Abrasive rinsing machine

A technology of abrasive water and washing machines, applied in the direction of conveyor objects, packaging, chemical instruments and methods, etc., can solve the problems of inability to remove dust, low production efficiency, slow washing speed, etc., and achieve convenient operation and maintenance, simple structure, and washing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

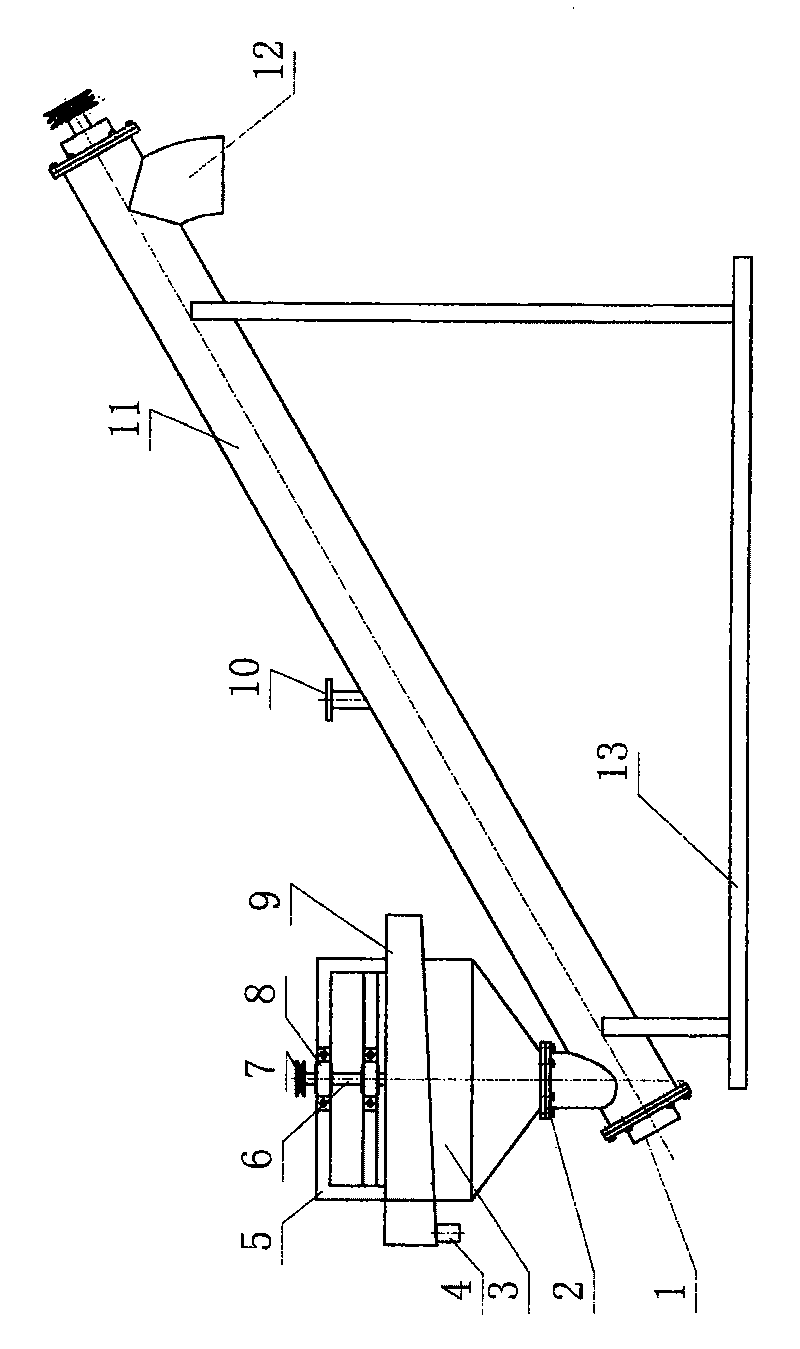

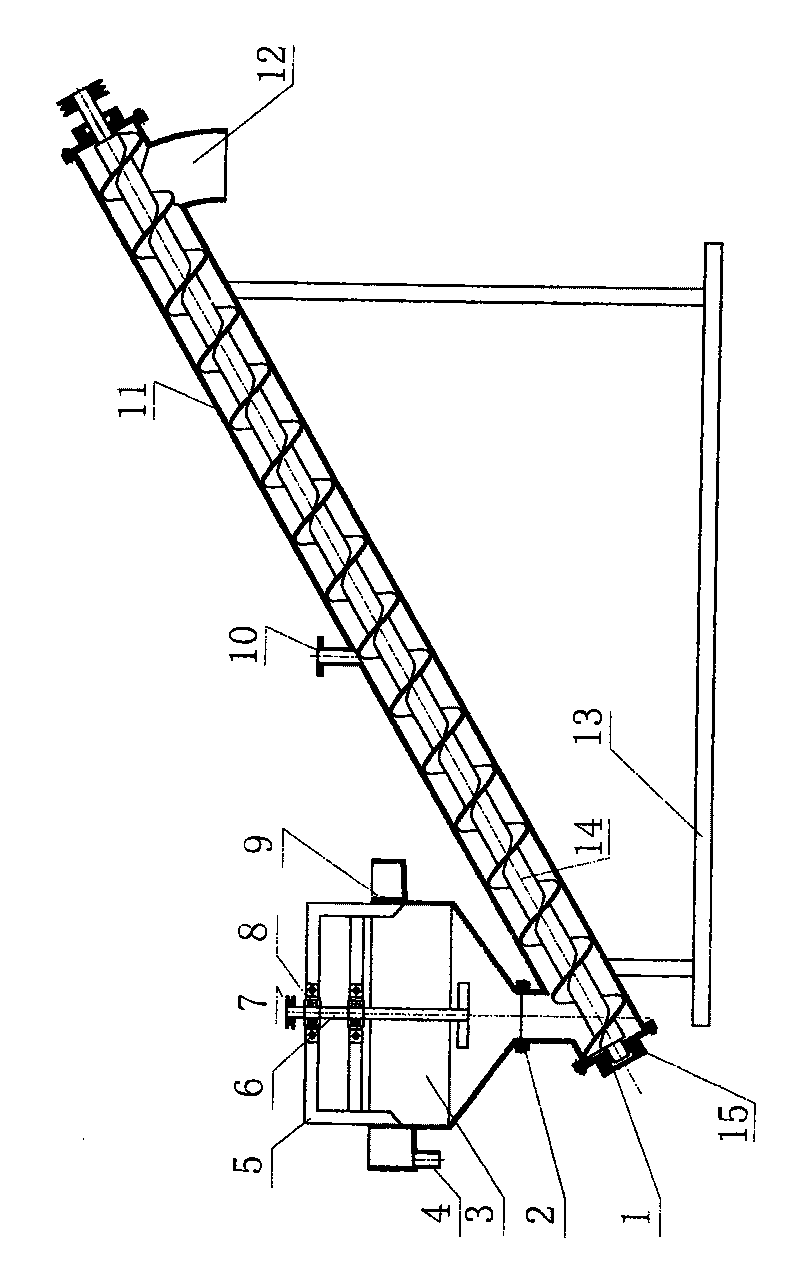

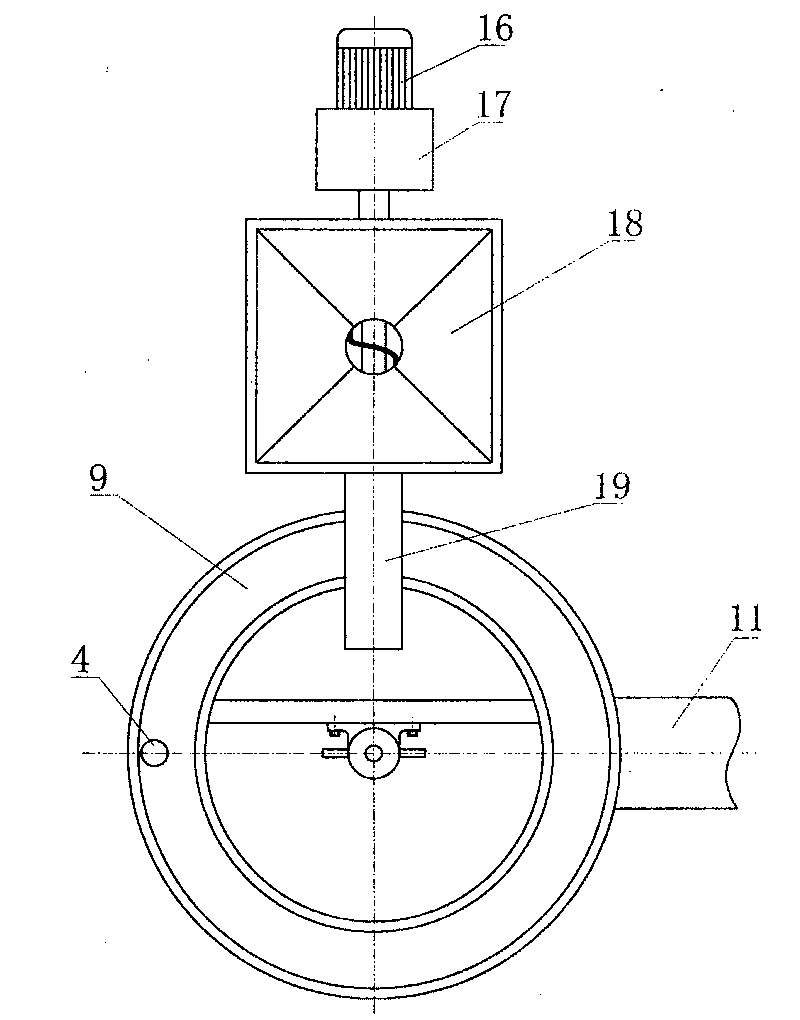

[0015] Such as figure 1 , figure 2 , image 3 Shown, 13 among the figure is support, is fixed with screw conveyer 11 on support 13. The top of the screw conveyor 11 is provided with a water inlet 10; the lower side of one end of the screw conveyor 11 is provided with a discharge port 12; one end of the screw 14 installed in the screw conveyor 11 is fixed with a pulley so as to be connected with the power, and the screw conveys The top of the other end of the device 11 is connected with the lower end of the mixing cylinder 3, and the inner cavity of the mixing cylinder 3 communicates with the inner cavity of the screw conveyor 11; a bracket 5 is fixed on the top of the mixing cylinder 3, and a bracket 5 is fixed on the bracket 5 The bearing 8 and the agitator 6 are fixed deep into the mixing cylinder 3 by the bearing 8; an overflow groove 9 is annularly fixed on the outside of the mixing cylinder 3, and an overflow port 4 and an overflow groove are arranged below the overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com