Roller bearing and sealing joint with improved dynamic behaviour

A technology for rolling bearings and sealing pads, which is applied in the field of rolling space of sealing pads and wheel bearings, and can solve problems such as lip wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

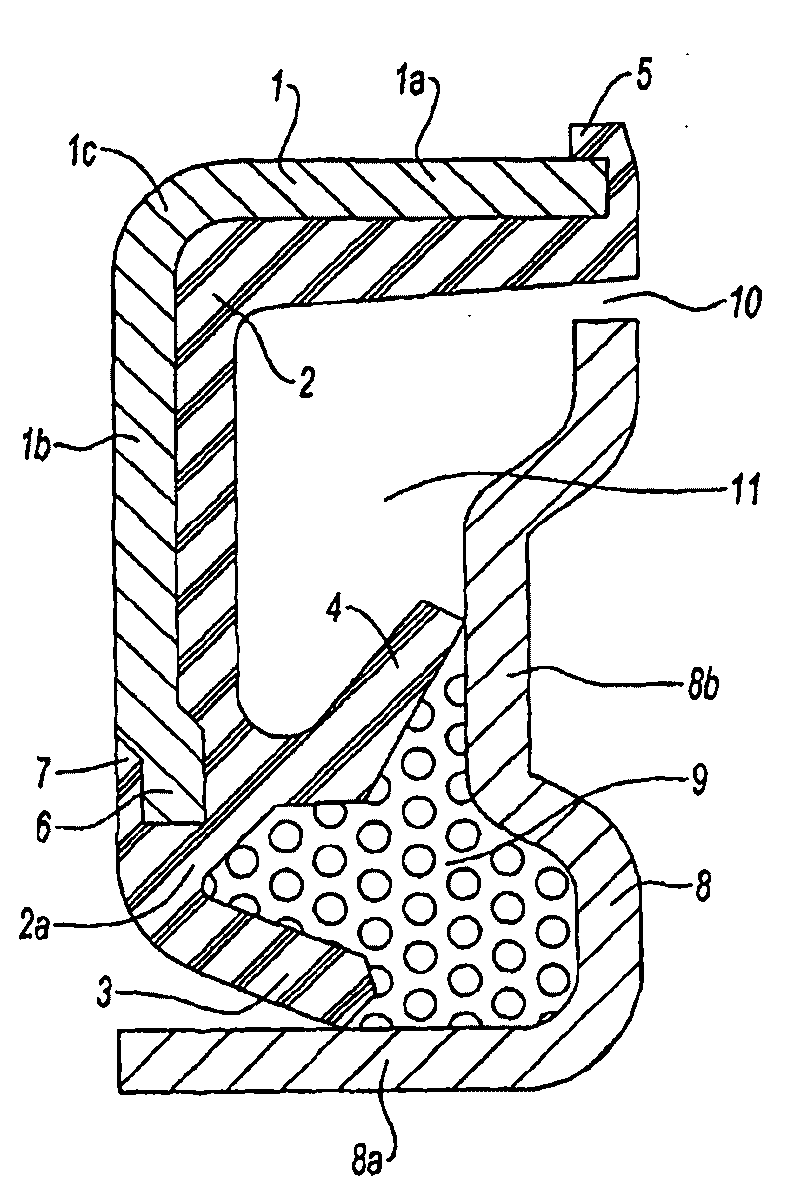

[0013] Refer now figure 1 A gasket for rolling bearings, especially for rolling bearings of automobile wheels, is described.

[0014] The bearing includes a fixed component, a rotating component and some rolling elements. The rolling elements are placed in a rolling space formed between the components so that they can rotate relatively.

[0015] In order to seal one side of the rolling space, the bearing is equipped with a gasket, which includes a rigid ring frame 1 combined with the bearing, so that the frame is connected to a member of the bearing in rotation. In particular, the frame 1 can be realized with a metal material, especially a stamped steel plate. According to an embodiment, each side of the rolling space can be sealed with a gasket.

[0016] In the illustrated embodiment, the skeleton 1 includes an axial support surface 1a and a radial support surface 1b, which are connected by a connecting fillet 1c. In this way, by assembling on the corresponding supporting surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com