Rotational cutting tool state multiple parameter overall assessment method based on image identification

A technology for comprehensive evaluation of rotating tools, applied in manufacturing tools, measuring/indicating equipment, instruments, etc., which can solve the problem that the dynamic measurement of tools cannot be achieved, the depth of tool surface wear cannot be obtained, and the multi-parameter comprehensive evaluation method of the state of rotating tools has not yet been found. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments are provided in conjunction with the accompanying drawings and the content of the method of the present invention:

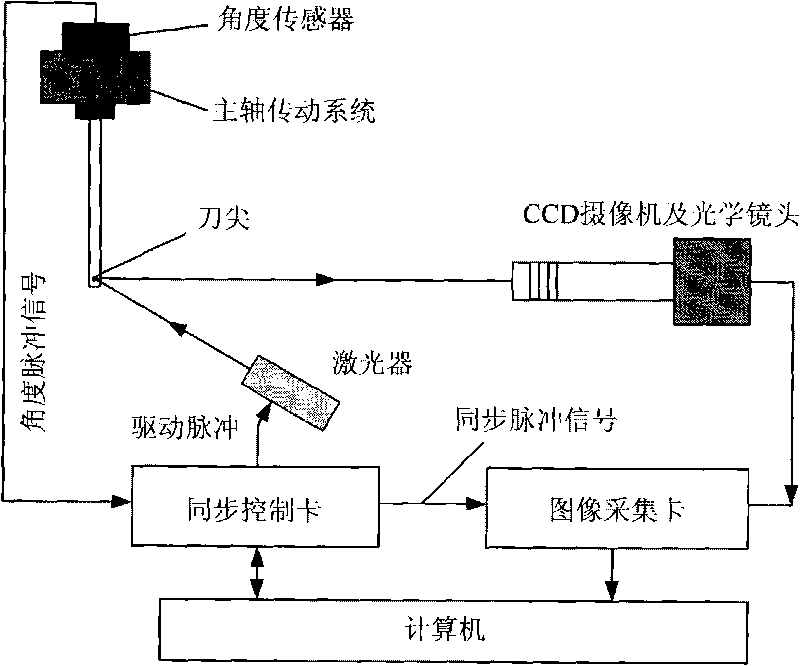

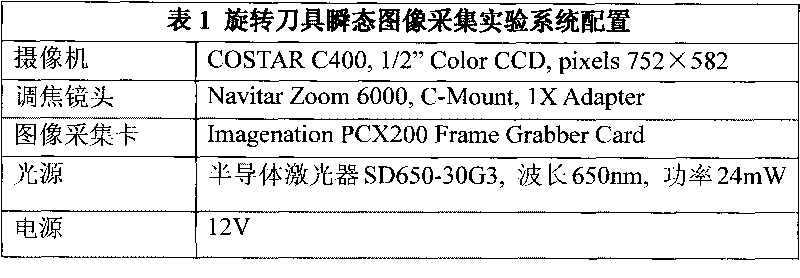

[0017] This embodiment is carried out on the domestic VMC850 vertical machining center, and the tool to be tested is a special boring tool for the machining center produced in Germany. The hardware configuration of the image measurement system is shown in Table 1, and the basic structure is shown in Figure 1, mainly including optical imaging system: CCD camera, focusing lens, laser light source, etc.; mechanical motion system: tool, workpiece and its spindle drive control device ; Image acquisition system: image acquisition card, angle sensor, synchronous control card and computer, etc. According to the composition principle in Figure 1, during the gap between loading and unloading of the workpiece or retracting the tool (the spindle is still in a high-speed rotation state), the transient image of the boring tool at a fixed angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com