Skew correction device and recording apparatus

A technology of a recording mechanism and an inclined part, which is applied in the direction of electrographics, printing devices, electrorecording processes applying charge patterns, etc., can solve the problem of not being able to abut the door parts well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

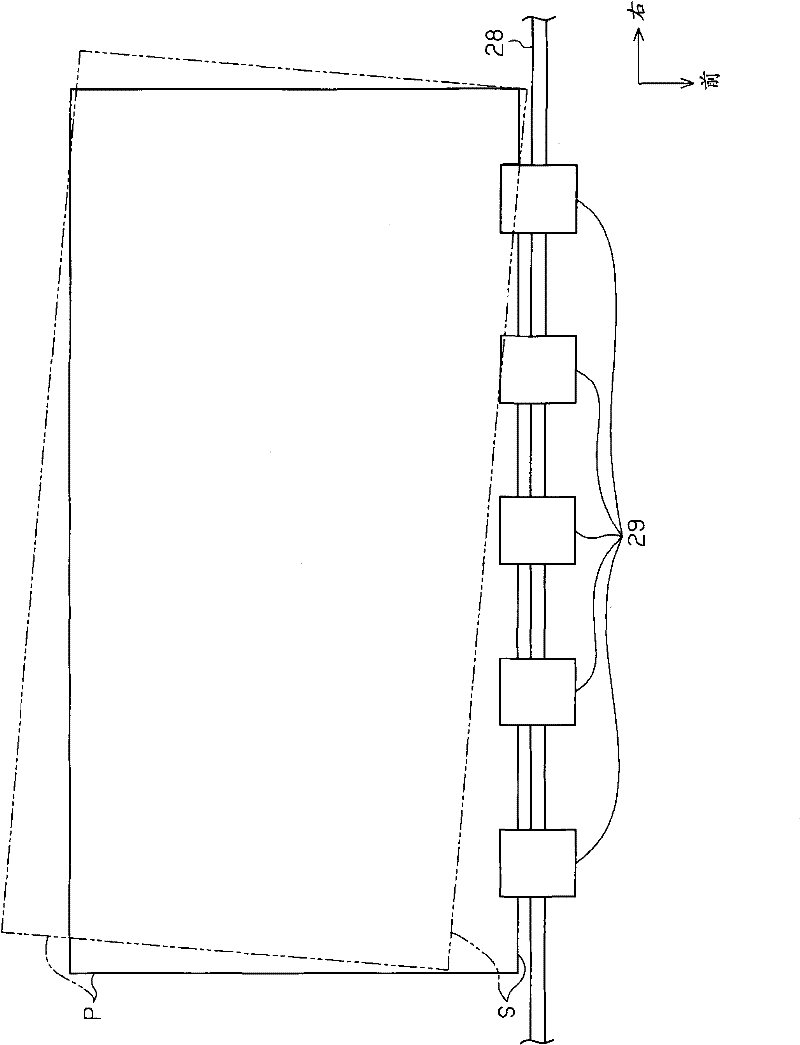

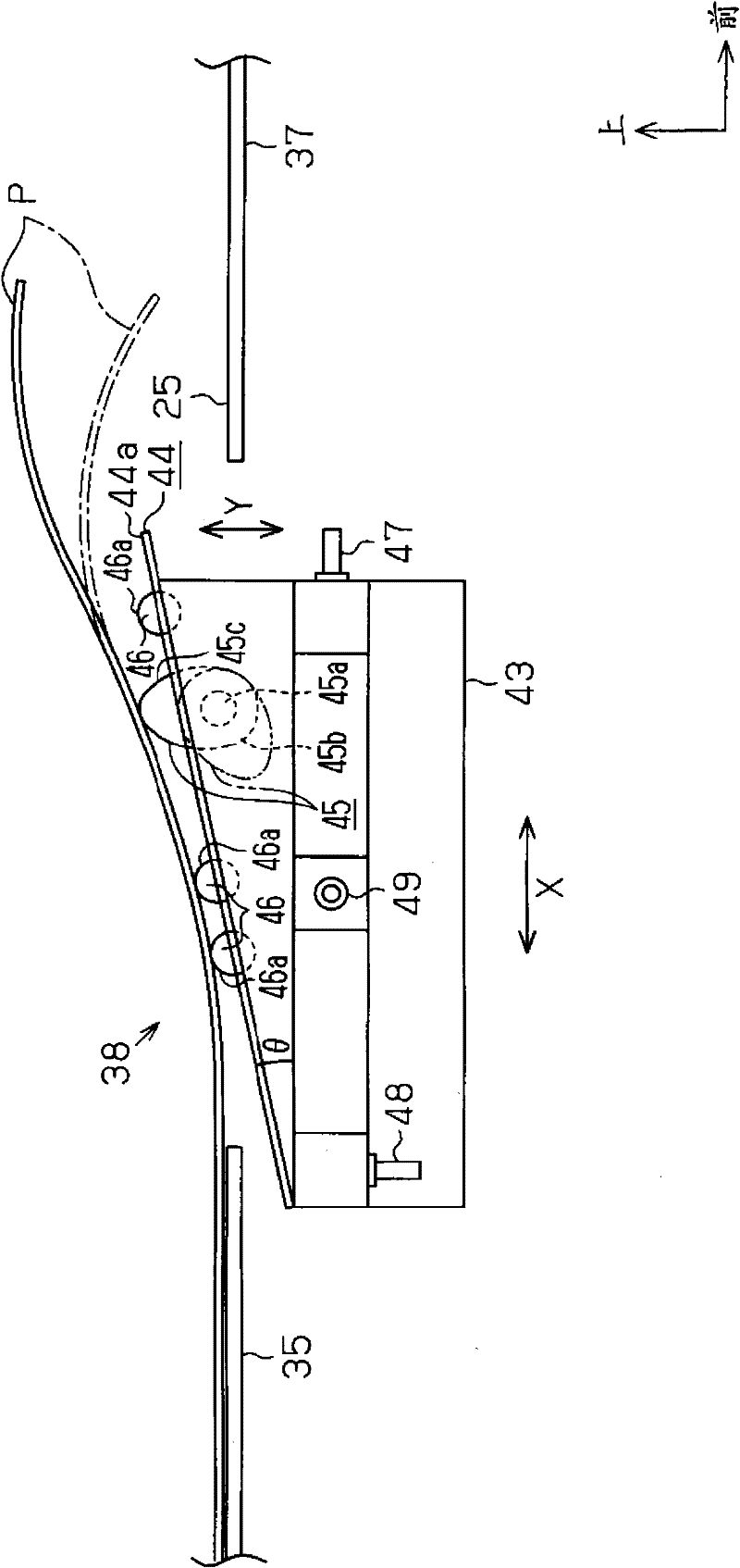

[0024] Next, use Figure 1 ~ Figure 3 , and an embodiment in which the present invention is embodied as a printer, which is one type of recording apparatus, will be described. In addition, in the following description, when referring to "front-rear direction", "left-right direction", and "up-down direction", it is based on the direction indicated by the arrow in each figure.

[0025] figure 1 The illustrated printer 11 is a large inkjet printer capable of printing corresponding to a size of about A1 or B1. The printer 11 includes a main body frame 12 , and is provided on the rear side of the main body frame 12 with a placement unit 13 on which a sheet P such as recording paper can be placed.

[0026] Further, housed in the main body frame 12 are: a pull-out roller 14 for pulling out the sheet P set in the placement section 13; a skew correction device 15 for correcting the position of the sheet P being pulled out; and a printer. The device 16 serves as a recording mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com