Electrode terminal connection structure and power battery pack using same

An electrode terminal and connection structure technology, applied in the field of electrode terminal connection structure, can solve the problems such as reliability affecting the popularization of electric vehicles, rigid connection structure susceptible to impact, and inability to quickly achieve fusing, etc. Reliability, the effect of optimizing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

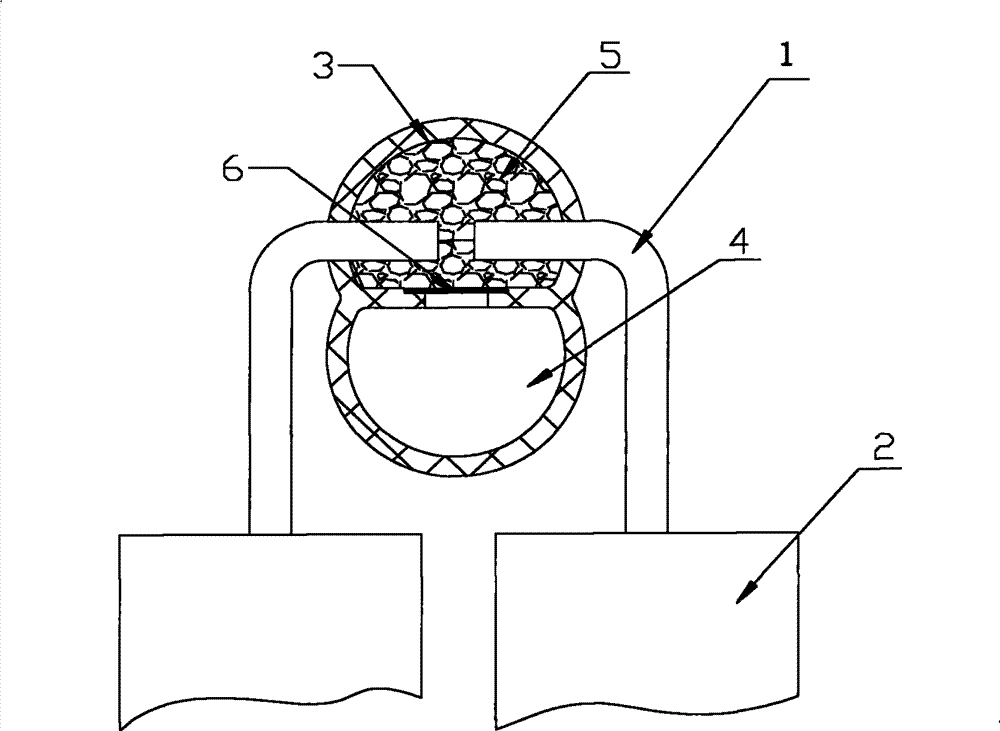

[0036] The traditional electrode terminal connection structure such as Figure 9 As shown, the electrode terminals 1 are filled with a solid conductive medium 5, and through rigid connection, different electrode terminals 1 are electrically connected. As mentioned above, this kind of rigid connection cannot guarantee the reliability of the connection of the electrode terminal 1. When this electrode terminal connection structure is applied to the power battery pack of the car, various shaking, vibration, Even in a collision, the rigid connection structure between the electrode terminals 1 is easily damaged by impact, thereby loosening and disconnecting, causing the power battery pack to fail to work, and the electric vehicle to be unable to drive. Therefore, in the prior art, the electrode terminal connection structure The reliability is a more prominent shortcoming.

[0037] In this prior art, when the current increases, since the current conduction capability of the conducti...

specific Embodiment approach 1

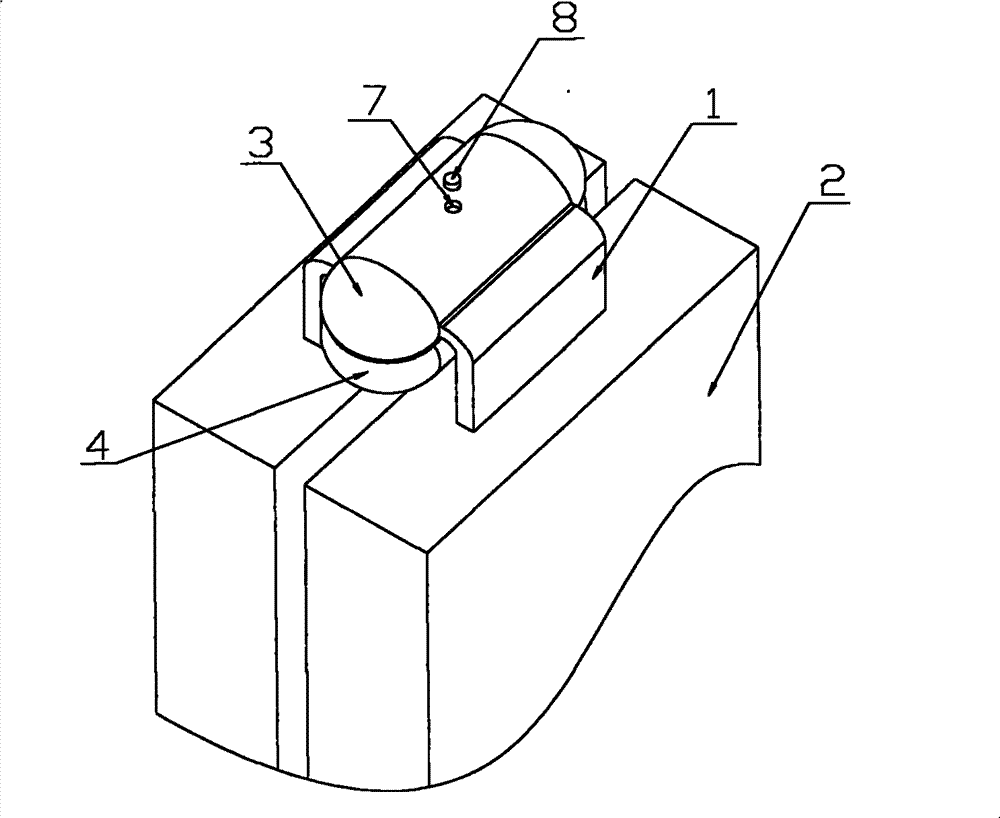

[0039] This embodiment is an embodiment in which the electrode terminal 1 is located on the upper surface of the power battery pack during operation of the power battery pack.

[0040] Such as Figure 1 to Figure 4 As shown, the electrode terminal 1 is sealed and connected by the conductive cavity 3, the collecting cavity 4 is arranged under the conductive cavity 3, the lower side of the conductive cavity 3 is provided with an opening, and is separated from the collecting cavity 4 by a separator 6, from the conductive cavity 3 A conductive medium 5 is added to the conductive medium addition hole 7 above, and finally the sealing plug 8 is sealed to the conductive medium additive hole 7 .

[0041]Wherein, the melting temperature of the separator 6 is 100°C-350°C, so that the electrode terminal connection structure can be melted when the overheating temperature reaches 100°C-350°C. Of course, the melting temperature of the separator 6 can also be determined according to the actua...

specific Embodiment approach 2

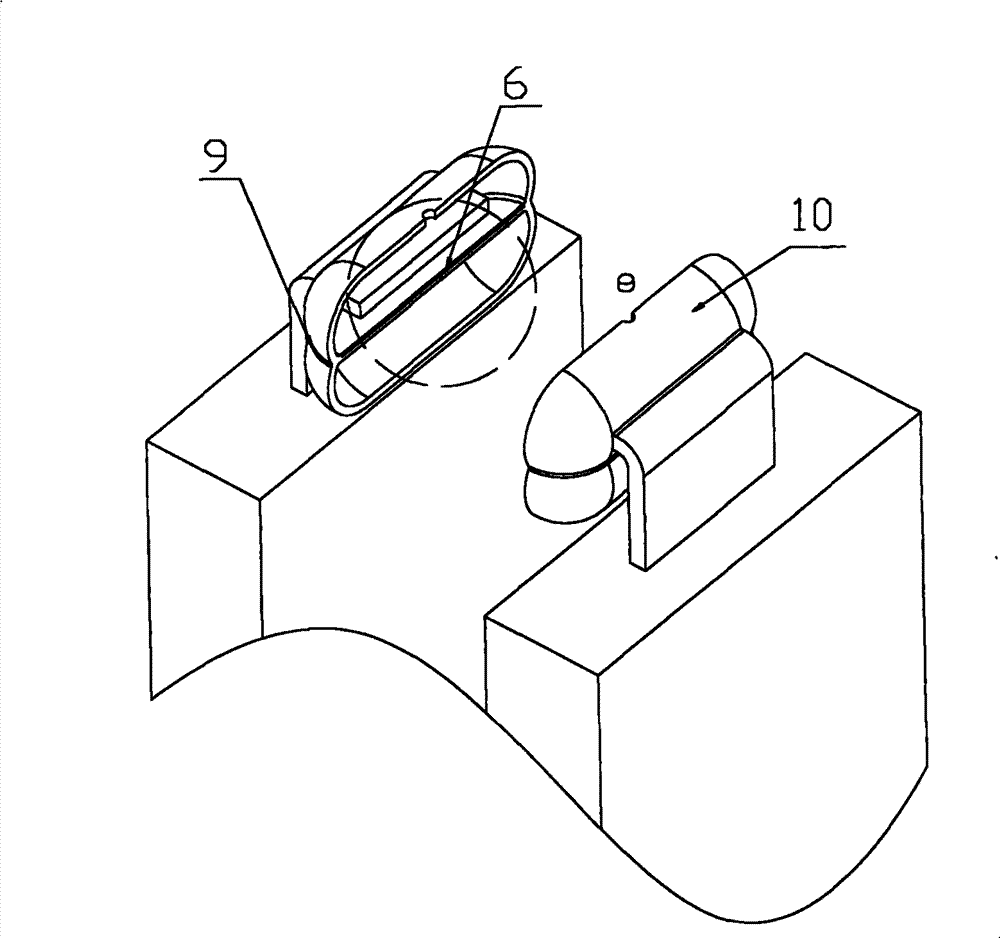

[0050] This embodiment is an embodiment in which the electrode terminal 1 is located on the side of the power battery pack during operation of the power battery pack.

[0051] Such as Figure 5 to Figure 8 As shown, the electrode terminal 1 is sealed and connected by the conductive cavity 3, and the collecting cavity 4 is arranged under the conductive cavity 3. 7 Add the liquid conductive medium 5, and finally seal the sealing plug 8 on the conductive medium additive hole 7.

[0052] When the current increases, the heat generated by the liquid conductive medium 5 is greater, and the temperature rises rapidly. When the temperature rises to a certain level, the separator 6 melts, and the conductive medium 5 flows from the conductive cavity 3 to the collection cavity 4, so that the electrodes There is no liquid conductive medium 5 between the terminals 1, and the circuit is disconnected, which prevents further thermal response and avoids thermal runaway.

[0053] It can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com