An integrated vehicle lubrication device

An integrated, vehicle technology, applied in the field of vehicle lubrication system, can solve the problems of heavy component weight and large space size of the lubrication system, and achieve the effects of weight reduction, system function integration, and reliability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

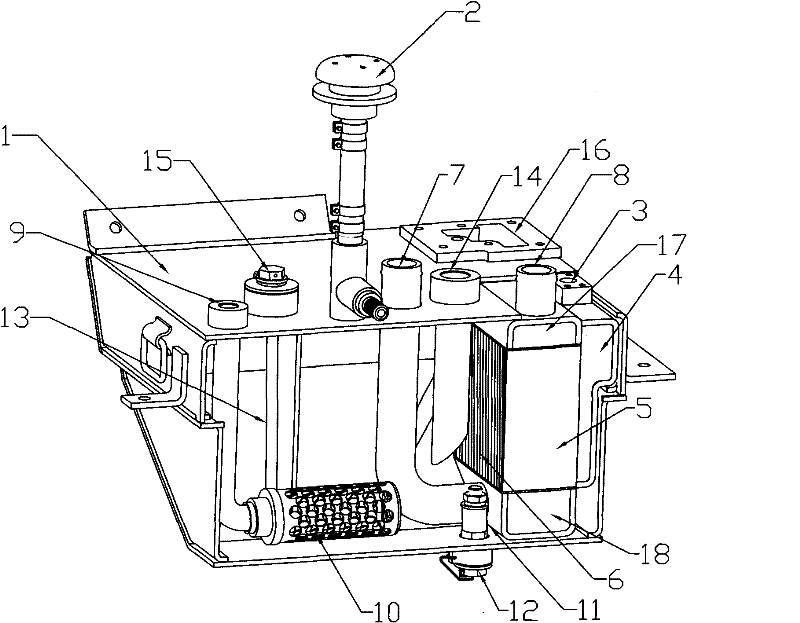

[0017] When the lubricating oil tank is being maintained, use the oil drain port 12 to release the lubricating oil. Since the power transmission system will be worn during the work process, many iron filings will fall into the lubricating oil, which will cause damage to the system. Use the oil drain port 12 to drain the oil. The magnet 11 can remove the iron filings in the lubricating oil.

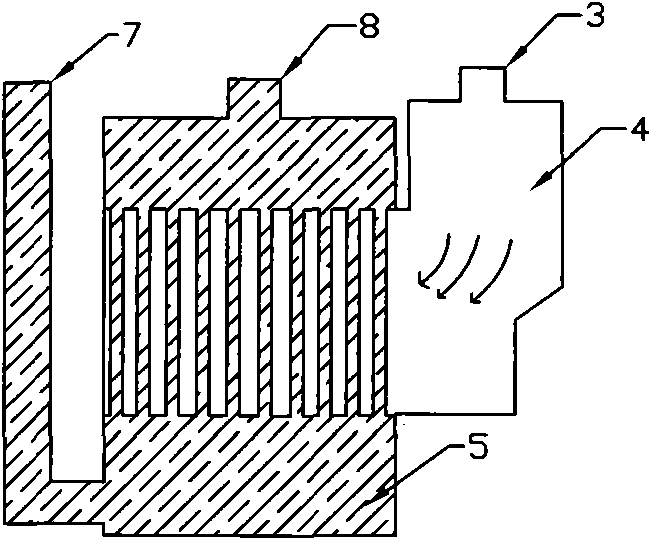

[0018] The summer vehicle water-oil heat exchanger 5 utilizes the circulating cooling water of the engine, enters by the water inlet pipe 8, cools the high-temperature lubricating oil in the work, and flows out through the water outlet pipe 7. In the initial stage of winter vehicle start-up, the lubricating oil temperature is relatively low. The circulating cooling water of the engine is heated by the vehicle heating device, and the heated circulating cooling water enters the lubricating oil tank 1 to preheat the lubricating oil to ensure that the lubricating oil Keep it in a stable workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com