Magnetic-shielding eddy current sensor probe and method for reducing eddy current effect

An eddy current sensor and magnetic shielding technology, which is applied in the field of eddy current sensors and magnetically shielded eddy current sensor probes, can solve the problems that affect the wide application of magnetic shielded eddy current sensor probes, the large size of the magnetic shielding sleeve, and the drop in the Q value of the measuring coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

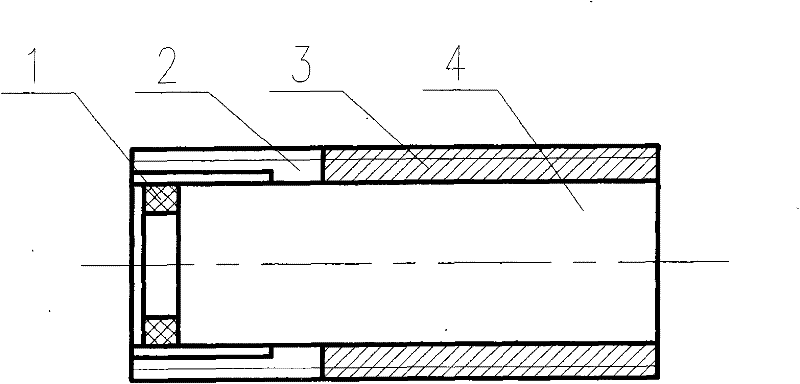

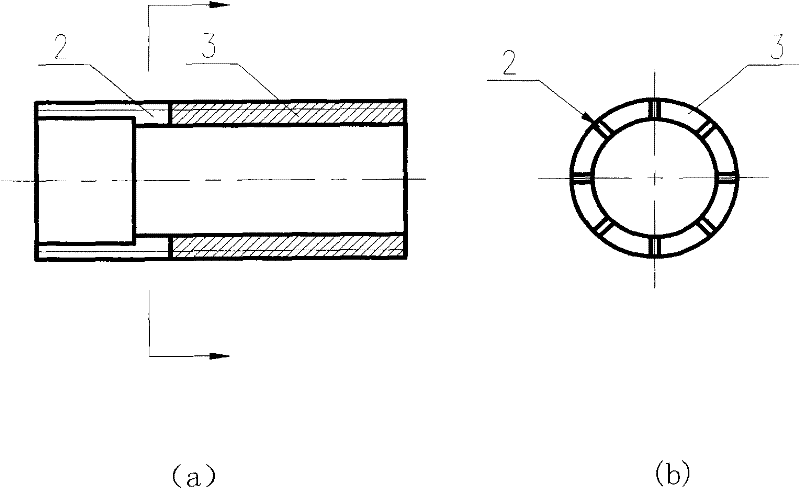

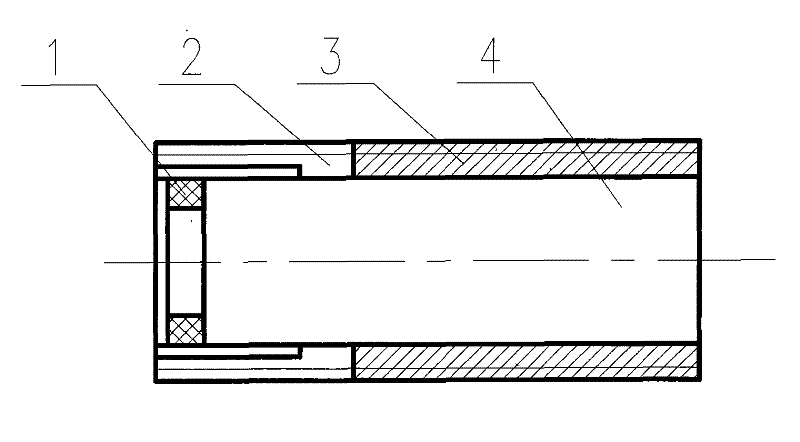

[0011] The composition, working principle and structural design of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] In the present invention, the measuring coil of the eddy current sensor is placed in a magnetic shielding sleeve made of a soft magnetic alloy material, which will not cause a significant decline in the Q value of the measuring coil (Q=XL / R, where XL represents inductive reactance, and R Indicates the resistance), and will not significantly increase the size of the eddy current sensor probe, the core of which lies in the design of the magnetic shielding sleeve. The invention designs and processes 1-100 slits in the axial direction of the circumference of the magnetic shielding sleeve, the width of the slits is 0.02-10mm, and the depth of the slits along the axial direction is 0.2-100 times the outer diameter of the measuring coil. Although the eddy current sensor probe will also induce eddy cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com