Stick for measuring circumferential distance of flange plate

A technology for measuring rods and spacing, which is applied in the direction of mechanical clearance measurement, etc., can solve the problems of increasing divers' underwater operation time, difficulty in placing calipers in place accurately, leakage at flange joints, etc., to achieve accurate and fast measurement, simple structure, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

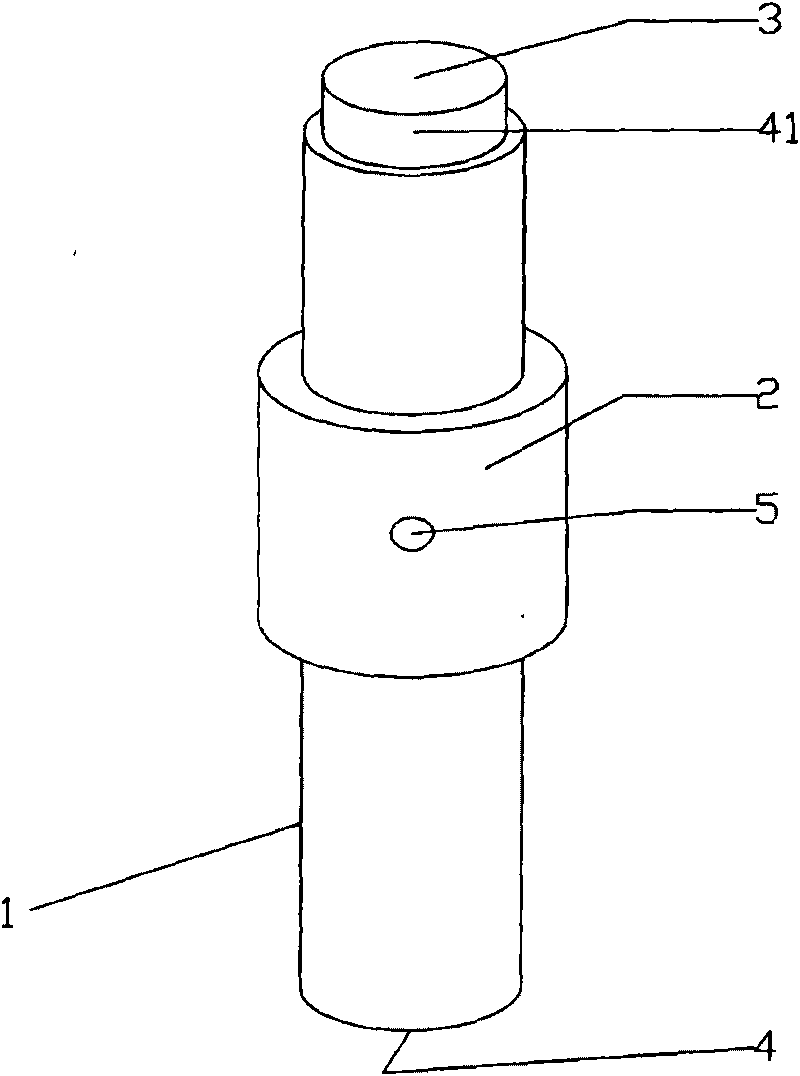

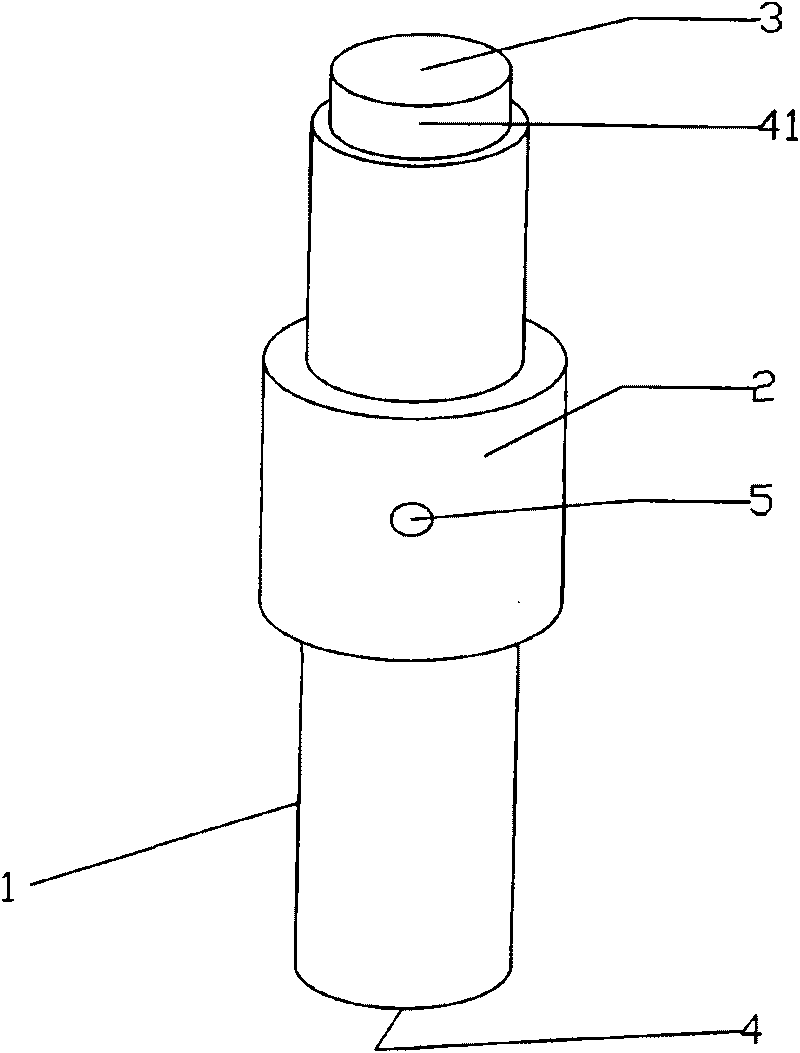

[0017] Embodiment one (see figure 1 shown):

[0018] Prepare 3# measuring rod, adopt copper processing rod body 1, the cross section of rod body 1 is circular, and length is 73MM; The diameter of the hole 5 is 5 mm; the diameter of one side of the middle part of the rod body 1 is 16 mm, and a measurement scale 3 is set at the end of this side, and the scale value of the scale 3 is 16 mm, which is printed by hammering; the middle part of the rod body 1 The diameter of the other side is 15mm, and the measuring scale 4 is set at the end of this side, and the scale value of the scale 4 is 15mm, which is printed by hammering; and a boss 41 is integrally formed on the top of the measuring scale 4, the boss 41 has a height of 4 mm, a diameter of 11 mm, and a circular cross-section.

Embodiment 2

[0019] Embodiment two (see figure 1 shown):

[0020] Prepare 2# measuring rod, adopt copper material to process rod body 1, the cross section of rod body 1 is circular, and length is 83MM; The diameter of the hole 5 is 5 mm; the diameter of one side of the middle part of the rod body 1 is 18 mm, and the measuring scale 3 is set at the end of this side, and the scale value of the scale 3 is 18 mm, which is printed by hammering; the other part of the middle part of the rod body 1 The diameter of one side is 17mm, and a measurement scale 4 is set at the end of the side. The scale value of the scale 4 is 17mm, which is printed by hammering; and a boss 41 is integrally formed on the top of the measurement scale 4, and the boss 41 41 has a height of 5 mm, a diameter of 13 mm, and a circular cross-section.

Embodiment 3

[0021] Embodiment three (referring to figure 1 shown):

[0022] Prepare 1# measuring rod, adopt copper material to process rod body 1, the cross section of rod body 1 is circular, and length is 93MM; The diameter of the hole 5 is 5 mm; the diameter of one side of the middle part of the rod body 1 is 20 mm, and the measuring scale 3 is set at the end of this side, and the scale value of the scale 3 is 20 mm, which is printed by hammering; the other part of the middle part of the rod body 1 The diameter of one side is 19 mm, and a measurement scale 4 is set at the end of the side. The scale value of the scale 4 is 19 mm, which is printed by hammering; The height is 6mm, the diameter is 15mm, and the cross section is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com