The method of rebuilding the diversion tunnel into a flood discharge tunnel by using the combined orifice energy dissipation technology

A technology of diversion tunnels and combined holes, which is applied in construction, water conservancy projects, sea area projects, etc., can solve the problems of insufficient energy dissipation, large discharge flow, increased cavitation cavitation, and high energy dissipation requirements, so as to avoid cavitation, Improvement of cavitation characteristics and improvement of energy dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

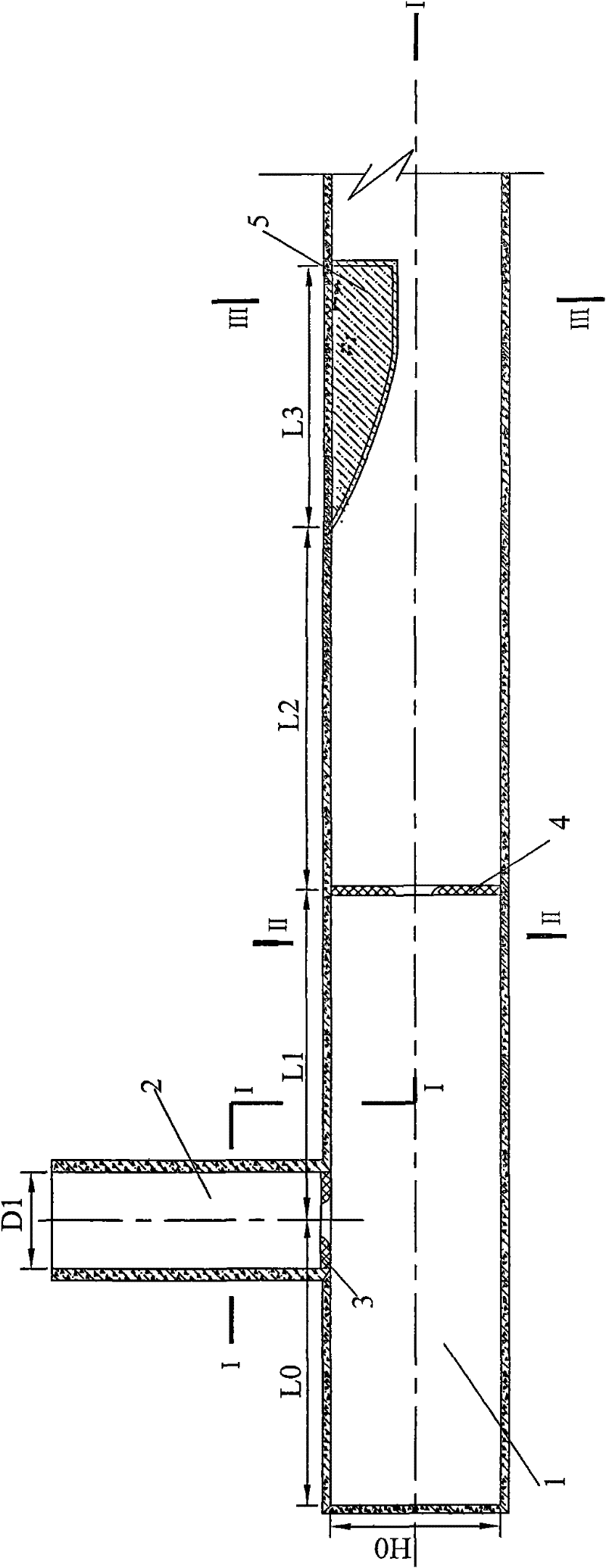

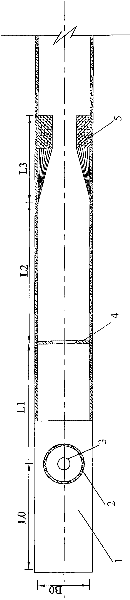

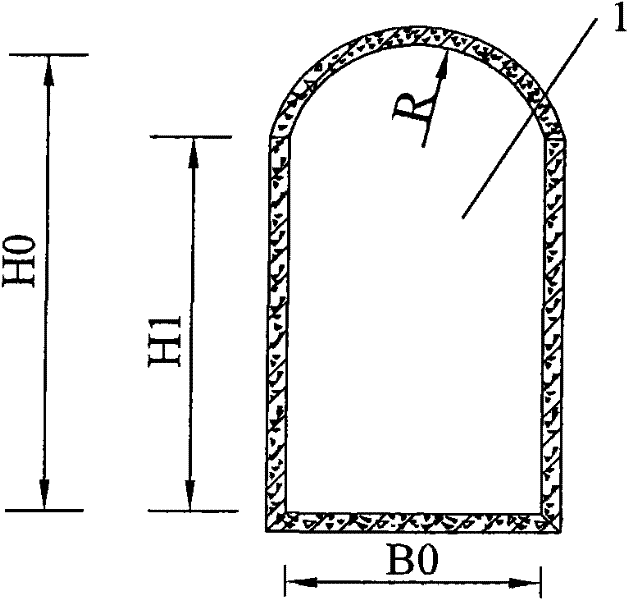

[0035] The water retaining structure of a water conservancy project adopts a concrete gravity dam, the maximum dam height is 204m, and the maximum flood discharge discharge of the project is about 13927m 3 / s (peak flow is 14800m 3 / s), the total flood discharge power is 11600MW, the maximum single-width discharge exceeds 124m / s, the installed capacity is 1600MW (4×400MW), and the discharge capacity of the flood discharge tunnel is 1300m 3 / s, has the characteristics of narrow river valley, high water head, large flow and high velocity. Reconstruction section 1 of diversion tunnel is in the shape of "city gate hole", width B0=16.0m, height H0=20.0m, height of straight wall section H1=16m, radius of vault R=3.5m. The operation of rebuilding the diversion tunnel by adopting the method of the present invention is as follows:

[0036] ① A vertical shaft 2 connected to the diversion tunnel is set at the closed end of the diversion tunnel reconstruction section 1. The shaft is cir...

Embodiment 2

[0042] The barrage of a hydropower station is a concrete face rockfill dam, the maximum dam height is 146m, the normal water storage level is 998.00m, and the adjusted storage capacity is 0.83×108m 3 (The adjustment characteristic is seasonal adjustment, the storage capacity coefficient is 0.021), and the installed capacity is 240MW. 3 / s. The reconstruction section 1 of the diversion tunnel is circular, and its diameter D0 = 12m. The operation of rebuilding the diversion tunnel by adopting the method of the present invention is as follows:

[0043] ① A vertical shaft 2 connected to the diversion tunnel is set at the closed end of the diversion tunnel reconstruction section 1, the shaft is circular, its diameter D1=6m, and its centerline is perpendicular to the centerline of the diversion tunnel reconstruction section 1;

[0044] ②Set the vertical shaft orifice 3 at the connection between the vertical shaft and the reconstruction section of the diversion tunnel, and the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com