Piezoelectric valve

A piezoelectric valve, pre-compression technology, applied in valve detail, valve device, valve operation/release device, etc., can solve problems such as closing force reduction, flow power limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

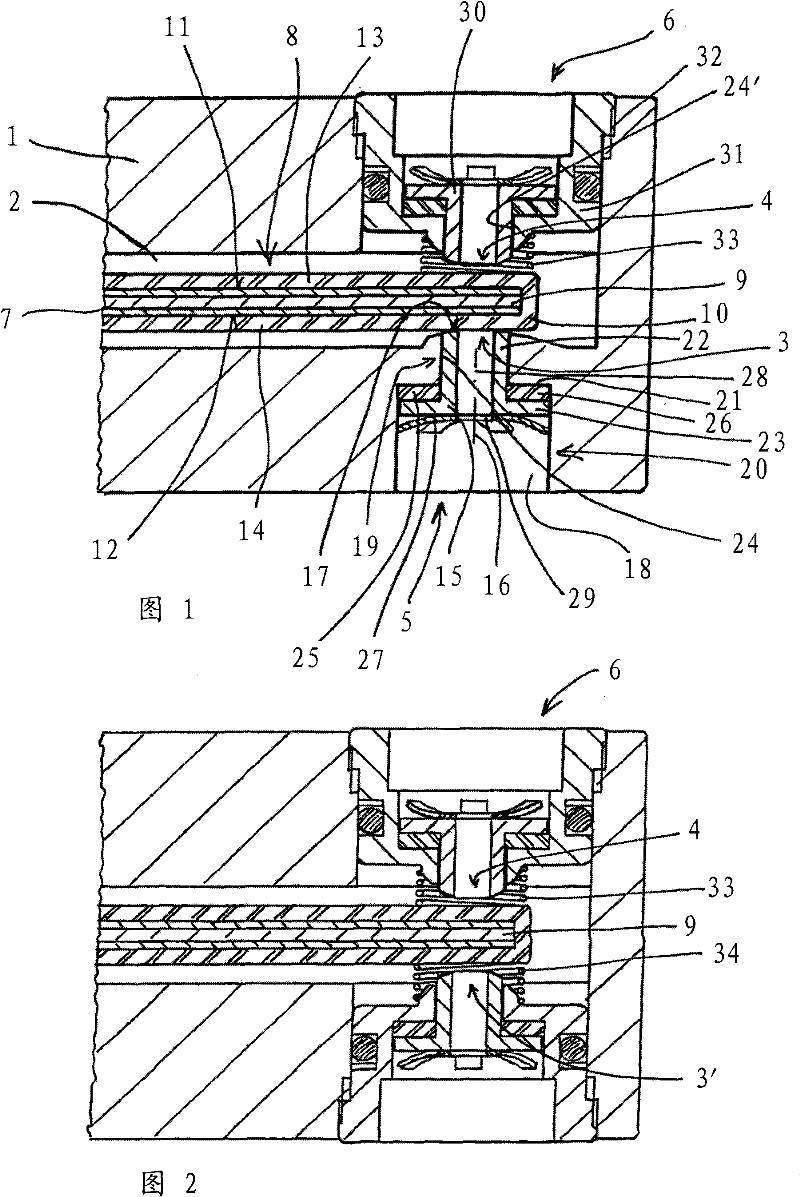

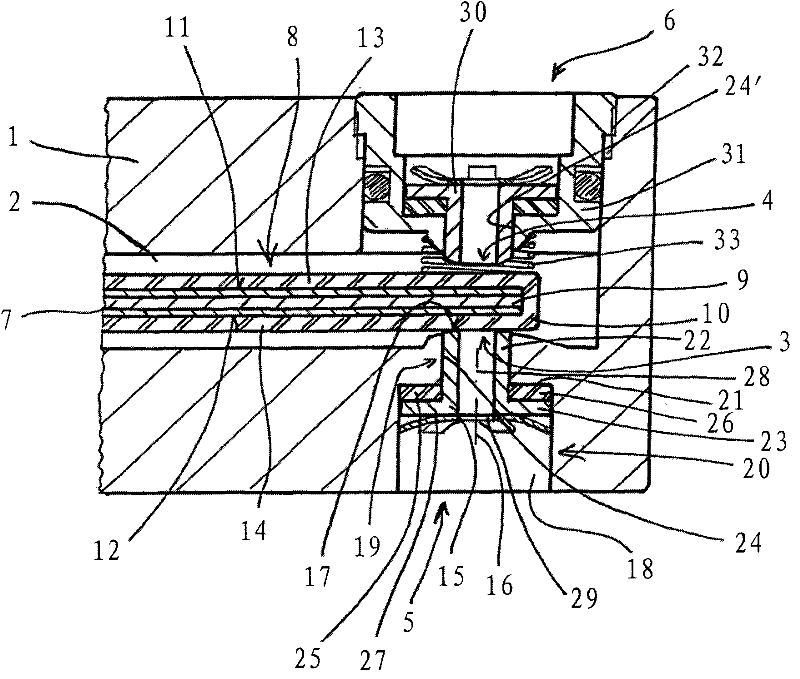

[0014] In terms of its basic structure, the figure 1 The piezo valve shown in the preferred embodiment corresponds to the piezo valve disclosed in EP 943812 A1 (US 6143744 B1). Therefore, a description of the piezoelectric valve in its entirety and the remaining design features is omitted, but full reference is made to the aforementioned publications in order to supplement the following explanation.

[0015] figure 1 The piezo valve shown in includes a housing 1 with an inner space 2 through which flow can flow. Two mutually opposite nozzles 3 and 4 open into the interior 2 , each communicating with an associated fluid medium connection 5 or 6 . Furthermore, the interior 2 of the housing 1 communicates in a known manner with an opening (not shown). In said inner cavity 2 of the housing 1 is mounted a piezoelectric bending element 7 deformable by energization such that one of the piezoelectric elements 7 changes its position relative to the housing when energized The region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com