Air sucking device and semiconductor processing device

A technology of air extraction device and processing device, which is used in semiconductor/solid-state device manufacturing, electrical components, gaseous chemical plating, etc., can solve the problems of complex maintenance and operation, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

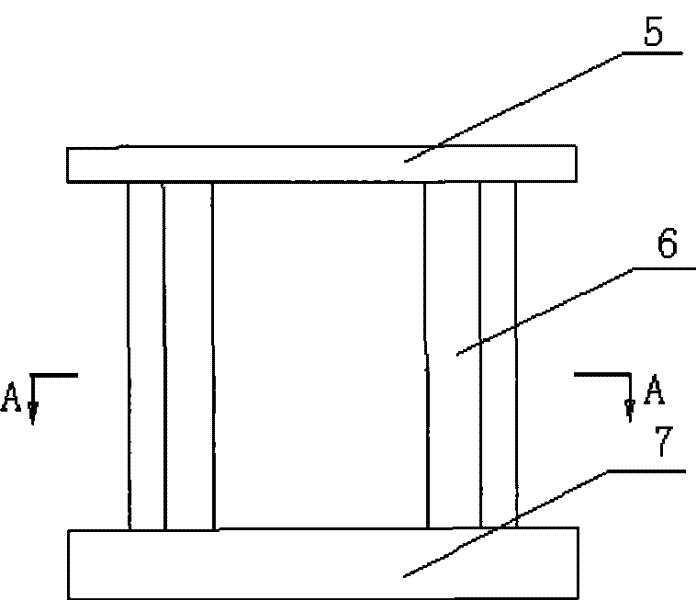

[0023] Such as image 3 — Figure 6 As shown, the air extraction device is a cylindrical structure with a cavity 9 inside, and the side wall 6 of the cylindrical structure is provided with 3 openings 10 and 3 gas passages 8, 3 openings 10 and 3 gas passages 8 spaced apart from each other. In fact, three fan-shaped side walls that are evenly distributed along the circumference of the circular cylinder are dug out, and the remaining side walls are made into a hollow structure.

[0024] The upper and lower ends of the cylinder are provided with connecting flanges 5 and 7, and ring-shaped sealing grooves and bolt mounting holes can be respectively provided on the top of the upper flange 5 and below the lower flange, so that it is convenient to connect with other equipment and ensure sealing etc.

[0025] The lower end flange 7 may be a blind flange, and the middle part of the lower surface of the blind flange is recessed upward to form a uniform flow cavity 11 .

[0026] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com