Pad connecting structure, lead wire jointing structure and encapsulating structure

A technology of packaging structure and pad structure, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as stress concentration, peeling of bonding wire 910 and pad 920, damage and deformation, and reduce damage or Deformation, reduce peeling problems, and ensure the effect of bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

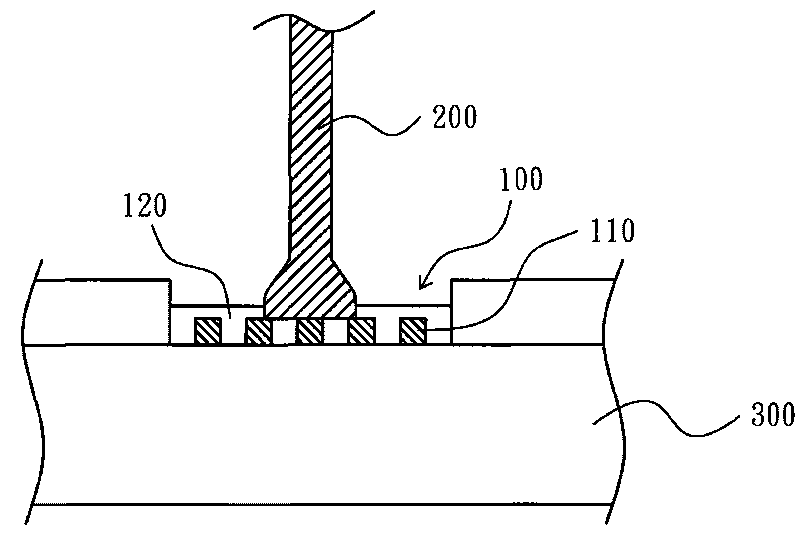

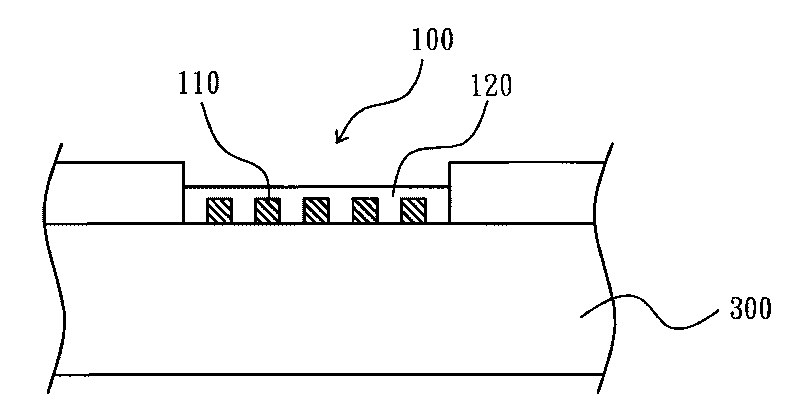

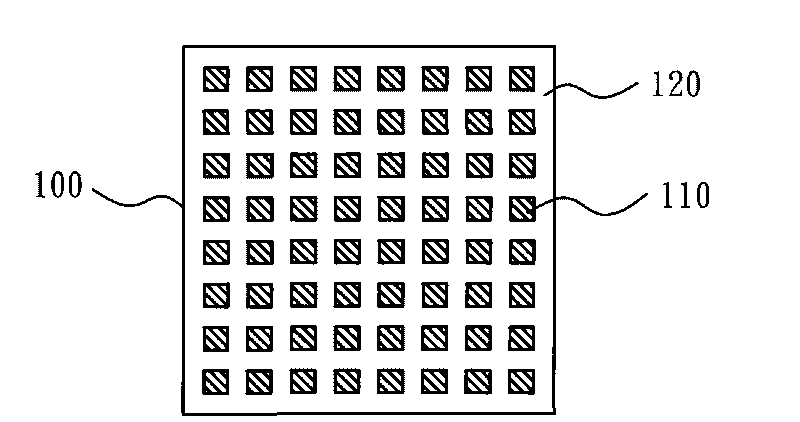

[0028] Please refer to figure 1 , which shows a schematic cross-sectional view of a wire bonding structure according to an embodiment of the present invention. The pad structure 100 of this embodiment is used to bond (eg solder) the wire 200 to form a wire bonding structure, which can be applied in a packaging structure for electrical connection. The pad structure 100 includes a patterned structure 110. The patterned structure 110 has a first material whose hardness is greater than that of the wire 200, and the distribution area of the patterned structure 110 in the pad structure 100 is larger than that of the wire 200 and the wire. The contact area between the pad structures 100 (that is, the area of the bonding surface) is used to prevent the pad from being damaged or deformed by being pressed by the wire when the hardness of the wire is greater than that of the pad.

[0029] Please refer to Figure 2 to Figure 3E , figure 2 A schematic cross-sectional view showing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com