Refrigeration cycle device

A refrigeration cycle and refrigerant technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of less refrigerant and poor power recovery efficiency, and achieve the effect of improving the degree of freedom of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

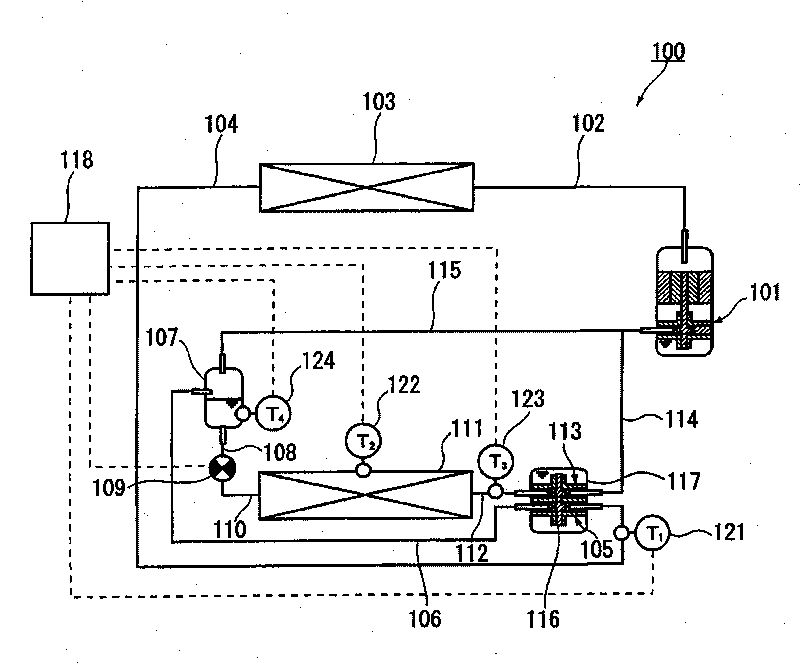

[0048] Such as figure 1 As shown, the refrigeration cycle device 100 includes: a high-pressure stage compressor 101 , a radiator 103 , an expander 105 , a gas-liquid separator 107 , an expansion valve 109 , an evaporator 111 , and a low-pressure stage compressor 113 .

[0049] The low-pressure stage compressor 113 pre-compresses the gas refrigerant evaporated in the evaporator 111 . The high-pressure stage compressor 101 further compresses the refrigerant (working fluid) precompressed by the low-pressure stage compressor 113 . The expander 105 recovers power by expanding the refrigerant cooled by the radiator 103 . In addition, the expander 105 is configured to pass the entire amount of the refrigerant cooled by the radiator 103 . That is, a bypass circuit for flowing the refrigerant bypassing the expander 105 is not provided. Since the entire amount of the refrigerant contributes to the power recovery, the improvement effect of the COP (coefficient of performance) by the ...

no. 2 approach

[0109] Figure 9 It is a block diagram of the refrigeration cycle apparatus of 2nd Embodiment of this invention. The refrigeration cycle device 500 of the present embodiment has the same structure as the refrigeration cycle device 100 of the first embodiment (refer to figure 1 ) roughly the same structure. This embodiment differs from the first embodiment in that the temperature sensor 520 and the control by the controller 118 are provided. Hereinafter, the same reference numerals are assigned to the same functional components, and description thereof will be omitted.

[0110] like Figure 9 As shown, the refrigeration cycle apparatus 500 includes a temperature sensor 520 for detecting the temperature of the refrigerant discharged from the high-pressure stage compressor 101 . Similar to the first embodiment, a temperature sensor 122 for detecting the evaporation temperature of the refrigerant in the evaporator 111 is also provided. The controller 118 controls the opening...

no. 3 approach

[0116] Figure 11 It is a configuration diagram of a refrigeration cycle apparatus according to a third embodiment of the present invention. The refrigeration cycle device 700 has substantially the same configuration as the refrigeration cycle devices described in the first and second embodiments. This embodiment differs from the first embodiment in that the high-pressure stage compressor 701 , the low-pressure stage compressor 713 , and the expander 705 are housed in a common airtight container 717 .

[0117] like Figure 11 As shown, in the refrigeration cycle apparatus 700, the high-pressure stage compressor 701, the low-pressure stage compressor 713, and the expander 705 are arranged in a single airtight container 717 in this order from the top. The low pressure stage compressor 713 and the expander 705 are connected by a shaft 716 and can transmit power through the shaft 716 . Oil is accumulated at the bottom of the airtight container 717 . The space above the oil sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com