Dual-membrane micro-resistant ultrashort backflow preventer

A backflow preventer and diaphragm technology, applied in the direction of control valves, functional valve types, engine components, etc., can solve the problems of water supply safety hazards, easy loss, long structure, etc., to save installation space, ensure water supply safety, and low water head. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure of the double-diaphragm micro-resistance ultra-short backflow preventer of the present invention without an external catheter is described in conjunction with the accompanying drawings and embodiments.

[0010] The double-diaphragm micro-resistance ultra-short backflow preventer is a structure with a major breakthrough in the technical field.

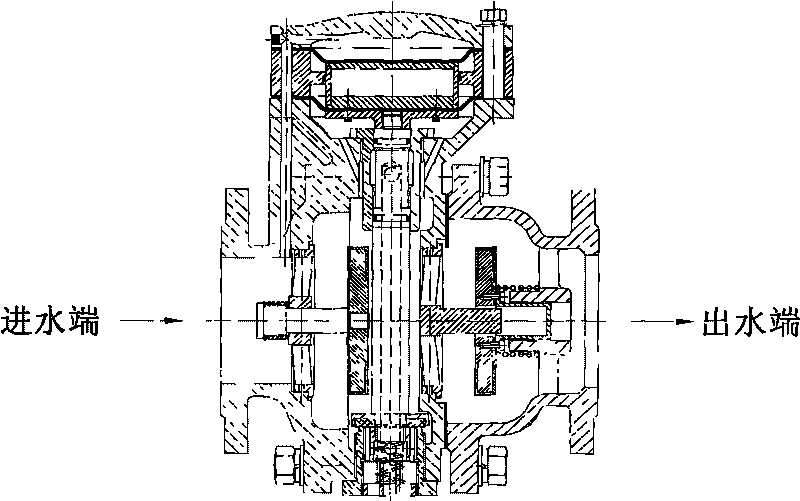

[0011] Such as figure 1 as shown, figure 1 The middle arrow indicates the direction of medium flow. During normal water supply, the double-diaphragm micro-resistance ultra-short backflow preventer, the pressure water will open the check valve plate one (7) and the check valve plate two (20) to the right successively under the action of pressure water, and the water inlet The water enters the upper cavity of the control room through the through hole on the drain valve body (11) and through the through hole of the interlayer sleeve (15), so that no other external parts are needed to guide the water from the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com