Preparing method of Sr(0H)2.8H2O

A technology of strontium hydroxide and solution, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve problems such as lack of competitiveness, and achieve the effect of reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

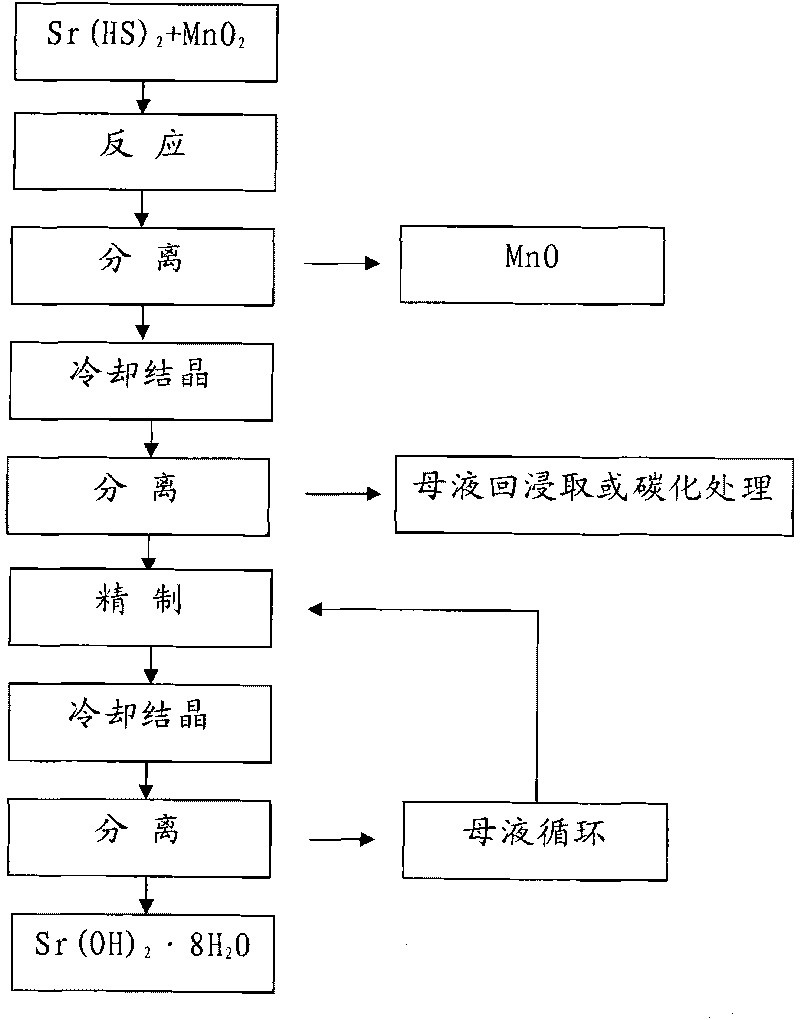

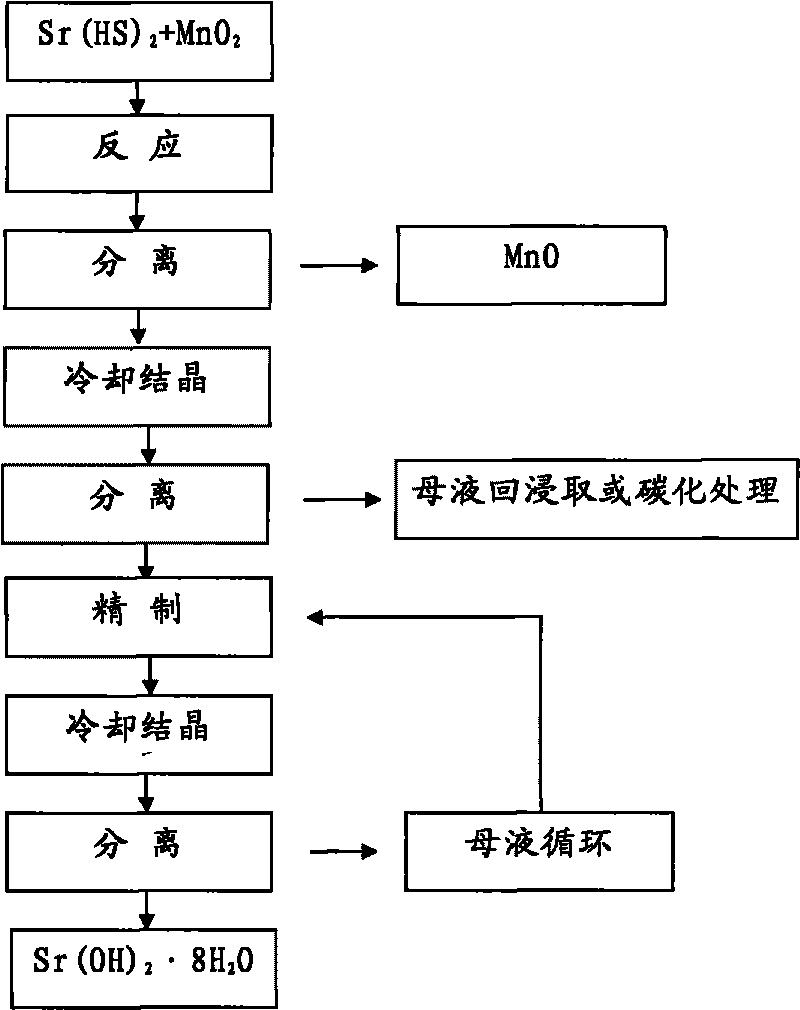

Method used

Image

Examples

Embodiment 1

[0014] 0.47mol / L of Sr(HS) 2 Solution 4000ml is placed in the 5000ml beaker, adds 752g manganese oxide ore powder (MnO 2 25.1%, Fe 7.8%), heated in an electric furnace and maintained at 70 ° C, sealed and stirred for 2 hours, stopped stirring, after settling, use a latex tube to absorb the supernatant, add 1000ml hot deionized water and stir to wash after the reaction, and then separate by suction filtration , the residue was prepared from MnSO 4 Products, combined filtrates, sealed and cooled to 35 ° C.

[0015] After the above cooling, the solution is suction filtered and separated, and the filtrate is carbonized to recover SrCO 3 , crude Sr(OH) 2 ·8H 2 O according to 0.8mol / L [Sr 2+ ] Add deionized water and heat to dissolve, add 27.5% H at a ratio of 3ml / L 2 o 2 Remove sulfur, heat to boil and maintain boiling for 15 minutes, filter with slow qualitative filter paper, discard the filter residue, and cool the filtrate to 40°C.

[0016] Centrifuge the above cooled so...

Embodiment 2

[0018] 0.55mol / L Sr(HS) 2 Solution 4000ml is placed in the 5000ml beaker, adds 628g manganese oxide ore powder (MnO 2 38.7%, Fe 8.6%), heated in an electric furnace and maintained at a temperature of 80°C, closed reaction for 2 hours, stopped stirring, siphoned the supernatant after settling, added 1000ml hot deionized water to dilute and washed the residue, separated by suction filtration, and prepared the filter residue MnSO 4 , and the combined filtrates were sealed and cooled to 30°C.

[0019] After the above cooling, the solution is suction filtered and separated, and the filtrate is carbonized to recover SrCO 3 , crude Sr(OH) 2 ·8H 2 O by 0.7mol / L [Sr 2+ ] Dissolve with hot deionized water, add 3ml / L 27.5% H 2 o 2 Remove sulfur, heat to boil, and maintain for 25 minutes, filter with slow qualitative filter paper, discard the filter residue, and cool the filtrate to 45°C.

[0020] The above-mentioned cooled solution is centrifuged, and the mother liquor is recycle...

Embodiment 3

[0022] 0.40mol / L Sr(HS) 2 Solution 4000ml is placed in the 5000ml beaker, adds 474g manganese oxide ore powder (MnO 2 38.7%, Fe 8.6%), heated in an electric furnace and maintained at a temperature of 85°C, closed reaction for 2 hours, stopped stirring, siphoned the supernatant after settling, added 1000ml hot deionized water to dilute and washed the residue, separated by suction filtration, and prepared the filter residue MnSO 4 , and the combined filtrates were sealed and cooled to 32°C.

[0023] After the above cooling, the solution is suction filtered and separated, and the filtrate is carbonized to recover SrCO 3 , crude Sr(OH) 2 ·8H 2 O according to 0.7mol / L [Sr 2+ ] Dissolve with hot deionized water, add 3ml / L 27.5% H 2 o 2 Remove sulfur, heat to boil, and maintain for 25 minutes, filter with slow qualitative filter paper, discard the filter residue, and cool the filtrate to 43°C.

[0024] The above-mentioned cooled solution is centrifuged, and the mother liquor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com