Bearing system for printing pressing and printing press thereof

A technology for printing machines and flexographic printing machines, which is applied to printing machines, general parts of printing machinery, rotary printing machines, etc., and can solve problems such as no longer ensuring that the bearing system is loosened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

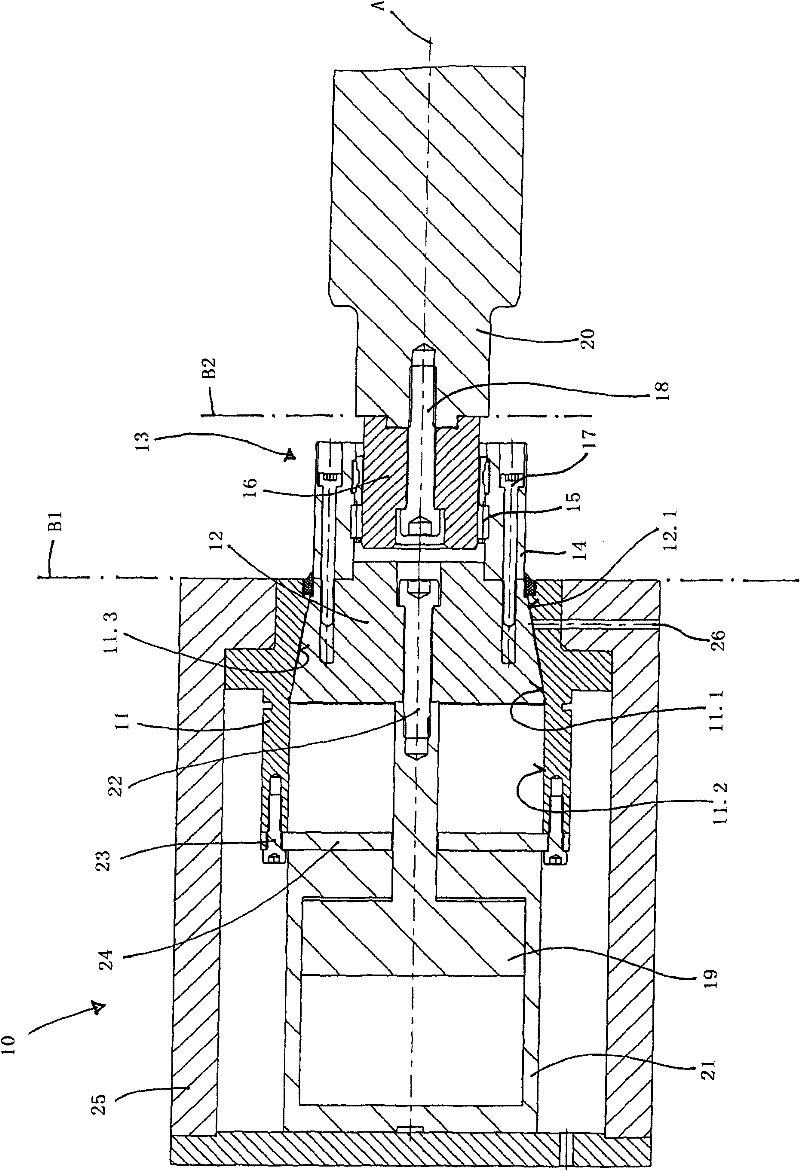

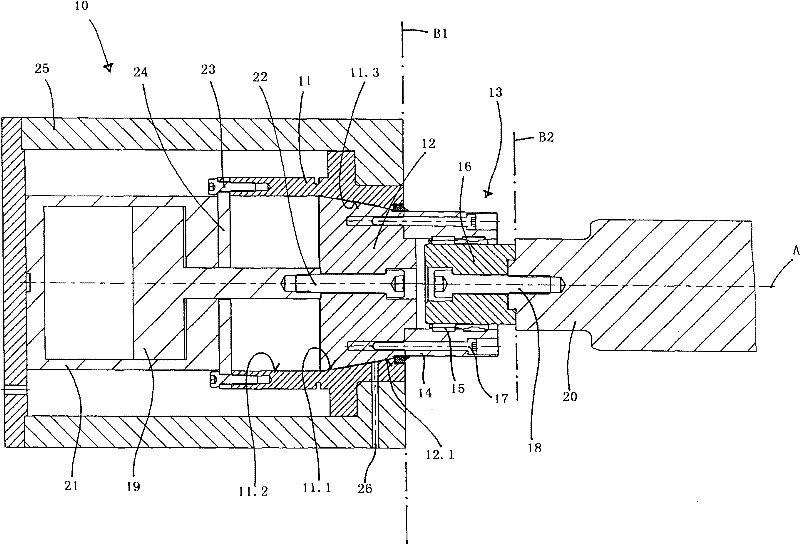

[0020] The bearing system 10 shown comprises a first housing part 11 and a second housing part 12 guided axially within the first housing part 11 . The second housing part 12 is solid and has an outer circumferential surface extending conically over its entire axial extension. The cone of the second housing part 12 is surrounded by a correspondingly conically running inner peripheral region 11.1 of the first housing part 11, which simultaneously serves as an axial stop. On the conical inner peripheral area 11.1 of the first housing part 11, a cylindrical inner peripheral area 11.2 is connected, and the inner peripheral area 11.2 encloses the following cavity, and the cone of the second housing part 12 is for loosening The bearing system can be pulled back into this cavity. For the axial displacement required for this purpose, the second housing part 12 is connected via a piston rod to a pneumatically actuatable piston 19 . The piston 19 is guided axially displaceably in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com