Gas flow reverse control method of ventilation air methane thermal oxidation device of coal mine

A control method and wind gas technology, which are applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as unstable operation of oxidation devices, and achieve the effects of improving automatic operation stability and high methane oxidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

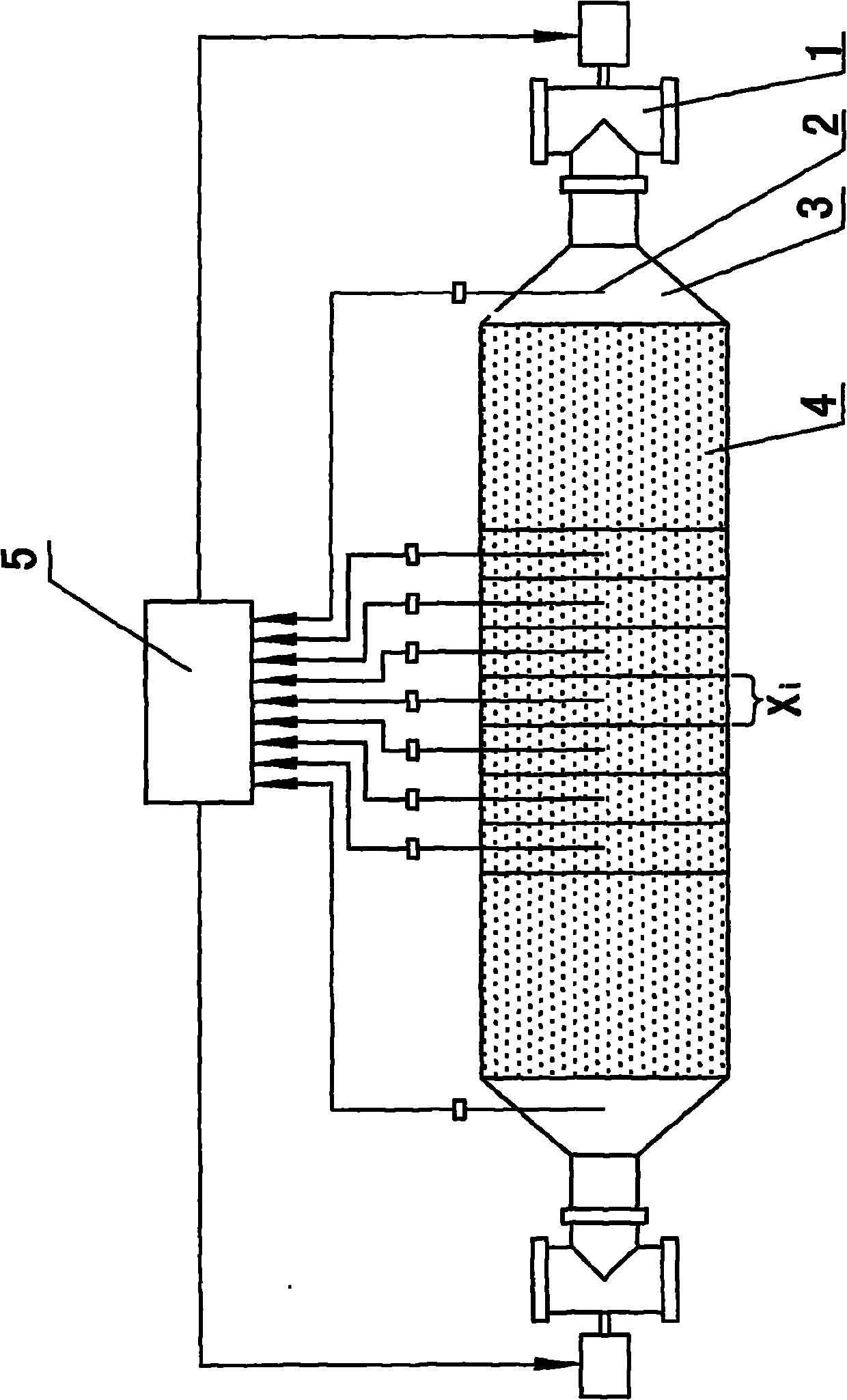

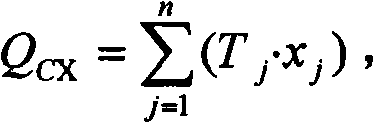

[0029] Such as figure 1 As shown, seven thermocouples 2 are evenly arranged along the airflow direction in the central area of the oxidation bed 4, and one thermocouple 2 is arranged at the inlet and outlet 3 at both ends of the oxidation bed 4, and the programmable controller 5 is based on the data collected by the above thermocouple 2 , calculate the length of the area with a temperature ≥ 900°C in the central area of the oxidation bed 4, the line heat storage in the central area of the oxidation bed 4, and the gas temperature difference between the two inlets and outlets of the oxidation bed 4, and judge whether to reverse the direction according to the calculation results. If it is necessary to reverse the direction , the programmable controller 5 outputs a signal to the reversing valve 1 to switch the gas flow direction.

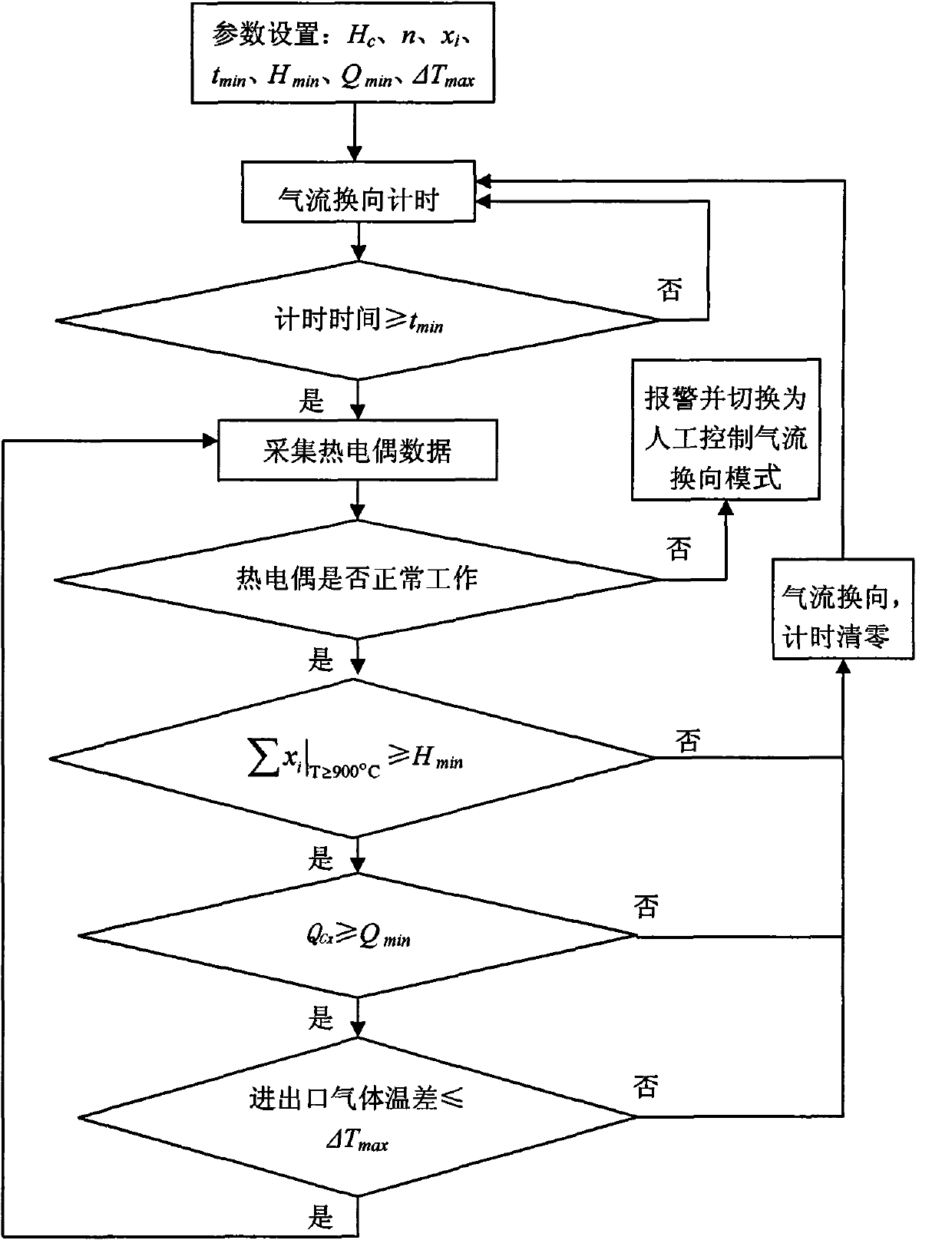

[0030] Such as figure 2 As shown, the airflow reversing control method of the coal mine exhaust air gas thermal oxidation device includes the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com