Flat panel display of right-angle bending pair-group grid controlled cathode structure and manufacturing process thereof

A technology of flat panel display and cathode structure, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., to achieve the effects of improving success rate, simple manufacturing process, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the embodiments.

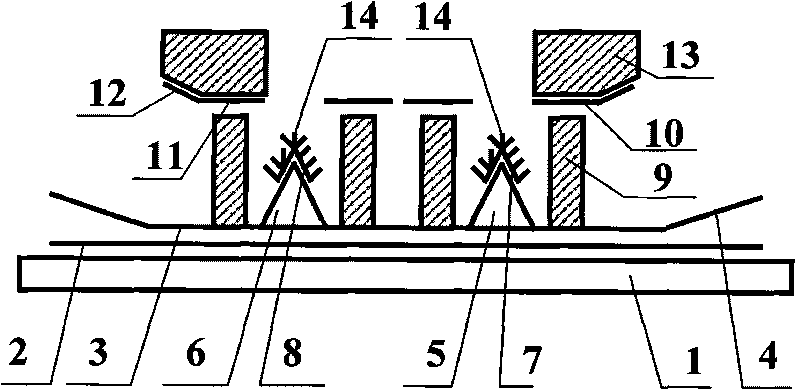

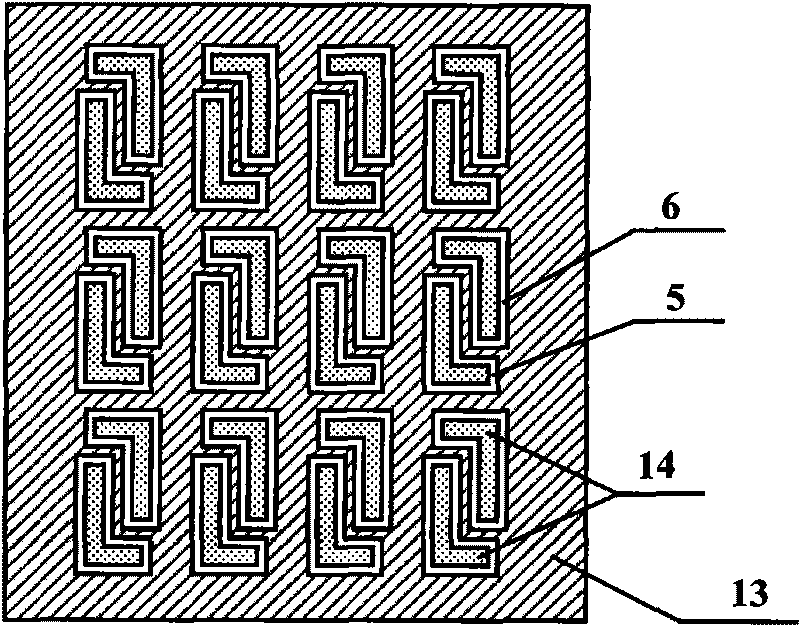

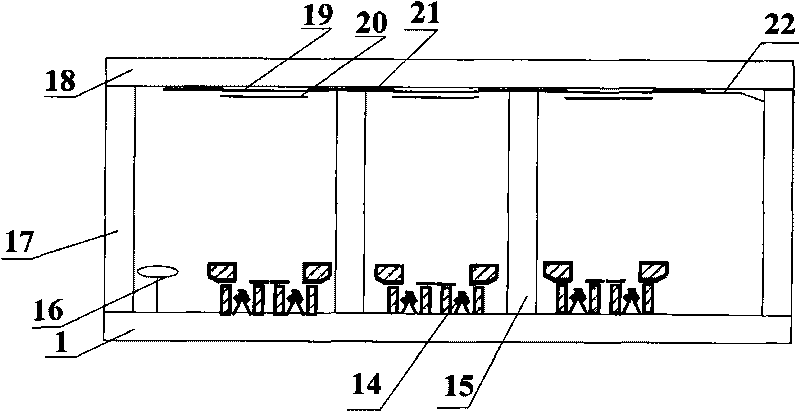

[0044] Such as figure 1 , 2 , 3, the present invention includes a sealed vacuum chamber made of cathode glass panel 1, anode glass panel 18 and glass enclosure 17; Layer 21 and the phosphor layer 20 prepared on the anode conductive layer 19; the partition wall 15 and the getter 16 between the anode glass panel 18 and the cathode glass panel 1; it is characterized in that:

[0045] The cathode glass panel 1 is provided with a right-angle bent pair-group grid-controlled cathode structure; the base material of the right-angle-bend pair-group grid-controlled cathode structure is a cathode glass panel; the insulating paste printed and sintered on the cathode glass panel is formed Cathode isolation layer; there is a cathode conductive layer on the cathode isolation layer, and the cathode conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com