Embedded nut for connecting overlapping elements

A technology of pre-embedded nuts and lap joints, applied in the direction of connecting components, nuts, threaded fasteners, etc., can solve the problems of inability to use bolts and nuts, safety, unsuitable space for tightening operations, connections, etc., to achieve safety and efficiency Installation work, high work efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

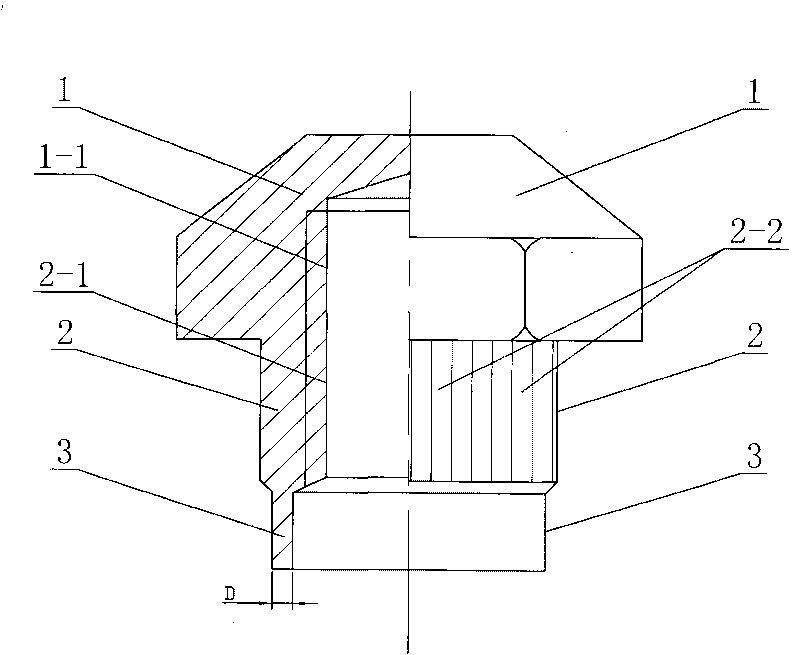

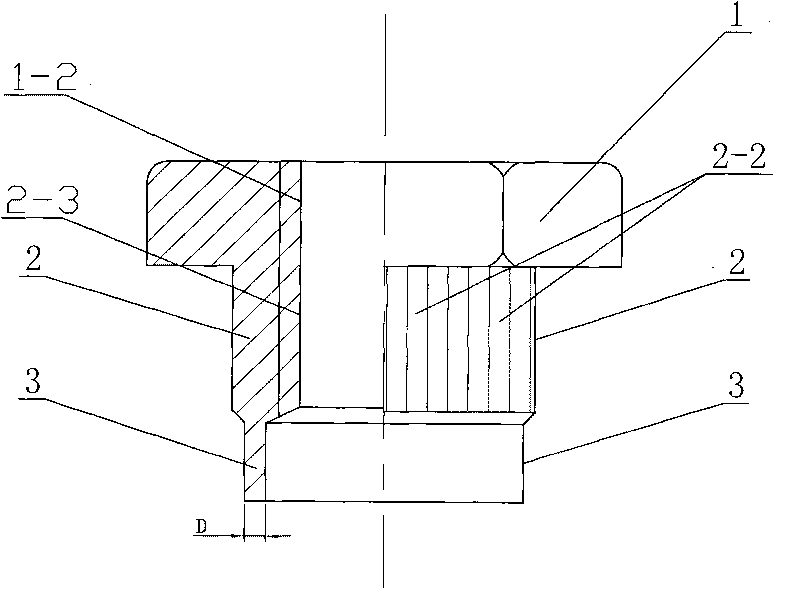

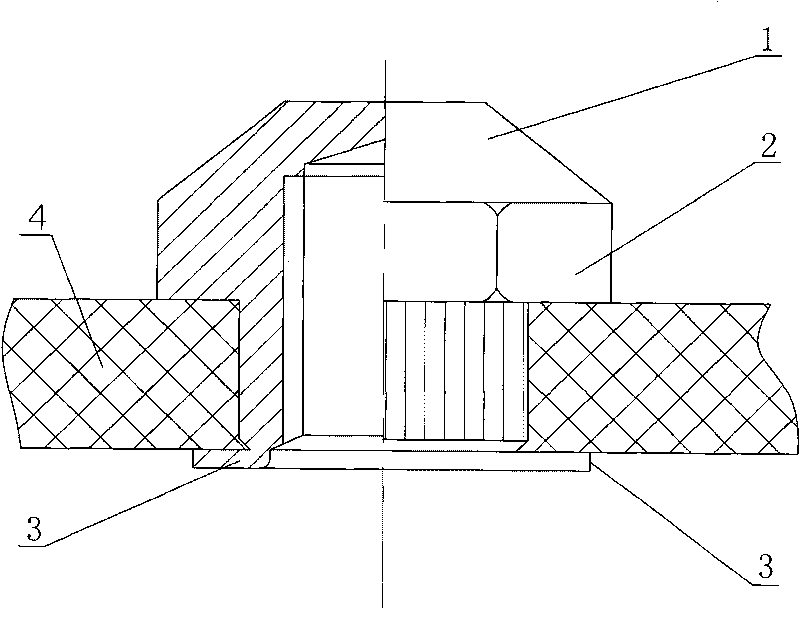

[0009] Specific implementation mode one: as figure 1 As shown, the pre-embedded nut used to connect the bridge piece in this embodiment is composed of a nut 1, a nut body 2 and a locking flange 3, and the nut 1, the nut body 2 and the locking flange 3 are along the axis The direction is fixed in sequence, the inside of the nut 1 is provided with a threaded blind hole 1-1 along the axis direction, and the inside of the nut body 2 is provided with a first threaded through hole 2-1 along the axis direction. The blind hole 1-1 is coaxial with the first threaded through hole 2-1, the threaded blind hole 1-1 communicates with the first threaded through hole 2-1 and the diameter of the threaded hole is equal, and the lateral diameter of the locking edge 3 The section is circular, and the diameter of the locking edge 3 is larger than the diameter of the first threaded through hole 2-1. The nut 1 is provided with a threaded blind hole 1-1, which avoids the exposure of the bolt hole an...

specific Embodiment approach 2

[0010] Specific implementation mode two: as figure 1 As shown, the outer surface of the nut body 2 in this embodiment is provided with a plurality of anti-rotation grooves 2-2 along the axial direction. With this design, the nut body 2 is in interference fit with the mounting hole during installation, preventing the embedded nut from rotating together with the bolt when the bolt is tightened. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: as figure 1 As shown, the cross section of the nut 1 in this embodiment is a regular hexagon. With such a design, a wrench can be used to fix the embedded nut when the anti-rotation groove 2-2 fails, so as to prevent the embedded nut from rotating. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com