Belt driving device of online detection device

A technology of belt transmission and testing equipment, applied in measuring devices, transportation and packaging, instruments, etc., can solve the problems of cumbersome sampling inspection, inability to comprehensively and effectively control product quality, and affect product testing, etc., and achieve good transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

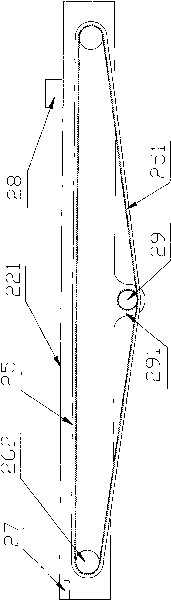

[0013] like figure 1 The belt transmission device for online detection equipment shown includes an adjustment loading platform 221 and rollers 262 arranged at both ends of the adjustment loading platform 221. The outer surface of the roller 262 is provided with a concave drive belt 25, and its characteristic It is: grooves 251 are evenly arranged on the inner surface of the concave strip transmission belt 25, a gear bearing 291 is arranged under the middle part of the adjustment loading platform 221, and the gear shaft 29 is connected with the gear bearing 291. The surface of the gear shaft 29 is in gear contact with the inner side of the grooved drive belt 25, the grooved drive belt 25 and the groove 251 are elastic, and the other end of the gear shaft 29 is connected to the transmission device.

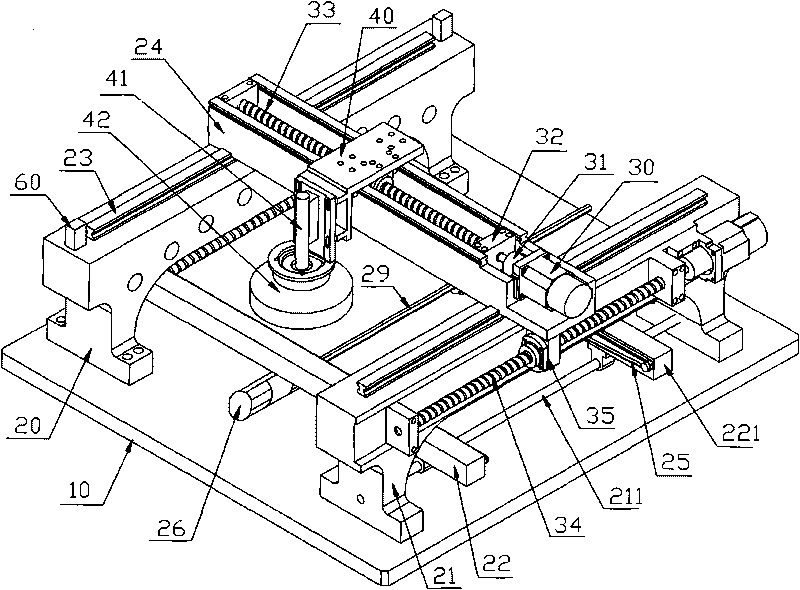

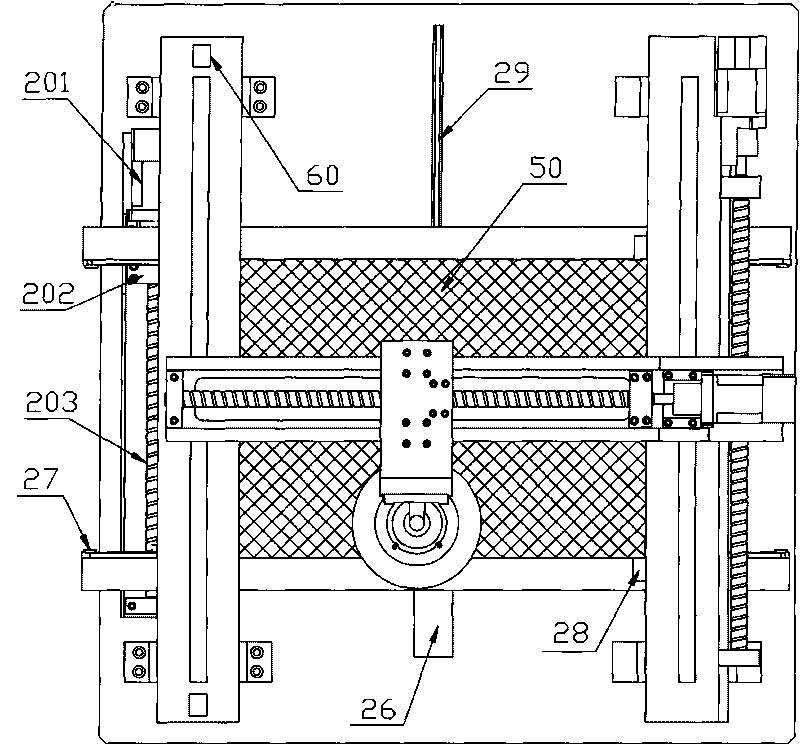

[0014] like figure 2 , image 3 As shown, an entrance arch bridge seat 20 and an exit arch bridge seat 21 are arranged in parallel on both sides of the base 10, and a guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com