Filler for sewage treatment and preparation method thereof

A technology for sewage treatment and preparation, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., and can solve the problems of low biomass and poor activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

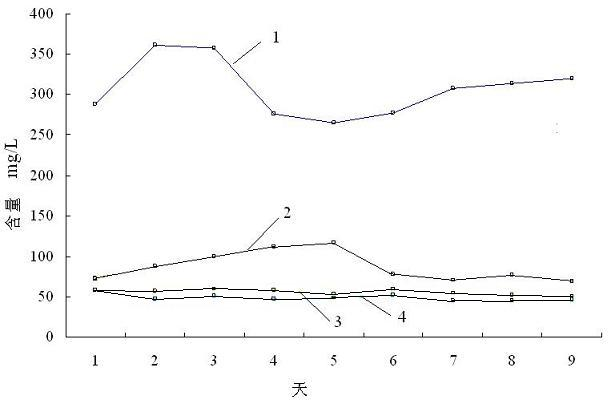

Image

Examples

specific Embodiment approach 1

[0011] Specific Embodiment 1: The filler for sewage treatment in this embodiment consists of 77 to 90 parts by weight of polyurethane foam, 0.1 to 0.5 parts of microbial growth promoter, 0.1 to 0.3 parts of microbial activity activator, 2 to 7 parts It is made of active biological enzyme preparation and 8-15 parts of activated sludge.

[0012] The biomass attached to the filler for sewage treatment in this embodiment has reached 30kg / m 3 above.

[0013] The prepolymer of diphenylmethane diisocyanate and polyether polyol in the polyurethane foam material in this embodiment are under the condition that foaming agent, catalyst, foam stabilizer and diffusion agent exist when necessary, adopt commonly used Process preparation; wherein the density of polyurethane foam is 30kg / m 3 , the porosity is 25 mesh, the tensile is 250, the hardness is 2.7, and the rebound is 40%.

[0014] The activated sludge in this embodiment is taken from the activated sludge used to treat domestic sewa...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the filler for sewage treatment consists of 80 to 85 parts of polyurethane foam, 0.2 to 0.4 parts of microbial growth promoter, and 0.15 to 0.25 parts of microorganisms in parts by weight. It is prepared by active activator, 4-6 parts of active biological enzyme preparation and 10-12 parts of activated sludge. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the filler for sewage treatment consists of 83 parts by weight of polyurethane foam, 0.3 part of microbial growth promoter, 0.2 part of microbial activity activator, 5 parts The active biological enzyme preparation and 11 parts of activated sludge are made. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com