Aluminum shell of track compartment air conditioning unit

A technology for air-conditioning units and shells, which is applied to railway car body parts, railway vehicle heating/cooling, transportation and packaging, etc., which can solve the high cost of rail car manufacturing, installation and transportation, and does not meet the development requirements of rail cars , high design requirements and other issues, to achieve the effect of weight reduction, light body weight and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the aluminum casing of the rail car air-conditioning unit of the present invention are given below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to the following embodiments.

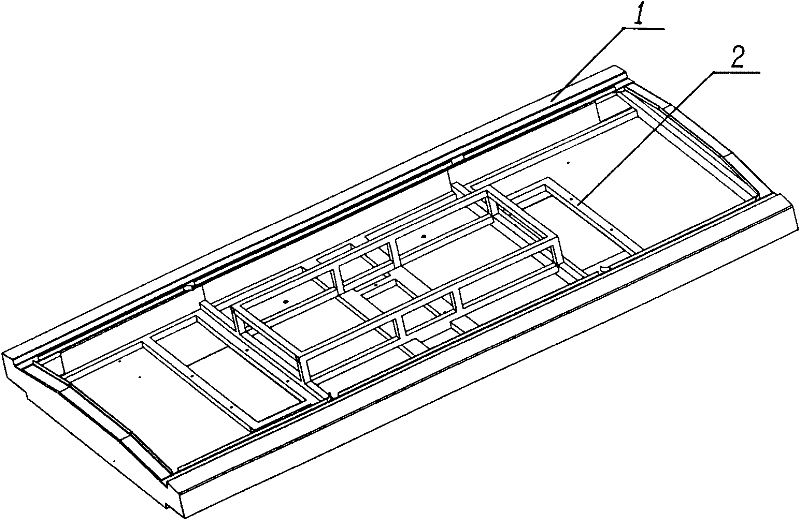

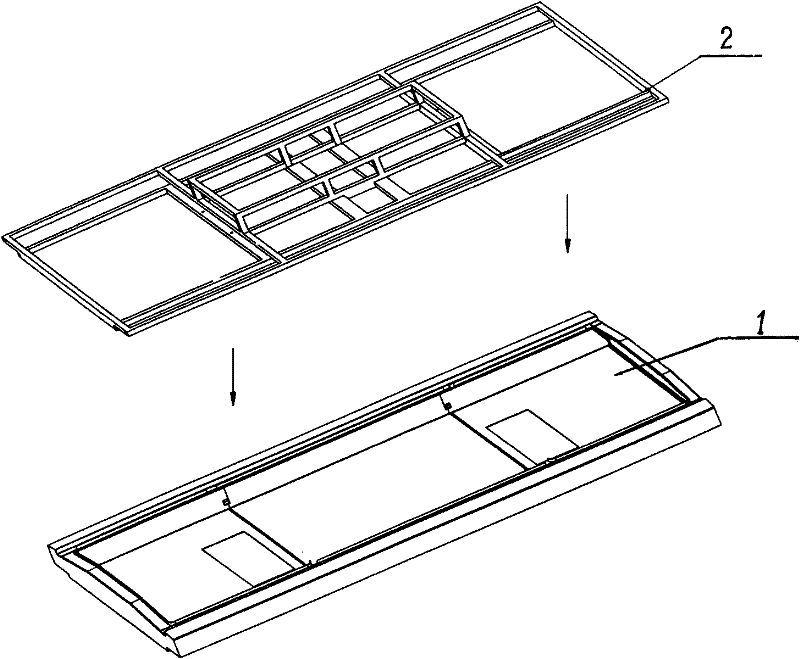

[0033] See attached figure 1 with 2 .

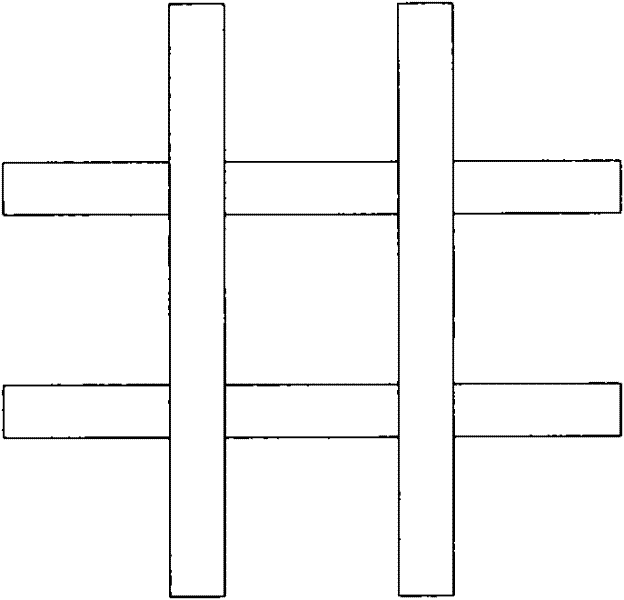

[0034] An aluminum shell of an air-conditioning unit in a rail car, all made of aluminum alloy materials, adopts an aluminum alloy square tube 4 with a reinforcing protrusion 5 in the tube cavity (see attached Figure 4 ) or an aluminum alloy rectangular tube as a pipe material to manufacture the aluminum profile skeleton 2, the aluminum alloy square tube 4 with the reinforced protrusion 5 is not only well formed, not easy to bend and deform, but also ensures the proper strength of the frame after the aluminum alloy profile is welded; adopt the aforementioned Aluminum alloy pipes and aluminum alloy plates are used to manufacture aluminum shell structural parts 1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap