Large vibration table

A vibrating table, large-scale technology, applied in the field of large-scale vibrating tables, can solve problems such as technical level, uneven quality, strong vibration, impact, environmental problems, etc., achieve vibration environmental problems improvement, high excitation frequency, and facilitate sand falling cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

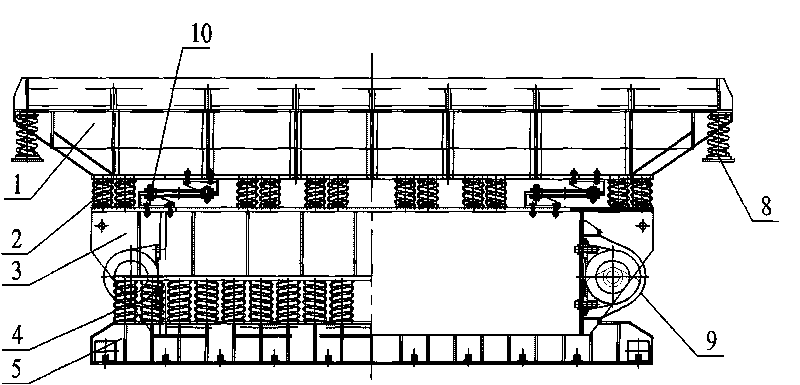

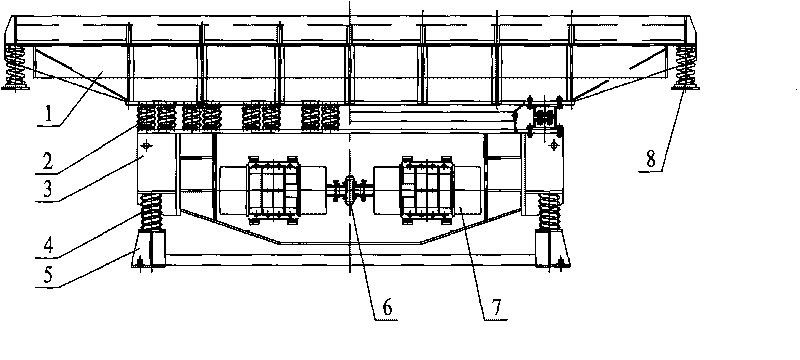

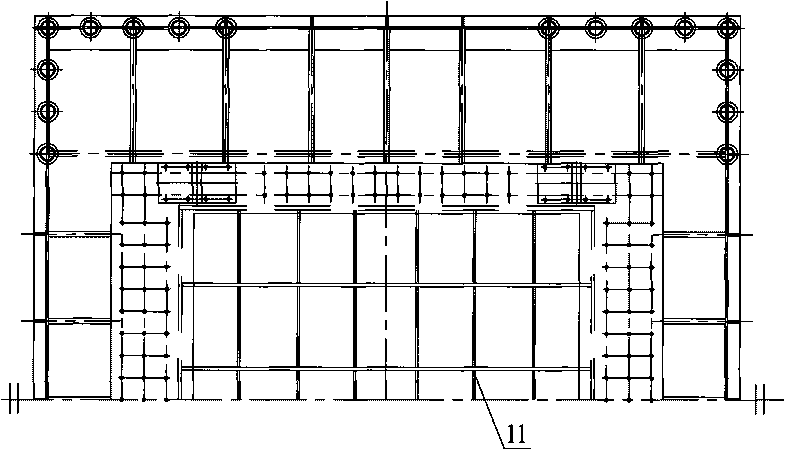

[0021] As shown in the figure, the present invention mainly consists of a vibrating table 1, an exciting spring 2, an exciting body 3, a damping spring 4, a base 5, a universal coupling 6, a vibrating motor 7, a supporting spring 8, a vibrating motor protective cover 9, The elastic damper 10 is composed.

[0022] like figure 1 As shown, the base 5 is fixed on the ground or the work platform by bolts, the damping spring 4 is installed on the base 5, the vibration exciter 3 is installed on the damping spring 4, the vibration motor 7 is installed on both sides of the vibration excitation body 3, and the vibration motor There are four sets of vibration motors 7 in total, and every two vibration motors 7 are connected in series with a universal coupling 6, which are respectively installed on the two ends of the frame body of the excitation body 3, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com