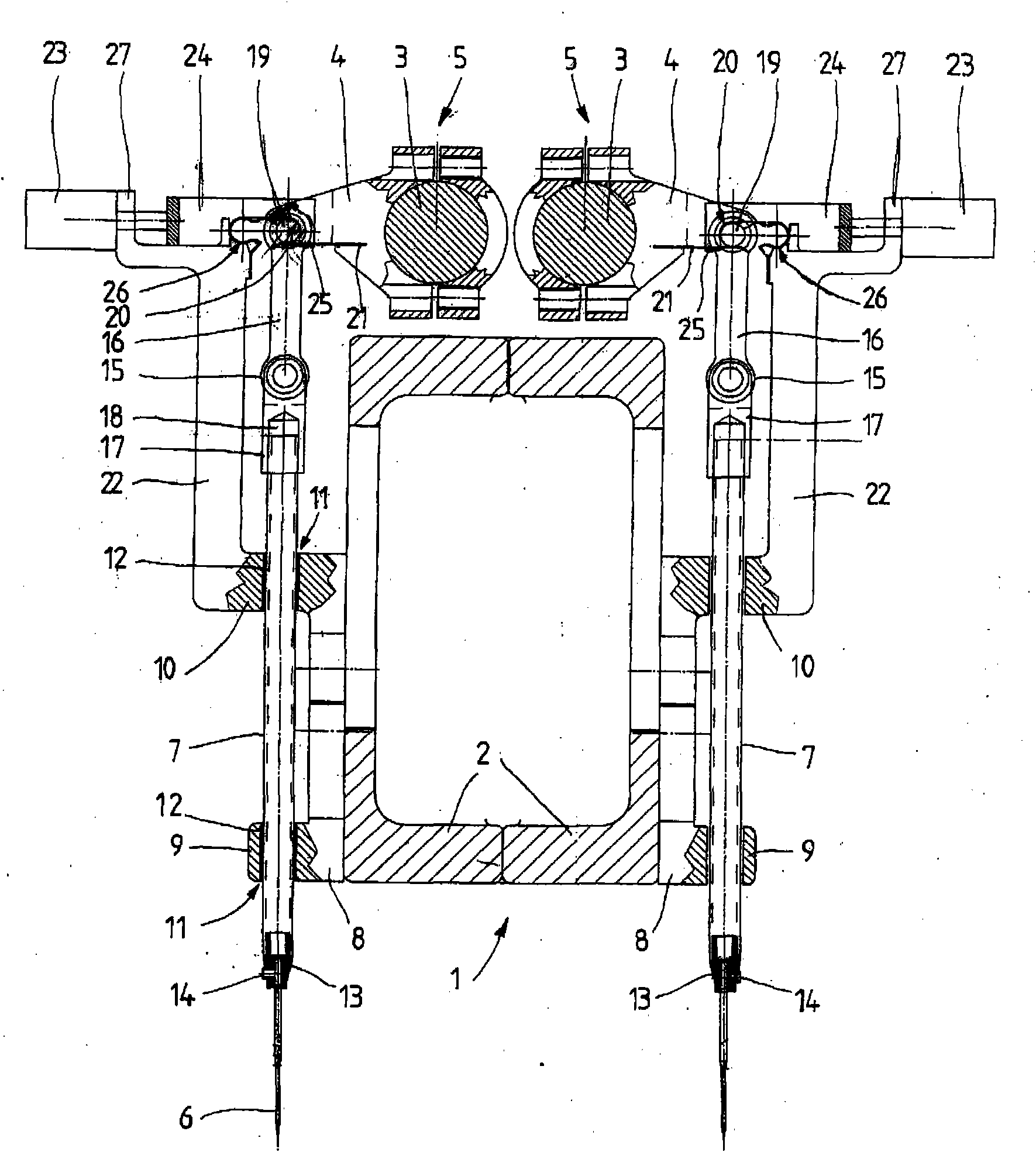

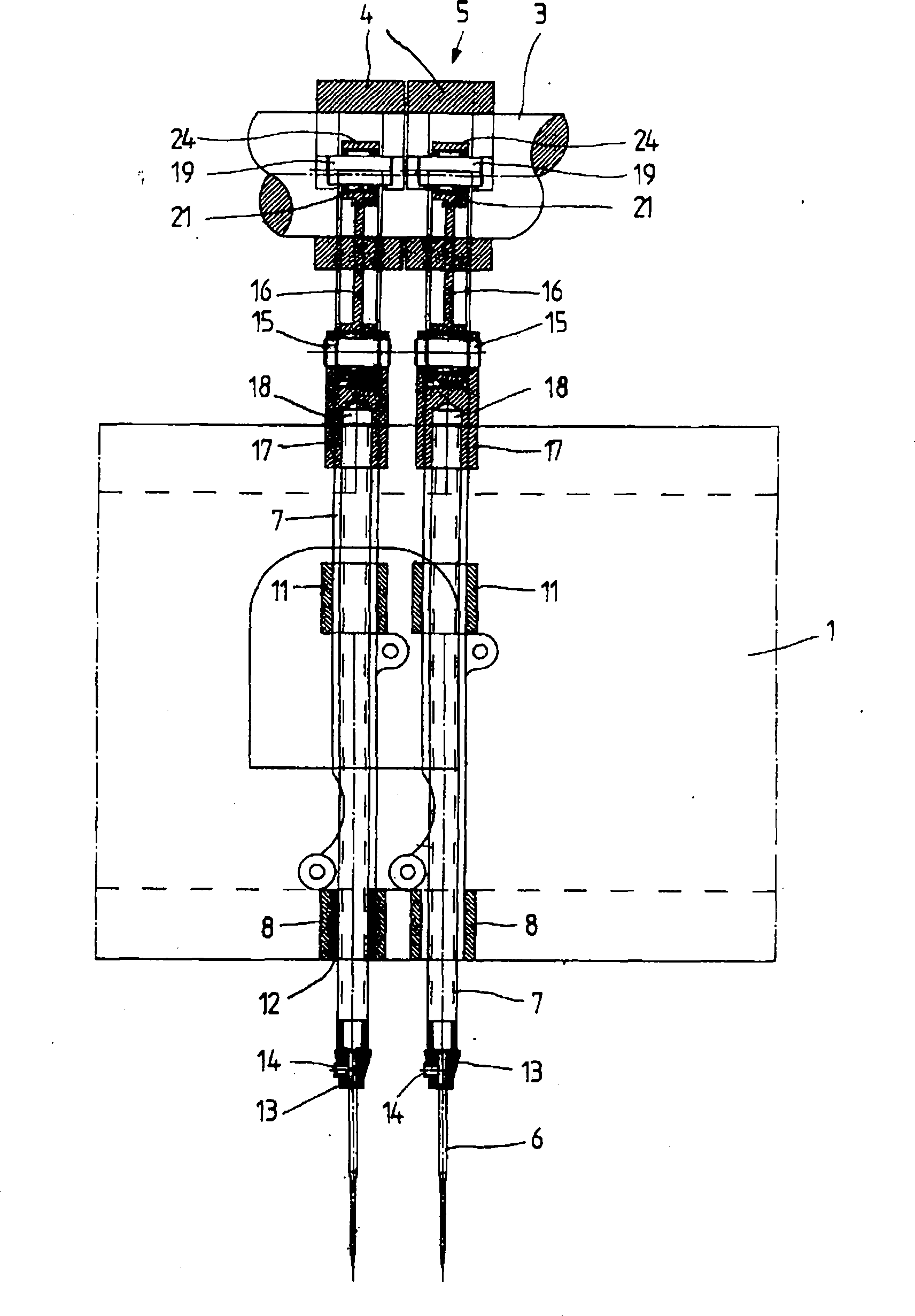

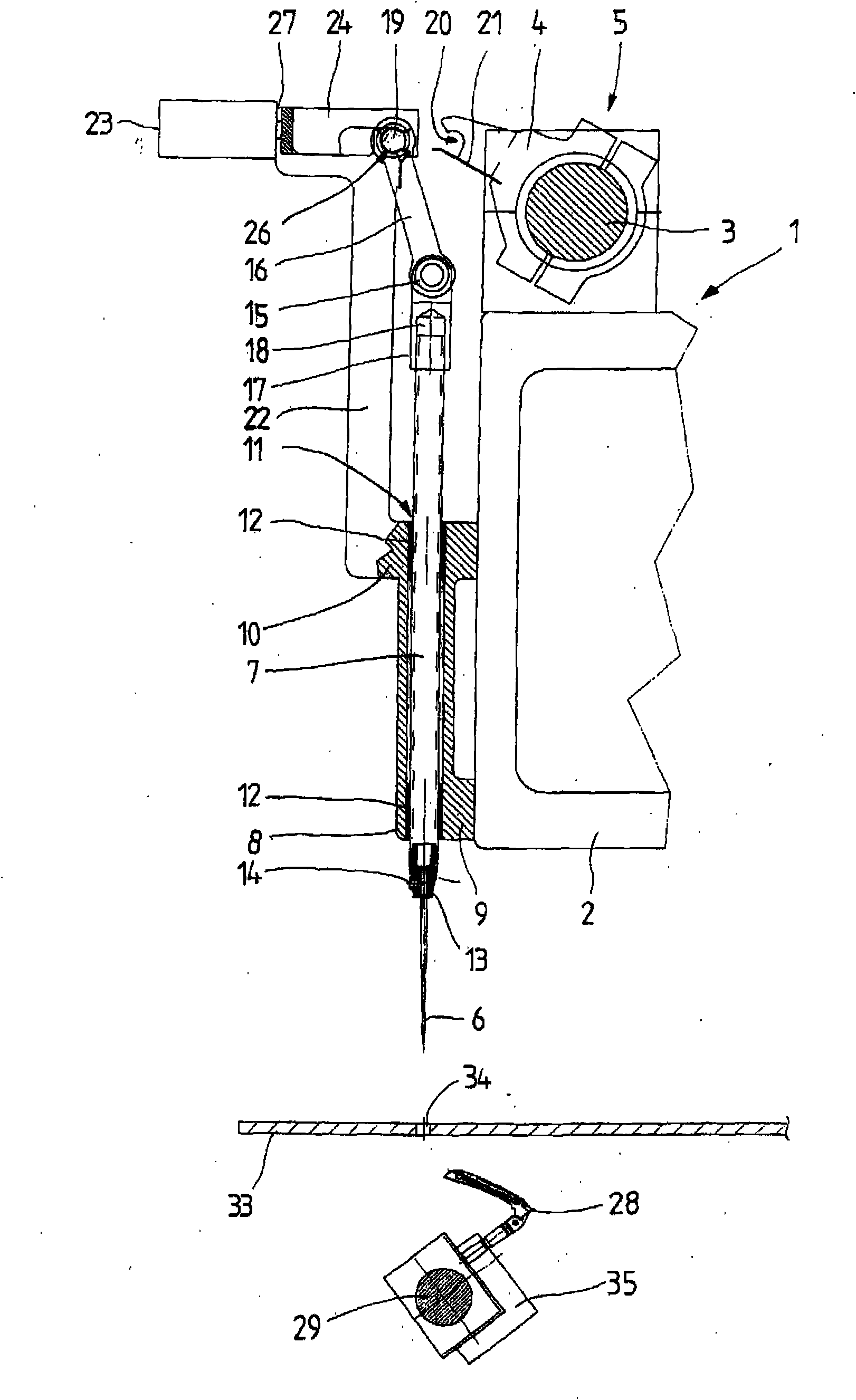

[0062] figure 1 is a cross-sectional view of rack 1. The frame 1 is formed from two U-shaped elements 2 , whose legs are aligned with one another, so that a box-like frame 1 is formed. On the frame 1, the drive shaft 3 extends parallel to the longitudinal direction of the needle head 1, the drive shaft 3 is fixed in rotation with the cam 4, and the cam 4 and the drive shaft 3 form a driver 5 for the needle 6, the driver 5 The drive shaft 3 moves in an oscillating manner, and the oscillating motion of the drive shaft 3 is converted into a translational motion of the needle 6 .

[0063] The needle 6 is arranged at a support element 7 capable of performing a translational movement by means of the drive 5 . The mounting support 7 is guided on guide elements 8 fixed on both sides of the frame 1, each guide element 8 has two legs 9, 10, the two legs respectively contain inner holes 11, the holes 11 are the same The shafts are aligned and have sliding bearings 12 fixed inside. Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com